Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

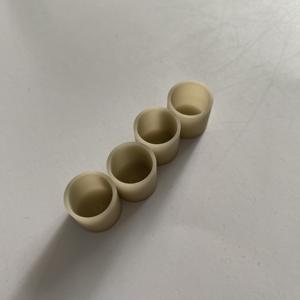

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk)

Specifications of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk

High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk is designed for sophisticated electronics requiring effective warm management. This product provides phenomenal thermal conductivity, normally ranging between 170-200 W/mK. This performance goes beyond traditional alumina ceramics, making it ideal for high-power applications. Its thermal conductivity matches or surpasses some metals while keeping electric insulation. This twin capacity makes certain heat is promptly dissipated without running the risk of short circuits.

The ceramic runs reliably in severe temperature levels, dealing with as much as 1300 ° C in inert environments. It continues to be stable in vacuum conditions and resists thermal shock, stopping cracks throughout quick temperature level adjustments. The material’s chemical resistance is solid versus a lot of corrosive representatives, consisting of acids and antacids. This toughness suits extreme commercial or laboratory setups.

Mechanical strength is robust, with a flexural stamina of 300-400 MPa. The surface finish is smooth, often attaining Ra ≤ 0.4 μm after polishing. Accurate monotony and parallelism are typical, important for applications like semiconductor wafer processing. Customized shapes and sizes are readily available, with sizes from 10 mm to 200 mm and thicknesses from 0.5 mm to 15 mm.

Electric insulation buildings are outstanding, with a quantity resistivity surpassing 10 ¹⁴ Ω · centimeters. This protects against existing leakage even under high voltage. The dielectric constant is low (8-9 at 1 MHz), reducing signal loss in RF parts. Its reduced thermal growth coefficient (4.5 × 10 ⁻⁶/ ° C) very closely matches silicon, reducing stress and anxiety in adhered assemblies.

Applications include warm sinks for LEDs, laser diodes, and power modules. It works as substratums for circuit boards, insulators in high-voltage devices, and providers for semiconductor screening. Metallization alternatives like tungsten or gold plating enable soldering or brazing for safe component assimilation.

The product is without beryllium, making sure safe handling and environmental compliance. Customized finishes or surface therapies enhance performance for particular use instances. Tight resistances are preserved during production, with accuracy grinding ensuring dimensional precision.

This AlN ceramic combines high thermal performance with electrical insulation, mechanical durability, and chemical resistance. It resolves thermal administration challenges in electronics, aerospace, and power systems.

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk)

Applications of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk

Light Weight Aluminum Nitride (AlN) ceramic discs/plates are extensively utilized in markets needing materials that handle warmth effectively. Their high thermal conductivity makes them suitable for digital tools. Warm builds up in circuits and parts throughout procedure. AlN ceramic parts transfer this warm away promptly. This stops overheating and maintains tools stable.

These porcelains work well in high-power LED lights systems. LEDs generate considerable warmth during usage. AlN layers assistance spread out warm evenly. This enhances LED life-span and brightness. The product additionally stands up to deterioration from rough environments.

Power electronic devices like inverters and converters count on AlN discs. High voltage and present create intense heat. AlN’s thermal homes make sure heat is eliminated quickly. This preserves performance and prevents damage. The ceramic’s electric insulation adds safety. It quits undesirable present leaks.

Semiconductor production utilizes AlN plates for wafer handling. High temperatures are common in manufacturing phases. AlN handles extreme heat without breaking down. It additionally matches silicon’s development rate. This decreases stress throughout heating cycles.

AlN ceramics fit superhigh frequency (RF) and microwave gadgets. These components require materials that dissipate warm and shield electrically. AlN does both. Signal loss remains reduced even at high frequencies. This makes communication systems trusted.

Aerospace and vehicle industries use AlN for thermal monitoring. Electric vehicles and aircraft require reliable cooling options. AlN parts handle heat in batteries and power systems. They stand up to resonance and thermal shock. Longevity in challenging problems is vital right here.

AlN’s chemical stability allows use in corrosive setups. Industrial sensors and activators often deal with acids or gases. The product stands up to erosion and maintains efficiency in time.

Aluminum Nitride porcelains balance thermal conductivity with electrical insulation. This combination is rare in other materials. Their convenience sustains advanced innovations throughout areas. Demand grows as sectors seek far better heat monitoring options.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk

High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk FAQs

What is aluminum nitride ceramic used for? Aluminum nitride ceramic moves heat efficiently. It works in electronics needing heat control. Common uses include LED lighting, semiconductor parts, power modules. It insulates electricity while moving heat away. This stops devices from overheating.

Why pick aluminum nitride over other ceramics? Aluminum nitride moves heat better than alumina or aluminum. It transfers heat 10 times faster than alumina. It handles high temperatures without breaking. It resists chemicals. It is good for harsh environments. These traits make it ideal for advanced tech applications.

Is aluminum nitride ceramic safe to handle? Aluminum nitride is safe under normal conditions. Avoid breathing dust during machining. Use protective gear like masks. The material is non-toxic once polished. Handle it carefully. It is brittle. Dropping or hitting it can cause cracks.

Can aluminum nitride ceramic replace metal heat sinks? Aluminum nitride works better than metal in some cases. Metals conduct heat well but electricity too. Aluminum nitride insulates electricity. This prevents short circuits. It suits high-power electronics where insulation matters. Metal sinks need extra insulation layers. Aluminum nitride simplifies designs.

How does surface finish affect performance? Smooth surfaces improve heat transfer. Rough surfaces trap air. Air reduces contact between parts. This lowers heat movement. Polishing ensures full contact. Machining marks or dirt block efficiency. Clean surfaces with isopropyl alcohol. Proper finishing ensures maximum thermal performance.

(High Thermal Conductivity AlN Aluminum Nitride Electrical Ceramic Disc/Plate/Disk)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Supply High Purity Ceramic Microspheres Spherical Aln Powder Spherical Aluminum Nitride Powder Used in Industry Aluminum Nitride for Ceramic

Active Metal Brazing Amb Copper Coated Aluminum Nitride Ceramic Sheet Aln Substrate

Excellent Thermal Conductivity Aluminium Nitride AlN Ceramic Substrate

Composite Boron Nitride+Aluminum Nitride Bn/Aln Ceramics

Factory AlN Ceramic Products Aluminum Nitride Powder AlN Ceramic