Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

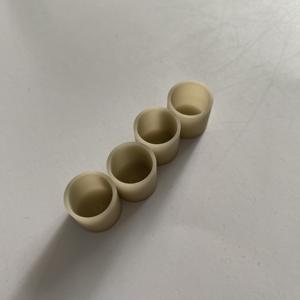

Overview of Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture)

Specifications of Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture

Personalized 99% high pureness aluminum nitride ceramic (AlN) meets demanding thermal monitoring requirements. This material provides remarkable efficiency. We customize it specifically for your high warmth applications. The core attribute is the 99% minimum purity level. High pureness makes sure trusted thermal conductivity. It also minimizes unwanted chain reaction throughout use.

Thermal homes are outstanding. The thermal conductivity gets to 170-180 W/mK. This relocates heat away very quick. It avoids unsafe locations. The product likewise takes care of sudden temperature changes well. Its coefficient of thermal expansion closely matches silicon. This is important for electronics. It lowers anxiety and stops splitting.

Mechanical strength is solid. It provides good structural support. The material resists wear and abrasion successfully. Electric insulation is another vital benefit. It safely separates parts also at high voltages. This makes it excellent for power electronic devices.

We tailor sizes and shapes for you. Inform us your specific requirements. We produce complex geometries. We meet limited dimensional tolerances. Surface area finishes are customized also. We provide choices from common to mirror polish. We can maker the ceramic specifically. We develop openings, threads, and unique features.

This AlN ceramic addresses warm issues in many areas. It works perfectly in semiconductor production tools. Utilize it for wafer chucks, heating units, and electrostatic chucks. LED production benefits significantly. It offers in warmth sinks and mounting plates. Power components utilize it for substratums and insulators. Laser systems need it for cooling down components. High-power electronics rely upon its insulation.

(Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture)

Applications of Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture

Custom-made 99% high pureness light weight aluminum nitride ceramic solves tough heat problems popular production. Warm accumulation problems parts and slows manufacturing. AlN ceramic manages warmth exceptionally well. It relocates heat away from sensitive parts fast. This maintains points running cooler and extra accurately.

Its high purity, 99%, is important. Impurities weaken thermal efficiency. Our AlN ceramic deals superb thermal conductivity. This is better than basic alumina porcelains. It also supplies strong electric insulation. This mix is hard to locate in other materials.

Semiconductor producing requirements this product. Chip making entails extreme warm. AlN substratums and components handle this heat properly. They safeguard delicate circuits. This causes much better chip returns and performance.

Power electronic devices likewise benefit considerably. Tools like IGBT components and power converters generate considerable warmth. AlN warmth sinks and insulators draw warmth away successfully. This avoids overheating failings. Equipment lasts longer and works better.

LED lighting makes use of AlN crucially. High-power LEDs create great deals of warm in small areas. AlN substrates conduct this warm rapidly. They prevent the LED chips from getting also hot. This maintains light result and prolongs LED life.

Laser technology relies on excellent thermal monitoring. High-power lasers produce intense warm. AlN components function as heat spreaders. They make certain steady laser procedure and beam high quality. Downtime is minimized.

Personalized shapes are necessary. Every application has distinct component demands. We exactly form the AlN ceramic to your exact specifications. This ensures an ideal fit and optimum thermal transfer. Facility geometries are feasible. This modification delivers the most effective performance for your specific thermal challenge. It makes your high-heat manufacturing processes more efficient and dependable.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture

What makes 99% purity important for Aluminum Nitride?

High purity is critical. It ensures the best thermal performance. Impurities hinder heat flow. Our 99% purity guarantees maximum heat transfer. This is vital for demanding thermal applications.

How good is its thermal conductivity?

Aluminum Nitride ceramic moves heat exceptionally well. It performs much better than standard alumina. It approaches some metals. This makes it perfect where heat buildup causes problems. It keeps components reliably cool.

Can you make custom shapes and sizes?

Yes. We specialize in custom fabrication. Tell us your exact requirements. We produce complex geometries and precise dimensions. You get parts tailored exactly for your equipment. Standard sizes are also available.

Is this material strong and durable?

Absolutely. Aluminum Nitride is very hard. It resists wear effectively. It handles high temperatures easily. It won’t degrade quickly under thermal stress. This ensures long-lasting performance in tough conditions.

What applications is it best suited for?

Its high thermal conductivity and electrical insulation are key. It excels in electronics needing heat spreaders. Use it for semiconductor chucks and laser diode bases. It’s ideal for high-power LED mounts and other demanding thermal management tasks.

(Customized 99% High Purity Ain Aluminum Nitride Ceramic for High Thermal Manufacture)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Nitride Ceramic Sheet Aluminum Nitride Chip Aluminum Nitride Aln Ceramic Plate

Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Customized High Thermal Conductivity Aln Aluminum Nitride Sheet Plate

300mm Diameter Customized OEM Aluminum Nitride Wafer

Industry Electrical CNC Machining Ceramic Component Aluminum Nitride Ceramic ALN Heat Sink