Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

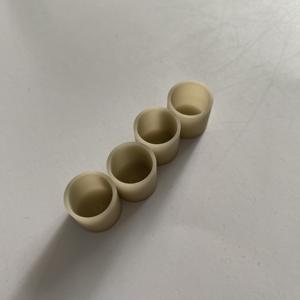

Overview of Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining)

Specifications of Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining

This crushed rock aluminum nitride ceramic deals extraordinary purity. The material gets to 99.99% purity. This high pureness level is crucial for top performance. It makes certain trusted lead to demanding applications.

The ceramic excels at relocating warmth. It possesses superb thermal conductivity. This residential or commercial property is essential for managing temperature in electronics. It additionally functions as a solid electric insulator. Electrical current does not go through it conveniently. This combination is uncommon and useful.

The material features a regulated grain structure. The common grain dimension falls between 10 and 50 micrometers. This crushed rock type provides a regular base. Users achieve high density after sintering. The density usually goes beyond 3.25 g/cm FIVE. The ceramic generally shows up grey or beige.

Manufacturing choices are versatile. The crushed rock can be shaped using moulding strategies. Usual techniques consist of pressing and casting. These procedures form the initial part shape. Precision machining is additionally possible after that. Machining improves dimensions and develops specific functions. This permits complicated last components.

These homes suit many advanced uses. The ceramic works well in high-power electronics. It assists cool semiconductor devices properly. It works as a substrate for circuits requiring heat dissipation. The material is excellent for laser diode providers. It handles intense warm lots. It additionally functions in vacuum cleaner chambers and various other customized equipment.

(Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining)

Applications of Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining

Gravel aluminum nitride ceramic deals outstanding pureness at 99.99%. This high pureness is critical for demanding technological uses. This ceramic performs warm exceptionally well. It likewise provides excellent electric insulation. These residential properties make it vital for innovative electronic devices. Semiconductor producing relies greatly on it. It develops components for wafer processing equipment. It takes care of extreme heat near silicon wafers. High-power LED producers require this material also. It functions as submounts and warmth spreaders. It pulls heat away from powerful LED chips effectively. This stops overheating and expands LED life. Power electronics profit greatly. It works in modules for electric automobiles and renewable resource systems. It insulates high voltages successfully. It moves warmth away from power semiconductors quick. This enhances gadget reliability and performance. Aerospace and protection applications exist. It fits radar systems and communication gadgets. Its security under extreme problems is useful. It stands up to thermal shock. It keeps toughness at heats. Our item comes as gravel pieces. This form is ready for additional handling. We provide custom-made molding solutions. We shape the ceramic into exact forms for your needs. We additionally supply precision machining. We produce complex parts from strong blocks or pre-sintered forms. Tight resistances are attainable. Surface area finishes meet specific specs.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining

What is Gravel Aluminum Nitride (AlN) Ceramic?

Gravel AlN ceramic is a high-purity material. It comes in small, irregular pieces like gravel. We make it from aluminum nitride powder. This powder is 99.99% pure. The gravel form is ready for further processing.

Why is 99.99% purity important?

Extreme purity is critical for performance. Impurities hurt the material’s abilities. High purity ensures excellent thermal conductivity. It also guarantees strong electrical insulation. This purity makes the ceramic reliable in demanding uses.

Can you shape this AlN gravel?

Yes, we offer moulding and machining services. The gravel can be pressed and sintered into complex shapes. We can also machine sintered AlN blocks precisely. We create parts to your exact drawings and tolerances.

Where is this material typically used?

It’s vital in high-tech electronics and optics. Common uses include semiconductor processing equipment parts. It’s used for laser diode carriers and heat spreaders. It’s also found in high-power LED substrates. Its heat handling and insulation are key.

Can you make custom AlN parts?

Absolutely. We provide full custom manufacturing. Start with our high-purity AlN gravel. We mould it or machine it based on your specifications. We deliver finished components ready for your application. Tell us what you need.

(Gravel Aluminum Nitride Ceramics, 99.99% Purity with Moulding and Machining)

REQUEST A QUOTE

RELATED PRODUCTS

Customize Different Shape Aluminum Nitride Ceramic Parts

AlN Aluminum Nitride Ceramic Plate

High Quality Thermal Conductive AlN Ceramic Aluminum Nitride Plate

High Thermal Conductivity Aluminum Nitride Ceramic Substrate

High Purity Aluminum Nitride Ceramic Sheet