Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat)

Specifications of Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat

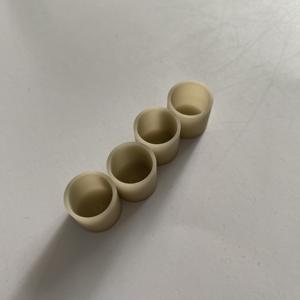

These Light Weight Aluminum Nitride (AlN) ceramic crucibles and boats are important for requiring high-temperature tasks. They handle severe heat extremely well. Crucibles resemble little mugs. They are best for melting or holding percentages of molten metal or various other products firmly. AlN ceramic watercrafts are long, flat, rectangle-shaped trays. They carry wafers or samples continuously through heater home heating zones.

Aluminum Nitride ceramic offers superb thermal conductivity. This residential property lets warmth move with the material quick and equally. Your products warm consistently. Unexpected temperature changes hardly ever break these items. This thermal shock resistance is vital for lots of procedures. They stand up to deterioration as well. Solid acids and bases normally do not damage them. Molten metals like aluminum, gallium, or copper likewise won’t respond with AlN. This keeps your products pure.

The material is extremely solid mechanically. It maintains its shape under heavy lots at high temperatures. Crucibles and boats will not flex or flaw quickly. This dimensional security is important for accurate job. AlN is additionally an excellent electrical insulator. It avoids unwanted electric currents during heating. This is important for semiconductor handling.

These items work reliably in vacuum cleaner environments. They likewise perform well under protective gases like nitrogen or argon. You can utilize them repetitively. Their longevity gives excellent worth over time. Regular applications include crystal development, metal handling, and semiconductor annealing. They are likewise usual in sintering and various research study laboratories. Light weight aluminum Nitride porcelains offer a dependable option for critical thermal processes.

(Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat)

Applications of Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat

Aluminum nitride ceramic crucibles and watercrafts manage laborious. They take care of heats and extreme chemicals well. These ceramic tools are essential in many markets. They are extremely secure and pure.

Aluminum nitride crucibles are strong containers. They are made use of to thaw metals and other products. These crucibles work well with reactive materials. Gallium arsenide processing utilizes them. They are additionally helpful for expanding crystals. The crucibles do not react with the melt. This keeps the product pure. Semiconductor manufacturers count on this pureness. They additionally help sintering unique powders. Crucibles require to last. Aluminum nitride lasts a very long time also under stress.

Aluminum nitride ceramic boats are trays. They carry things through high-heat furnaces. Semiconductor wafer processing uses these watercrafts. They hold silicon wafers during diffusion and annealing. The boats need to not pollute the wafers. Aluminum nitride is clean. It also moves warmth quickly. This ensures even heating. LED manufacturing makes use of these boats as well. They hold components for procedures like MOCVD. The watercrafts remain stable under rapid temperature changes. This is crucial.

Both crucibles and watercrafts are fantastic for heat. Light weight aluminum nitride moves warm much better than lots of porcelains. This helps processes run quicker. It also conserves power. They stand up to chemical assault. Acids and bases do not damage them easily. Molten salts likewise cause little harm. This makes them last. They are strong also at extremely high temperatures. They won’t deform or damage conveniently. Electric insulation is an additional plus. They do not carry out electricity. This is risk-free around digital parts.

These ceramics are crucial for modern-day production. They sustain making semiconductors, LEDs, and advanced products. Their high pureness prevents problems. Their strength makes sure dependability. Manufacturing facilities use them daily. Labs depend upon them for research study. They resolve issues with warm and corrosion.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat

What’s Aluminum Nitride ceramic good for?

Aluminum Nitride ceramic handles extreme heat well. It resists chemical corrosion too. Crucibles and boats made from it work great for high-purity metal melting, crystal growth, and semiconductor processing. It won’t easily crack under sudden temperature changes either.

How hot can AlN crucibles and boats get?

They work reliably long-term up to about 1800°C (3272°F) in inert atmospheres like nitrogen or argon. Short bursts might reach higher, maybe 2200°C (3992°F), but check the specific product details first. Going too high damages them.

Can I use AlN with reactive metals?

Be careful. Aluminum Nitride resists molten salts and many metals. But avoid molten aluminum, lithium, or alkaline earth metals like calcium. These can react with the AlN surface, causing damage. Stick to inert gases or vacuum for best results.

How do I clean AlN crucibles and boats?

Clean them gently after cooling. Use warm water and mild detergent first. For stubborn residues, try dilute acids like nitric or hydrochloric acid. Avoid abrasive scrubbing. Never use strong alkalis like hot sodium hydroxide. Those etch the surface.

What’s the difference between a crucible and a boat?

Shape matters. Crucibles are deep cups for holding and melting materials. Boats are shallow, open trays. They’re ideal for transporting samples inside furnaces or for thin film coating processes. Both are made the same way, sintered at high temperatures. Choose based on your specific task.

(Aluminum Nitride Ceramic Crucible and Aluminum Nitride Aln Ceramic Boat)

REQUEST A QUOTE

RELATED PRODUCTS

High Heat Conductivity AlN Aluminum Nitride Ceramic Sheet

Aln Aluminium Nitride Ceramic Substrate Chip Shim for Power Modules

Precision Laser Cut Thin Aluminum Nitride Plate Aln Ceramic Substrate

ALN High Thermal Conductivity Aluminum Nitride Ceramic Block

Laser Cutting Processing PCB Plate Aln Aluminum Nitride Ceramic Substrate