Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Aluminum Nitride Insulator ALN Ceramic Disc)

Specifications of Aluminum Nitride Insulator ALN Ceramic Disc

The Aluminum Nitride Insulator ALN Ceramic Disc is a high-performance product developed for innovative commercial applications. It integrates remarkable thermal conductivity with strong electrical insulation. The thermal conductivity of ALN ceramic reaches 170-200 W/mK, outperforming typical alumina porcelains. This makes it ideal for managing warm in high-power digital devices. The product operates reliably in temperature levels up to 1300 ° C, keeping architectural stability under severe conditions. Its low thermal expansion coefficient matches materials like silicon, lowering stress and anxiety in layered settings up.

ALN ceramic discs show outstanding electric insulation, with a volume resistivity exceeding 10 ^ 14 Ω · cm. This stops present leak in high-voltage settings. The dielectric stamina mores than 15 kV/mm, making certain safety and security in circuits with substantial voltage differences. The material resists chemical rust from acids, antacid, and molten steels. This toughness suits severe industrial settings.

The mechanical homes include high hardness (1200 HV) and compressive stamina (2000 MPa). These qualities allow lasting usage in rough or high-pressure circumstances. ALN ceramic is non-toxic and adhere to RoHS and REACH criteria. It fulfills needs for green manufacturing.

Criterion disc diameters vary from 10 mm to 150 mm, with densities between 0.5 mm and 10 mm. Custom shapes and sizes are offered for specialized applications. Surface area finishes consist of brightened, lapped, or as-sintered alternatives. Refined surfaces decrease friction in precision parts.

Production includes sintering aluminum nitride powder at heats. This procedure guarantees high thickness (over 3.3 g/cm FOUR) and marginal porosity. The outcome is a homogeneous microstructure with consistent performance. ALN ceramic discs are compatible with thin-film metallization methods. This allows combination into circuits or heat sinks by means of soldering or brazing.

Applications span electronics, aerospace, automotive, and energy sectors. Usual usages include heat spreaders, semiconductor substrates, LED cooling bases, and RF microwave windows. The product’s thermal administration abilities boost effectiveness in lasers, power components, and electrical car components. ALN ceramic discs are packaged securely to prevent damage during delivery. Personalized specs can be tailored to satisfy project demands.

(Aluminum Nitride Insulator ALN Ceramic Disc)

Applications of Aluminum Nitride Insulator ALN Ceramic Disc

Light Weight Aluminum Nitride (ALN) ceramic discs are extensively used in sectors requiring high thermal conductivity and electrical insulation. These materials handle severe warmth and resist chemical corrosion. ALN ceramic discs are common in electronics. They manage heat in silicon chips and semiconductor tools. This prevents getting too hot and improves gadget dependability. LED lights systems utilize ALN discs. They move warm far from LED chips, extending their lifespan. Power electronics rely on ALN discs. Electric vehicles and renewable energy systems use them in power components. They manage high voltages and temperature levels efficiently. ALN ceramic discs are made use of in automotive sensors. They make certain exact readings in harsh engine settings. Aerospace applications consist of radar systems and satellite components. ALN discs hold up against heats and radiation precede. Telecommunications devices makes use of ALN for radio frequency parts. The material’s reduced signal loss boosts efficiency in high-frequency applications. Industrial heating unit use ALN discs as insulators. They secure delicate components from severe warm in heating systems and reactors. ALN ceramic discs are used in laser modern technology. They cool laser diodes and preserve steady procedure. Clinical tools take advantage of ALN’s biocompatibility. It is used in equipment needing electric insulation and warmth resistance. ALN discs are found in high-power electronics. They protect against electrical leakage in high-voltage applications. The product’s durability makes it ideal for rough settings. ALN ceramic discs are cost-efficient for mass production. They reduce the requirement for complex air conditioning systems. Makers pick ALN for its mix of thermal and electrical residential properties. ALN discs work with sophisticated manufacturing strategies. This permits specific shaping for personalized applications. Industries worth ALN ceramic discs for enhancing efficiency and integrity. They fix heat monitoring obstacles in modern-day technology. ALN continues to change typical materials in demanding applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Nitride Insulator ALN Ceramic Disc

Aluminum Nitride (AlN) ceramic discs are advanced materials used in electronics. People often ask five common questions.

What is Aluminum Nitride used for? It is used in heat sinks, circuit substrates, and high-power electronic devices. It works in semiconductors, LED lighting, and radio frequency equipment. The material handles heat well and insulates electricity effectively.

How does Aluminum Nitride compare to alumina? Aluminum Nitride conducts heat better than alumina. It transfers heat up to 10 times faster. It also resists thermal expansion more. This makes it better for devices needing quick heat removal.

Why is Aluminum Nitride good for high temperatures? It stays stable at temperatures over 1,300°C. It resists chemical corrosion. It does not crack under sudden temperature changes. These traits make it ideal for aerospace and automotive applications.

Can Aluminum Nitride be shaped into complex parts? Yes. Specialized diamond tools cut and grind it precisely. The material is brittle. Careful handling is needed during machining. Custom shapes are possible for specific technical needs.

Are there drawbacks to using Aluminum Nitride? It costs more than alumina. Its brittleness requires careful handling. It might not suit budget-focused projects. Proper design reduces risks of cracking during installation.

(Aluminum Nitride Insulator ALN Ceramic Disc)

REQUEST A QUOTE

RELATED PRODUCTS

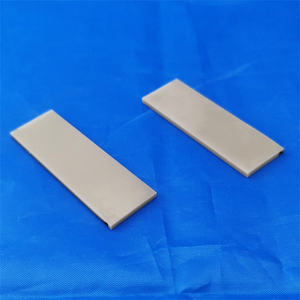

Low Dielectric Loss High Thermal Conductivity Aln Aluminum Nitride Ceramic Pad /Sheet

High Quality Porcelain Ceramic Substrate Sheet High Temperature Resistance Aluminum Nitride Heat Sink ALN Ceramic Plate

Machinable Aluminum Nitride (AIN) Ceramic Square Rod

Aln Alumina Nitride Ceramic Plate / Alumina Nitride Ceramic Substrate / Alumina Nitride Sheet

Heat Sink Aluminum Nitride Ceramic Substrate