Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

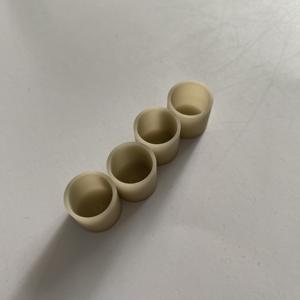

Overview of Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel)

Specifications of Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel

Crushed rock creates costs 99.99% Aluminum Nitride (AlN) ceramics. We use innovative moulding and accuracy machining. This guarantees top-notch components. The product offers exceptional thermal conductivity. It relocates warm quick. This is vital for high-power electronic devices. Warmth buildup creates failings. AlN avoids this efficiently.

The material provides strong electrical insulation. It stops current circulation dependably. This makes certain security in circuits. High voltage applications require this. AlN supplies regularly. The ceramic has excellent mechanical stamina. It withstands damaging under stress. Parts last much longer this way. Handling is safer as well.

Thermal expansion matters. AlN matches silicon closely. Silicon is common in electronics. Various expansion rates cause tension. Splits or failures take place. AlN reduces this issue. It works well with silicon chips. Performance remains secure gradually.

Our process utilizes moulding first. We form the standard form exactly. Then we apply mindful machining. This attains tight tolerances. Complex attributes become feasible. Smooth surface areas result. Fit and feature enhance significantly. We satisfy demanding specifications easily.

Gravel’s AlN ceramics offer lots of markets. Electronic devices rely on them for heat spreaders. Substratums for circuits use AlN. Semiconductor equipment requires these parts. Laser systems benefit substantially. Industrial tools use them. Any kind of application needing warm control and electrical seclusion takes into consideration AlN.

(Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel)

Applications of Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel

Premium 99.99% Aluminum Nitride ceramics from Crushed rock deal leading performance. Individuals utilize them popular situations requiring exceptional heat control and electrical seclusion. Crushed rock makes these porcelains using sophisticated molding and precision machining. This process develops facility, dependable components.

Electronics makers depend on this material. It moves warm away from delicate elements very well. This protects against overheating and failure. Light weight aluminum Nitride substratums and warm sinks are common. They keep power electronic devices, LED lights, and high-power circuits awesome and stable. The material shields electrically as well. This is important for security and function.

The semiconductor market utilizes Crushed rock’s Light weight aluminum Nitride components heavily. It manages the intense heat inside chip-making equipments. Elements like wafer chucks and procedure chamber components need its security. Aluminum Nitride withstands corrosion from harsh chemicals used in chip manufacturing. This guarantees lengthy life and constant results.

High-power lasers also depend on this ceramic. Laser diodes create considerable warm. Light weight aluminum Nitride real estates and warm spreaders manage this heat effectively. They stop laser power loss and damage. The material’s stability keeps the laser beam of light focused and strong.

Gravel’s molding and machining procedure is a big benefit. Molding creates near-net-shape parts. Accuracy machining then completes them to specific sizes and smooth surface areas. This is essential for parts fitting completely into assemblies. It ensures the best thermal get in touch with and electrical seclusion. Complex geometries are feasible. This adaptability fulfills specific style requirements.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel

Premium 99.99% Aluminum Nitride Ceramics: Moulding Plus Machining by Gravel – FAQs

What is this Aluminum Nitride?

This is a very pure ceramic material. Gravel makes it using 99.99% pure aluminum nitride powder. This high purity makes it perform very well.

Why use Aluminum Nitride?

Its main benefit is moving heat away quickly. It works much better than most other ceramics for this. It also resists electricity well. It doesn’t expand much when heated. These properties are good for electronics needing cooling.

Can Gravel make custom shapes?

Yes. Gravel uses moulding and machining together. They form the basic shape first. Then they machine it precisely. This method gives complex shapes and tight tolerances. It saves time and material.

What size parts can Gravel make?

Gravel handles various sizes. Their moulding and machining work for both small and large parts. They can make parts a few millimeters big. They can also make parts over 100 millimeters big. Ask them for your specific size.

How smooth is the surface?

The surface finish depends on the machining step. Gravel can achieve very smooth surfaces. This is important for many uses. They control the surface roughness carefully. Tell them your smoothness requirement. They will meet it.

(Premium 99.99% Aluminum Nitride Ceramics, Moulding Plus Machining by Gravel)

REQUEST A QUOTE

RELATED PRODUCTS

ALN-BN ceramics boron nitride composite ceramics

Factory Supply Aln Powder Aluminum Nitride Powder with Low

Whole Cheap ALN Ceramic Board Aluminium Nitride Ceramic Part Structural Parts

Aln/Aluminum Nitride Ceramics Substrate and Plate

Good Insulation Aluminium Nitride Copper-Coated Ceramic Sheet ALN Metallized Substrate