Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

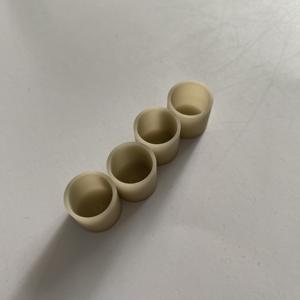

(High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate)

Specifications of High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate

Aluminum Nitride ceramic plates provide outstanding thermal performance. This material relocates heat very well. Common thermal conductivity worths reach 170 to 200 W/mK. This high conductivity makes these plates perfect for requiring electronics. Heat escapes quickly from hot elements. Gadgets remain cooler and operate even more reliably.

Electrical insulation is an additional important feature. Light weight aluminum Nitride is a strong electrical insulator. Its quantity resistivity is extremely high, commonly going beyond 10 ^ 14 Ω · centimeters. This stops electric existing leak. Circuits remain risk-free and perform appropriately. You get exceptional seclusion between parts.

Thermal expansion matching is essential. Light weight aluminum Nitride’s thermal expansion coefficient closely matches silicon. The values are really comparable. This lowers tension throughout heating and cooling down cycles. Silicon chips bond firmly to the substratum. Splitting and link failures become a lot less most likely.

Mechanical strength is very important also. These ceramic plates are extremely hard and inflexible. They stand up to bending and damaging. The product takes care of considerable physical tension. It also holds up against harsh processing conditions. This toughness guarantees long-lasting reliability in difficult settings.

Surface area top quality matters for production. The plates include a really smooth, level surface. Precision sprucing up attains this fine finish. Slim movies and circuit patterns deposit precisely. Excellent bonding happens dependably. Issues are decreased.

High pureness ensures regular performance. Suppliers make use of extremely pure basic materials. Light weight aluminum oxide pollutant degrees are kept low, generally under 5%. This pureness straight impacts thermal conductivity. It additionally influences electrical insulation residential properties. Consistency batch-to-batch is ensured.

Various production techniques exist. Common techniques include tape casting and isostatic pushing. Each approach fits specific plate sizes and thicknesses. The chosen process influences the final microstructure. This influences vital buildings like thermal conductivity and strength.

(High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate)

Applications of High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate

Aluminum Nitride ceramic plates relocate heat extremely well. This residential or commercial property makes them vital throughout requiring markets. Electronics require reputable air conditioning remedies. AlN substrates spread out heat fast far from sensitive chips. This prevents getting too hot. It likewise enhances the tool’s total efficiency and lifespan. LED suppliers count heavily on these substrates. High-power LEDs generate substantial warm. AlN plates successfully attract this heat off the LED chips. This maintains the lights brighter much longer. It avoids early failure. Power electronic devices deal with big currents. Think electric cars and industrial power products. AlN is ideal for protecting and cooling down power components. It safely isolates high voltage components. It simultaneously relocates warm to the warm sink. This dual function is critical. Semiconductor making uses extreme procedures. AlN plates serve reliably in these harsh settings. They develop components inside high-temperature furnaces and plasma etching chambers. Their stability under heat and chemical exposure is vital. AlN ceramic plates are not simply warmth spreaders. They are fundamental enablers for innovative technology needing premium thermal control and electric insulation. Their duty is expanding in power electronic devices, advanced illumination, and microelectronics.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate

These AlN ceramic plates move heat exceptionally well. People often ask why choose them over other materials. Aluminum nitride conducts heat far better than regular alumina ceramics. This makes AlN plates perfect for electronics needing serious cooling. Heat spreads quickly and evenly across the whole plate surface. This keeps sensitive electronic parts much cooler. Cooler parts last longer and work better.

Another common question is about electrical insulation. AlN plates are excellent electrical insulators. They stop electricity flowing through them. This is vital in electronic circuits. You can place them directly under hot components. The heat escapes fast, but electricity stays contained. Safety and performance both improve.

People wonder how hot these plates can get. AlN ceramic handles very high temperatures easily. It stays stable and strong well over 1000 degrees Celsius. Its properties don’t weaken significantly under heat stress. This reliability is key in demanding applications like power electronics. The plate won’t fail when things get hot.

Handling concerns come up too. Are these plates fragile? Like most ceramics, AlN can chip or crack if dropped or hit hard. You need reasonable care during assembly and use. Avoid sharp impacts or excessive bending force. Normal handling for electronic assembly is usually fine. Just treat them with basic caution.

Finally, folks ask where these plates get used. They are crucial in high-power electronics. Think LED lighting systems generating lots of heat. Power converters and modules in electric vehicles need them. Semiconductor laser packages rely on AlN. Any device pushing serious power needs efficient heat removal. AlN plates deliver that thermal performance reliably.

(High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Premium Ceramics Product Ultrathin High Temperature Polished Aln Aluminum Nitride Ceramic Substrate Sheet

ALN-BN ceramics boron nitride composite ceramics

High Insulation Resistance 200W/Mk Thermal Conductivity Aluminum Nitride Aln Ceramic Substrate for 5g RF & IGBT Power Modules

Heat Dissipation Aluminum Nitride Substrate Aln Ceramic Plate for PCB

High Precision Aln Aluminum Nitride Ceramic Tube Rod