Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

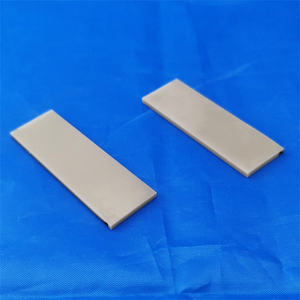

Overview of Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates)

Specifications of Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates

Factory High Pureness Aluminum Nitride (AlN) ceramic substrates are engineered for demanding incorporated circuit applications. They need phenomenal thermal efficiency and electric dependability. Our AlN product regularly attains pureness degrees surpassing 99.5%. This lessens undesirable pollutants influencing circuit habits. The vital function is high thermal conductivity, commonly 170-200 W/mK. This properly pulls heat away from sensitive IC elements. Avoiding getting too hot is essential for device life time and rate.

The material is thick. It handles challenging conditions. Density measures around 3.3 g/cm SIX. Hardness is high, roughly 12 GPa (Vickers). This makes certain mechanical toughness throughout handling and usage. Electric insulation is excellent. Quantity resistivity is more than 10 ^ 14 Ω · centimeters at space temperature level. This protects against present leak in between circuit paths. The dielectric constant is reduced, approximately 8-9 at 1 MHz. Signal loss is lessened. Signal stability remains high for rapid electronics.

The dielectric toughness is strong. It endures over 15 kV/mm. This prevents electrical failure under high voltage. The heat development price is low. It matches silicon chips well. Thermal expansion coefficient has to do with 4.5 ppm/K. This decreases anxiety at the chip-substrate user interface. Temperature level biking is a lot more reputable. Surface area high quality is really smooth. Average roughness (Ra) is less than 0.2 μm. Fine-line circuit printing functions flawlessly. Monotony is firmly managed for specific setting up.

(Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates)

Applications of Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates

Factory High Purity Aluminum Nitride (AlN) substrates are necessary for sophisticated integrated circuits. These ceramic bases manage the severe demands of contemporary electronic devices. AlN provides extraordinary thermal conductivity. This residential or commercial property is a lot higher than standard alumina ceramics. Reliable warmth removal is crucial. Powerful chips produce considerable heat. Without correct dissipation, efficiency drops and chips stop working. AlN relocates warm away promptly. This keeps circuits cooler and running dependably.

Electric insulation is another vital feature. AlN substrates stop unwanted electrical currents. This isolation protects sensitive circuit components. Signal honesty remains high. The product also reveals excellent resistance to electric breakdown. High voltages are safely managed. This is vital for power electronic devices and RF tools.

The thermal development of AlN very closely matches silicon. Silicon is the primary product for semiconductor chips. Different growth prices cause tension throughout temperature adjustments. Tension causes fractures and link failures. AlN’s comparable development actions lessens this threat. Chip add-ons stay protected over lots of heating and cooling cycles.

Production processes benefit from AlN’s properties. Slim film deposition and etching work well on its surface. The product provides a stable, level system. Accuracy circuit pattern is attainable. High purity levels guarantee no contamination. Impurities interfere with delicate semiconductor processes. Regular pureness assurances reputable substrate performance.

AlN substratums support requiring applications. Power components handle high currents and heat. RF parts run at high regularities. LED lights needs efficient thermal management. Semiconductor product packaging needs durable, shielding bases. Manufacturing Facility High Purity AlN satisfies these requirements. It makes it possible for smaller sized, quicker, extra effective electronic devices. Its thermal and electric efficiency transcends. This makes it the favored selection for innovative integrated circuits demanding dependability and effectiveness.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates

What is Aluminum Nitride and why is it used for integrated circuit substrates? Aluminum Nitride is a ceramic material. It moves heat away very well. Integrated circuits produce heat during operation. This heat must be removed quickly. Aluminum Nitride does this job better than many materials. It also stops electricity from passing through. This keeps the circuit safe. So we use it as a base layer for chips.

Why is high purity AlN important for these substrates? High purity means fewer impurities. Impurities can cause problems. They might block heat transfer. They could create electrical leaks. Pure Aluminum Nitride avoids these issues. It ensures the substrate performs reliably. This is critical for advanced electronics.

How does the thermal conductivity of AlN help integrated circuits? Thermal conductivity measures heat transfer speed. Aluminum Nitride has excellent thermal conductivity. It pulls heat from the circuit fast. This stops overheating damage. Circuits run longer without failing. That’s why it’s chosen for demanding applications.

Is Aluminum Nitride chemically stable in semiconductor environments? Yes, it is highly stable. Semiconductor manufacturing uses strong chemicals and gases. Aluminum Nitride resists corrosion from these. It doesn’t break down or react easily. This stability keeps the substrate intact during production. It ensures no contamination affects the chips.

Can AlN substrates endure high temperatures in IC manufacturing? Absolutely. Aluminum Nitride handles extreme heat. Processes like soldering reach high temperatures. AlN won’t warp or crack under these conditions. Its structure stays solid and reliable. This makes it ideal for the harsh steps in chip making.

(Factory High Purity Aln Aluminum Nitride for Integrated Circuit Substrates)

REQUEST A QUOTE

RELATED PRODUCTS

Laser Cutting Dbc Al2o3 Aln Aluminum Nitride Ceramic Substrate For Thermoelectric Research Lab

High Heat Conductivity AlN Aluminum Nitride Ceramic Sheet

High-Performance Aluminum Nitride Ceramics for Tailored Manufacturing Solutions

170W Aluminum Nitride Sheet Piece ALN Ceramic Plate with Hole for LED

Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics