Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

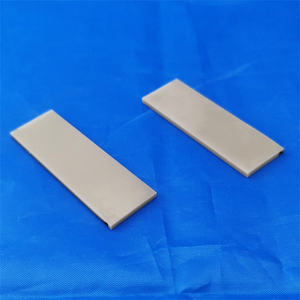

Overview of Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use)

Specifications of Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use

Custom-shaped light weight aluminum nitride ceramic components serve demanding commercial demands. These parts are made from a special technical ceramic. Light weight aluminum nitride offers one-of-a-kind properties essential for innovative applications. High thermal conductivity is an essential advantage. These components move warmth away extremely successfully. They prevent overheating in sensitive tools. Superb electrical insulation is an additional significant benefit. They dependably stop electricity from flowing where it shouldn’t. This happens even at extremely heats.

The ceramic is extremely difficult. It stands up to wear over extended periods. It also stands well versus harsh chemicals. Deterioration is rarely a trouble. This product takes care of extreme thermal shock. Abrupt temperature level changes will not easily crack it. These homes make AlN ceramics optimal for tough environments.

We produce parts in certain forms you call for. Facility geometries are possible. Precision machining accomplishes limited tolerances. We meet specific dimensional specifications. This guarantees components fit flawlessly right into your setting up. Usual usages include semiconductor production tools. They are important in high-power electronic devices. Laser systems frequently utilize them also. They function well in automotive sensors and aerospace components.

Integrity is crucial. We examine our materials extensively. Consistent quality is guaranteed. Parts perform under high stress. They last longer, minimizing downtime. You obtain reputable performance for essential operations. These parts resolve heat administration issues. They protect delicate digital parts. They enable higher power thickness. They improve general system efficiency.

(Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use)

Applications of Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use

Aluminum nitride ceramic parts made to custom shapes offer vital industrial requirements. This material deals with extreme warmth extremely well. It relocates warm away from critical parts successfully. Light weight aluminum nitride additionally obstructs electrical energy entirely. It does not react with numerous chemicals. These residential properties make it important for tough jobs.

Semiconductor producing uses custom-made light weight aluminum nitride parts widely. Wafer handling equipment requires high warmth transfer. Aluminum nitride holders and insulators function perfectly right here. They maintain electric systems risk-free while managing warmth. Laser systems also depend upon this ceramic. Laser diode providers made from light weight aluminum nitride quit overheating. This shields delicate laser components.

Power electronic devices depend greatly on custom aluminum nitride shapes. Instruments like IGBTs create significant warmth. Light weight aluminum nitride warm spreaders and substratums pull this heat away fast. They prevent tool failure. This maintains power converters and motor drives running smoothly. The electric insulation is vital too. It stops hazardous shorts.

High-temperature sensors need robust products. Light weight aluminum nitride excels here. Custom sensing unit real estates endure warm, destructive settings. They safeguard fragile sensor elements inside. The automobile market uses these sensing units. They keep track of exhaust gases and engine conditions precisely. Customized forms fit limited rooms in modern-day lorries. Aluminum nitride parts operate accurately for extended periods. They endure vibrations and temperature swings.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use

What makes aluminum nitride special?

Aluminum nitride handles heat very well. It moves heat away fast. This matters in hot electronics. It also blocks electricity safely. It doesn’t get bigger when hot. This keeps parts stable. It’s strong and lasts long.

Why get custom shapes?

Standard parts often don’t fit right. Machines need exact sizes. Custom shapes solve this. They fit tight spaces perfectly. They connect to other parts smoothly. This boosts machine performance. It cuts down on failures.

Where are these parts used?

They go into electronics making machines. They hold hot silicon wafers. They work in high-power lights. They help in radar systems. They are in laser tools too. Any place needing heat control uses them.

How tough is aluminum nitride?

It’s very hard. It resists scratches. It handles high heat without cracking. It deals with chemicals okay. It doesn’t wear out fast. It’s reliable for tough jobs. Expect it to last.

How do you ensure good parts?

Work with skilled makers. They know ceramics well. They use precise shaping methods. They test every part carefully. They check size and strength. They test heat flow. Ask for test reports. See samples first.

(Custom-Shaped Aluminum Nitride Ceramic Parts for Industrial Use)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Nitride Plate Ceramic Substrate Heater AlN Heating Element

99.7% High-Purity Factory Supply Whole 1-10 Ain Aluminum Nitride Powder for Ceramics

Aluminum Nitride Ceramic Machinable Ceramic Plate Part

Aluminum Nitride Ceramic Sheet Aluminum Nitride Chip Aluminum Nitride Aln Ceramic Plate

High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Crucible