Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

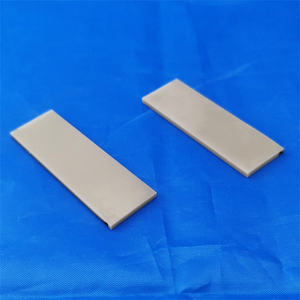

(High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition)

Specifications of High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition

This high-purity aluminum nitride sputtering target delivers 99.5% pure AlN material. It’s designed specifically for thin film deposition processes like sputtering. You need reliable, consistent performance for critical coatings. This target provides exactly that.

The material composition is strictly aluminum nitride. Its purity level minimizes unwanted contaminants in your deposited films. Contaminants cause performance issues. High purity prevents these problems. The target density is very high. High density ensures stable sputtering rates and reduces particle generation during use. Particle generation ruins film quality.

Standard target shapes include discs and rectangles. Common sizes are available. Custom sizes are possible too. The surface finish is precisely controlled. A smooth, flat surface is vital for uniform film deposition. Uniform films mean predictable device performance.

This AlN target creates high-quality aluminum nitride thin films. These films offer excellent thermal conductivity. They also provide strong electrical insulation. These properties are crucial for many advanced applications. The films work well in semiconductor devices. They are essential for LED manufacturing. They function in high-power electronics. They support cutting-edge research too.

Using this sputtering target gives you consistent results. It helps achieve the desired film properties every time. Reliable film properties translate directly to reliable end products. The target material is sintered carefully. This process guarantees structural integrity. Structural integrity means the target lasts longer under intense sputtering conditions. Longer target life saves you money and downtime. It maintains process stability throughout its use.

(High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition)

Applications of High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition

High-purity 99.5% aluminum nitride sputtering targets are essential for creating thin films. These films are vital across many advanced industries. The targets are made from extremely pure aluminum nitride powder. This purity is critical for performance. It ensures the deposited films have excellent properties.

Semiconductor manufacturing is a major application. Companies use these targets to deposit aluminum nitride layers. These layers act as electrical insulators. They prevent unwanted current flow between components. The films also help manage heat effectively in chips. Good thermal management is crucial for device reliability and speed.

The electronics industry relies heavily on these targets. They are key for making surface acoustic wave devices, or SAW filters. These filters are inside smartphones and communication gear. Aluminum nitride thin films are the active piezoelectric material in SAW devices. Their quality directly impacts filter performance. The targets are also used for thin film transistors and other electronic parts needing high-quality insulation.

Optics and protective coatings are another important area. Aluminum nitride films are very hard. They resist wear and scratches extremely well. This makes them perfect for protecting sensitive optical components. Think of lenses or sensors. The films also offer good optical transparency in certain ranges. This is useful for specialized optical applications.

The material’s piezoelectric nature is highly valued. Beyond SAW filters, it enables sensors and micro-electromechanical systems, or MEMS. Devices like pressure sensors or microphones often use aluminum nitride thin films. These films convert mechanical stress into electrical signals efficiently. High purity ensures consistent and reliable piezoelectric response.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition

What is high-purity aluminum nitride?

This material is Aluminum Nitride (AlN). It’s very pure, 99.5% pure. This high purity is critical. It ensures consistent performance during sputtering. Impurities can ruin the thin films made. We guarantee this purity level.

What is this sputtering target used for?

It’s used in machines to deposit thin films. This process is called sputtering. The target is the source material. It makes thin films on things like semiconductors and electronics. These films are essential. They manage heat very well. They also stop electricity effectively. This is vital for high-power electronics and LEDs.

Why choose 99.5% purity AlN?

High purity directly affects the film quality. Higher purity means fewer defects in the film. Films with fewer defects work better. They manage heat superbly. They insulate electricity reliably. Consistency is key for manufacturing. This purity level gives reliable results every time. Lower purity targets cause problems. They lead to unstable film properties.

How should I handle this target?

Handle it carefully. Aluminum nitride is hard but brittle. Avoid impacts or drops. Keep it extremely clean. Even small dirt particles spoil the film. Wear clean gloves. Store it in a dry, clean place. Follow the supplier’s handling instructions exactly. Proper handling prevents damage. It keeps the target ready for use.

Can I get different sizes or shapes?

Yes. We offer customization. Targets come in various sizes. Common shapes are discs or rectangles. We can make other shapes too. Tell us your specific requirements. We need the dimensions you need. We also need details about how it mounts in your machine. We work to meet your exact sputtering setup needs.

(High-Purity 99.5% Aluminum Nitride Sputtering Target for Thin Film Deposition)

REQUEST A QUOTE

RELATED PRODUCTS

High Thermal Conductivity AlN Aluminum Nitride Ceramic Plate

High Thermal Conductivity Aln Aluminum Nitride Ceramic Ring Gaskets

Industry Heat Sink Big Size Aln Substrate Aluminum Nitride Ceramic Plate

Precision Laser Cut Thin Aluminum Nitride Plate Aln Ceramic Substrate

99% High Purity Customized Ain Aluminum Nitride Ceramics Heat Dissipation Solution in The Field of Electronic Packaging