Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules)

Specifications of High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

This Light Weight Aluminum Nitride (Aln) ceramic substrate provides exceptional efficiency for requiring 5G RF and IGBT power components. It uses a very high thermal conductivity of 200W per meter-Kelvin (W/mK). This feature is essential. It moves warmth far from delicate digital parts incredibly quick. Efficient warm transfer prevents getting too hot. Overheating causes device failure.

High electric insulation resistance is an additional crucial strength. This product effectively obstructs unwanted electrical present circulation. Good insulation makes sure trustworthy operation and security. It prevents electric shorts. Electric shorts damage circuits.

The substratum makes use of costs Aluminum Nitride ceramic. AlN ceramic gives excellent thermal monitoring. It additionally supplies strong mechanical buildings. The product is durable. It endures considerable thermal stress. Elements experience repeated heating and cooling cycles. This substrate manages these cycles well. It withstands fracturing.

Its thermal expansion coefficient matches silicon chips closely. This matching is important. It reduces stress at the link factors between the chip and the substrate. Less stress and anxiety suggests fewer failures. Reliability enhances substantially.

This Aln substratum is perfect for high-frequency 5G radio frequency applications. It handles the heat created by effective RF tools. It additionally works completely in IGBT power components. IGBT modules generate substantial warm during changing. Effective warmth removal is vital. This substratum gives that ability.

Its surface area is really smooth. A smooth surface permits accurate circuit pattern. Fine lines and areas are attainable. This precision is needed for contemporary electronics. Production yield boosts. Performance remains consistent.

The product exhibits low dielectric loss. Low loss is essential for RF signals. Signal honesty stays high. Power loss is minimized. This performance is essential for 5G systems.

Using this Aln ceramic substrate boosts power density. Designers can make modules smaller. They can pack even more power into much less room. System dimension and weight reduction. Performance and integrity rise. This technology supports the future generation of power electronic devices.

(High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules)

Applications of High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

Light weight aluminum Nitride ceramic substrates supply one-of-a-kind benefits for demanding electronic devices. Their high thermal conductivity gets to 200W/mK. This moves warm away extremely quickly. Good warm dissipation stops getting too hot. High insulation resistance is one more essential feature. This quits undesirable electrical leaks. These properties make AlN ideal for hard applications.

5G RF modules need top efficiency. High frequencies develop substantial warmth. Efficient air conditioning is essential. AlN substratums manage this warm properly. Keeping parts cool down ensures steady signal transmission. Signal loss is decreased. This boosts 5G base station reliability. The high insulation resistance safeguards sensitive RF circuits. It protects against electrical disturbance. This preserves signal honesty in crowded frequency bands.

IGBT power modules also benefit greatly. These components manage high currents. They create considerable warm throughout operation. Warm build-up problems components and reduces life-span. AlN substratums draw warmth far from IGBT chips effectively. This secures the semiconductor tools. The high insulation resistance is crucial too. It stands up to the high voltages existing in power electronic devices. This stops hazardous short circuits. System safety and security boosts. Power modules last longer and function far better. This is critical for electrical lorries and commercial electric motor drives.

AlN substratums provide a trusted service. They deal with both high warm and high voltage stress and anxiety. This combination is hard to locate. Engineers select AlN for crucial power and RF layouts. It sustains the push for smaller, more powerful electronic devices. Performance requires keep boosting. AlN ceramic helps meet these challenges.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

What makes Aluminum Nitride ceramic special for high-power jobs?

Aluminum Nitride (AlN) ceramic is special. It moves heat away super fast, like 200W per meter per Kelvin. It also blocks electricity incredibly well. This combination is vital for tough jobs. Think 5G radio parts and big power switches (IGBTs). They make a lot of heat and need strong electrical separation. AlN handles both needs perfectly.

Why pick AlN over other ceramics like Alumina?

Alumina is cheaper but much worse at moving heat. It only manages about 25W/mK. AlN moves heat almost ten times faster. This speed is critical. Modern 5G gear and power modules pack huge energy into tiny spaces. They get very hot. Fast heat removal stops parts from failing early. AlN’s high insulation resistance also stops dangerous electrical leaks. This keeps things safe and reliable.

How does the high insulation resistance help?

High insulation resistance means the ceramic strongly resists electricity flowing through it. This is essential. It creates a reliable barrier between different circuit parts. It prevents short circuits. It stops power loss. This barrier stays strong even in demanding conditions. Think high voltages, high temperatures, and humid environments. Good insulation is non-negotiable for safe power electronics.

Is AlN ceramic hard to work with?

No, AlN can be processed well. Manufacturers shape it precisely. They make thin, flat substrates reliably. They can also add metal layers (like copper or aluminum) onto its surface. This creates circuits directly on the ceramic. The process is mature. It delivers parts ready for demanding assembly. You get strong, flat, heat-spreading bases for your chips and components.

Can I get AlN substrates made to my exact needs?

Yes, customization is common. Suppliers offer various sizes and thicknesses. They apply different metal coatings and circuit patterns. Tell them your project’s power level, heat needs, and size limits. They adjust the AlN substrate to match. This ensures the best fit for your specific 5G RF module or IGBT power module design.

(High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminium Nitride Aln Ceramic Substrate Sheet for Electronic

MAX Special Ceramics Material Titanium Aluminum Nitride Ti2AlN Powder

Kerui Aln Ceramics Aluminum Nitride Ceramic for Microwave Equipment Packaging

Aluminum Nitride Aln Insulating Ceramic for Melting

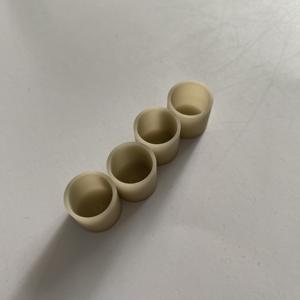

High Thermal Conductivity AlN Aluminum Nitride Ceramic Rings