Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube)

Specifications of Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube

This item is a high-performance light weight aluminum nitride (ALN) ceramic tube made for IGBT and MOS tube applications. It meets strict needs in high-power digital systems. The product is light weight aluminum nitride ceramic. This ceramic has exceptional thermal conductivity. It reaches up to 170-180 W/m · K. This guarantees effective warm dissipation popular environments. The electric insulation residential or commercial properties are strong. The quantity resistivity exceeds 10 ¹⁴ Ω · centimeters. This prevents current leak. Television is made for high-temperature security. It runs accurately from -50 ° C to 850 ° C. Thermal growth is reduced. It matches silicon wafers closely. This reduces stress in semiconductor configurations.

Television has a plus size. The external diameter varieties from 30 mm to 150 mm. Sizes are customizable between 50 mm and 500 mm. Wall density is precise. Tolerances remain within ± 0.5% of the defined dimension. Surface area finish is smooth. Ra worths are under 0.4 μm. This lessens friction and wear. The framework is dense. Porosity is below 0.1%. This improves mechanical stamina. Flexural stamina surpasses 300 MPa. The solidity is high. It gets to 12 GPa on the Vickers scale.

Manufacturing utilizes high-purity aluminum nitride powder. The procedure consists of innovative sintering methods. This makes certain uniformity in density and performance. The tube withstands chemical corrosion. It takes care of acids, alkalis, and molten metals. It is compatible with vacuum settings. Outgassing prices are very little. This suits high-vacuum applications.

Applications consist of IGBT modules, power semiconductor packaging, and laser diode real estates. It operates in electrical lorries, renewable energy systems, and aerospace electronic devices. The style concentrates on resilience. It stands up to thermal cycling and mechanical shocks. Personalized forms and finishes are available. Alternatives consist of metallization for brazing or soldering.

Testing complies with international standards. Each set goes through thermal, electric, and mechanical checks. Accreditations consist of ISO 9001 and RoHS conformity. Packaging makes use of anti-static materials. This avoids damage throughout delivery. Technical assistance is given. Help covers integration and efficiency optimization.

(Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube)

Applications of Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube

Huge dimension high accuracy aluminium nitride (ALN) ceramic tubes offer crucial duties in power electronic devices, particularly for IGBT and MOS tube applications. These components manage high-power procedures in industries such as renewable energy, electrical cars, and commercial automation. ALN ceramic attract attention for its exceptional thermal conductivity, electrical insulation, and mechanical security, making it optimal for requiring environments.

Thermal monitoring is a main problem in IGBT and MOS modules. ALN tubes successfully move warm away from delicate elements. This stops overheating and guarantees stable efficiency. High thermal conductivity allows warm dissipation without requiring bulky cooling systems. This conserves space and decreases layout complexity in compact gadgets.

Electric insulation is another vital benefit. ALN ceramic resists high voltages, stopping short circuits in power components. Its dielectric toughness continues to be steady also under severe temperature levels. This integrity prolongs the life expectancy of digital systems, decreasing upkeep prices and downtime.

Mechanical resilience issues in extreme operating problems. ALN tubes resist thermal shock, rust, and wear. They preserve architectural stability throughout rapid temperature level adjustments, common in high-power biking applications. This durability makes sure constant efficiency over time, also in rugged industrial settings.

Precision production is crucial for ALN ceramic tubes. Tight resistances make sure correct fit and placement in IGBT and MOS settings up. Smooth surfaces decrease friction and wear during installation or operation. Customizable dimensions fit varied design needs, sustaining both standard and specialized applications.

Making use of ALN ceramic supports innovations in energy effectiveness. Boosted heat dissipation lowers power loss in power conversion systems. This aligns with worldwide demands for greener innovations and sustainable power remedies. Industries gain from lowered operational costs and improved system reliability.

Compatibility with sophisticated manufacturing strategies allows smooth integration into modern electronic devices. ALN tubes function well with automated setting up procedures, supporting high-volume production. Their chemical inertness ensures compatibility with different soldering and bonding materials, streamlining production operations.

Big dimension ALN tubes resolve difficulties in high-power thickness applications. Their capacity to handle extreme problems makes them indispensable in next-generation power electronic devices. From electric automobile inverters to commercial electric motor drives, these components make it possible for more secure, much more reliable, and durable systems.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube

1. What is the main use of the Big Size High Precision Aluminium Nitride Tube?

This product is mainly used in IGBT and MOS tube modules for thermal management. It transfers heat efficiently, reduces operating temperatures, and improves device reliability. Its high precision ensures tight integration with electronic components, preventing performance loss from poor fitting.

2. Why pick Aluminium Nitride over other ceramic materials?

Aluminium Nitride (ALN) has higher thermal conductivity than alumina or aluminum oxide. It moves heat faster, which is critical for high-power devices like IGBT modules. ALN also has a thermal expansion coefficient close to silicon, reducing stress between layers. It resists corrosion and electrical breakdown better than many alternatives.

3. How does high precision affect performance in ALN tubes?

High precision machining guarantees exact dimensions and smooth surfaces. This eliminates gaps between the tube and connected parts, boosting heat transfer. Even minor flaws can cause hot spots or mechanical failure, so precision ensures stability in demanding applications like industrial inverters or EV power systems.

4. Can this ALN tube handle extreme temperatures?

Yes. ALN ceramic works reliably in environments from -40°C to over 1000°C. It doesn’t degrade under rapid temperature changes, making it suitable for aerospace, automotive, and heavy machinery applications. Its low thermal expansion prevents cracking even during sudden heating or cooling.

5. What precautions are needed when installing ALN tubes?

Avoid mechanical impact during handling—ALN is hard but brittle. Ensure surfaces are clean and free from debris before installation. Use compatible adhesives or bonding methods to prevent chemical reactions. Follow torque specifications if screws or clamps are involved. Store in dry conditions to minimize moisture absorption before use.

(Big Size High Precision Aluminium Nitride Tube / ALN Ceramic for IGBT / MOS Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity 99.95% Aluminum Nitride AlN Spherical Powder 3-5um Ceramic Microspheres Durable Heat Conductive Material

Customizable 170W Aluminium Nitride Ceramic Roller ALN Parts Insulator for Electronic

High Quality 99.9% 90-120um Aluminum Nitride Powder AlN Powder for Ceramics and Semiconductor CAS 24304-00-5

High thermal conductivity thick film aln aluminum nitride ceramic pcb and alumina pcb substrate

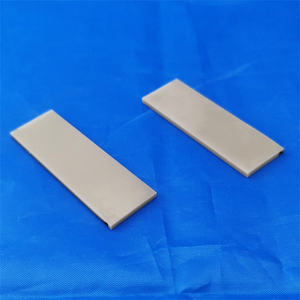

Whole Aluminum Nitride Thermal Conductive Plate Aln Electrical Insulation Ceramic Heat Sink Sheet Substrate