Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

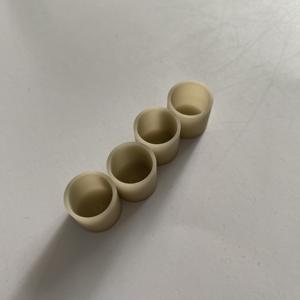

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

Specifications of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

Market electric CNC machining ceramic components made from light weight aluminum nitride ceramic (ALN) provide high-performance heat dissipation options for CPU and LED applications. These components deal with extreme thermal conditions effectively. The material’s key function is high thermal conductivity. ALN ceramic conducts warmth quite possibly. It transfers warm far from delicate electronic components fast. This avoids overheating. It maintains stable procedure in high-power gadgets. The thermal conductivity of ALN ceramic ranges between 170-220 W/mK. This outperforms several typical metals and porcelains.

Electrical insulation is one more essential residential property. ALN ceramic does not conduct electrical power. It separates electronic components safely. This lowers short-circuit dangers. It sustains usage in high-voltage environments. The product’s thermal expansion coefficient matches silicon. This guarantees compatibility with semiconductor materials. It lessens tension throughout temperature changes.

These warm sinks are manufactured making use of precision CNC machining. This enables limited resistances. Facility shapes and great information are attainable. Surface area coatings are smooth. Roughness levels stay below 0.4 micrometers. This boosts contact with warmth sources. It maximizes warmth transfer performance.

Aluminum nitride ceramic resists chemical deterioration. It operates in harsh environments. Exposure to acids, antacid, or moisture does not degrade it. Running temperature levels reach up to 1800 ° C. It remains stable under extreme warm. Mechanical toughness is high. ALN ceramic withstands physical anxiety without splitting.

Modification choices consist of differing sizes, densities, and geometries. Layouts match specific gadget needs. Applications include CPU cooling in computer systems, LED thermal management in illumination systems, and power electronics in commercial equipment. Quality assurance complies with worldwide standards. Each component undergoes rigorous testing. Criteria like dimensional precision and thermal efficiency are verified.

The combination of sophisticated material residential or commercial properties and accuracy machining makes ALN ceramic warmth sinks reputable. They prolong the life expectancy of electronic components. They guarantee consistent performance under demanding problems.

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

Applications of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

Market electric CNC machining ceramic components made from aluminum nitride (ALN) are necessary for advanced thermal management in high-performance electronic devices. Light weight aluminum nitride ceramic stands out due to its high thermal conductivity. It successfully moves warm far from delicate elements. This makes ALN warmth sinks ideal for CPUs and LEDs. These gadgets generate significant heat throughout procedure. Correct heat dissipation makes certain steady performance and extends lifespan.

ALN ceramic withstands electric current. It functions as an insulator while relocating warmth. This dual function is vital in electronics. Traditional steels like aluminum conduct heat well yet do not have insulation. ALN resolves this trouble. It combines thermal conductivity with electrical isolation. Makers make use of CNC machining to shape ALN right into specific warmth sink layouts. CNC technology makes sure limited tolerances and smooth surface areas. This enhances call in between the warmth sink and the part. Better call makes best use of heat transfer.

In CPU applications, ALN warm sinks avoid getting too hot in processors. Overheating reasons strangling or failure. Efficient cooling maintains computing speed and dependability. For LEDs, excess warm breaks down light result and long life. ALN warmth sinks maintain temperatures stable. This protects brightness and minimizes upkeep expenses.

The product also stands up to severe settings. It withstands rust, wear, and high temperatures. ALN parts stay secure under thermal cycling. This sturdiness matches commercial devices, auto systems, and aerospace innovation. CNC-machined ALN parts are customizable. Engineers change forms, dimensions, and mounting functions to fit details tools.

Light weight aluminum nitride ceramics are costlier than common products. The advantages warrant the financial investment in demanding applications. Minimized downtime, higher effectiveness, and longer device life offset first expenses. Industries prioritize reliability and performance. ALN heat sinks fulfill these requirements.

CNC machining guarantees consistency in mass production. Automated processes minimize human mistake. Each part matches exact requirements. This accuracy is vital for high-tech applications. ALN’s homes and progressed manufacturing make it a top option for modern thermal solutions.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED

What is Aluminum Nitride Ceramic (ALN)? Aluminum Nitride Ceramic is a material with high thermal conductivity. It works well for moving heat away from electronic parts. It also acts as an electrical insulator. This stops unwanted currents. ALN is used in places needing both heat control and electrical safety.

Why use ALN for CPU and LED heat sinks? ALN moves heat faster than many metals or plastics. CPUs and LEDs create a lot of heat during use. Overheating damages performance. ALN heat sinks keep temperatures stable. They handle high-power setups better than traditional materials.

How does CNC machining improve ALN ceramic parts? CNC machines shape ALN with high precision. Complex designs are possible. Tight tolerances ensure parts fit perfectly in devices. Smooth surfaces from machining help contact with heat sources. This boosts heat transfer efficiency.

What applications use ALN ceramic heat sinks? ALN heat sinks are common in electronics needing heat control. Examples include computer processors, LED lighting systems, telecom equipment, and electric vehicle parts. High-power industrial tools and medical devices also use them.

How to maintain ALN ceramic heat sinks? Clean them regularly with non-abrasive cloths. Avoid strong chemicals. Check for cracks or chips. ALN is durable but physical damage lowers performance. Ensure proper installation to prevent stress on the material. Store in dry conditions to avoid moisture buildup.

(Industry Electrical CNC Machining Ceramic Parts Aluminum Nitride Ceramic ALN Heat Sink for CPU LED)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity AlN Aluminium Nitride AlN Ceramic Rod Tube Bushing for Structure Ceramic Customizable Cutting

High Temperature Ceramic Tubular Dry Press Aluminum Nitride Bush Bushing Rod

Electrical Insulation Thermal Conductivity Aln Aluminum Nitride Ceramic Substrate Sheet Disc Chip

Affordable Aluminum Nitride Block Functional Ceramics for Aluminum Ceramics

High Purity Aluminum Nitride Ceramic ALN Granule 70-120um 99.95%