Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

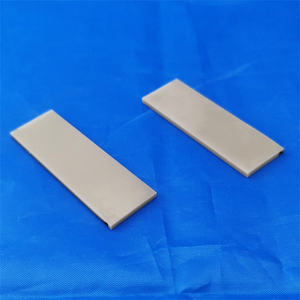

(Round AlN Aluminum Nitride Ceramic Plate)

Specifications of Round AlN Aluminum Nitride Ceramic Plate

The Round AlN Aluminum Nitride Ceramic Plate is designed for high-performance applications requiring thermal management and electrical insulation. This product uses aluminum nitride ceramic, a material known for combining high thermal conductivity with strong electrical resistance. The plate suits environments where heat dissipation and insulation are critical.

The standard diameter of the plate ranges from 10mm to 150mm. Thickness options vary between 0.5mm and 5mm. Custom sizes are available for specific needs. The round shape ensures even heat distribution and compatibility with standard industrial setups.

Thermal conductivity reaches 170-200 W/mK, making it effective for transferring heat away from sensitive components. The material operates reliably in temperatures up to 1300°C in inert atmospheres. It withstands thermal cycling without cracking or warping.

Electrical insulation properties are strong. The dielectric strength exceeds 15 kV/mm. Volume resistivity stays above 10^14 Ω·cm even at high temperatures. This prevents current leakage in electronic devices.

Chemical resistance is high. The plate resists corrosion from acids, alkalis, and molten metals. It performs well in harsh industrial conditions without degrading.

Surface finishes include polished and unpolished options. Polished surfaces reduce friction and improve contact with heat sinks. Unpolished surfaces are cost-effective for general use. Dimensional tolerances are tight. Diameter tolerance is ±0.1mm. Thickness tolerance is ±0.05mm. This precision ensures consistent performance in assembly processes.

Applications cover electronics, LED lighting, semiconductor manufacturing, and power modules. The plate acts as a heat sink substrate, circuit carrier, or insulating layer. It is used in high-power LEDs, laser diodes, and RF modules. Compatibility with thin-film metallization allows integration into custom electronic designs.

The Round AlN Ceramic Plate meets demands for durability, efficiency, and adaptability. It serves industries prioritizing thermal control and electrical safety. Customization options address specialized requirements.

(Round AlN Aluminum Nitride Ceramic Plate)

Applications of Round AlN Aluminum Nitride Ceramic Plate

Round AlN aluminum nitride ceramic plates are widely used in industries requiring high thermal conductivity and electrical insulation. These plates handle extreme temperatures and harsh conditions. They work well in electronics for managing heat in power modules, LED lighting, and semiconductor devices. The material moves heat away from sensitive parts, improving performance and lifespan.

In the automotive sector, these plates cool electric vehicle components like battery systems, inverters, and onboard chargers. They prevent overheating, ensuring reliability and safety. Their resistance to thermal shock suits them for fast temperature changes common in electric cars.

Industrial equipment uses these plates in high-temperature settings such as furnaces, reactors, and heat treatment tools. They protect machinery from damage caused by heat buildup. Their chemical stability makes them ideal for corrosive environments.

Aerospace applications rely on the plates for thermal control in communication systems, radar units, and power electronics. They perform under vibration, radiation, and temperature shifts. Their lightweight nature helps reduce overall system weight.

Medical devices use AlN ceramic plates in imaging systems, laser components, and surgical tools. They stay stable during sterilization and resist wear. Their non-toxic properties make them safe for medical environments.

The material’s high thermal conductivity matches metals like aluminum but with better insulation. It expands minimally under heat, avoiding cracks or warping. This durability suits long-term use in demanding settings.

Round AlN plates are machined into custom shapes for specific needs. They fit tightly into assemblies, ensuring efficient heat transfer. Surface treatments or coatings enhance their performance for specialized tasks.

These plates are chosen for their ability to combine heat management, electrical insulation, and mechanical strength. They address challenges in advanced technology and industrial systems. Their versatility supports innovation across fields needing reliable thermal solutions.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Round AlN Aluminum Nitride Ceramic Plate

What is Round AlN Aluminum Nitride Ceramic Plate used for? Round AlN plates handle high heat in electronics. They move heat away from parts like LEDs, power modules, or semiconductor devices. The material insulates electricity, so it stops short circuits. This makes them good for heat sinks, circuit boards, and industrial tools needing temperature control.

How does aluminum nitride compare to alumina or beryllia ceramics? Aluminum nitride moves heat better than alumina. It works almost like beryllia but is safer. Beryllia is toxic when machined. AlN avoids this risk. It still keeps strong electrical insulation and resists chemical damage.

What temperatures can Round AlN Ceramic Plates handle? These plates work from -40°C to over 1200°C. They stay stable in extreme heat. This suits furnaces, laser systems, or high-power electronics. The material doesn’t crack easily under rapid temperature changes.

Are there handling precautions for AlN plates? AlN is brittle. Avoid dropping or hitting the plates. Use gloves to prevent oil from skin affecting performance. Clean surfaces with alcohol or mild soap. Don’t use rough scrubbers. Store plates separately to prevent scratches.

Can Round AlN Plates be customized? Yes. Sizes and thicknesses vary based on needs. Holes, grooves, or coatings like metallization are added for specific uses. Custom shapes take longer but are possible. Most suppliers offer samples to test before bulk orders.

(Round AlN Aluminum Nitride Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High thermal conductivity thick film aln aluminum nitride ceramic pcb and alumina pcb substrate

220V 380V Aluminum Nitride Ceramic Sheet AlN Heating Element Heater Plates

180W/mk High Thermal Conductivity Aluminum Nitride Ceramic Pad AIN ALN Ceramic Sheet for IC MOS Tube/IGBT Chip

High Quality 99.9% Aluminum Nitride Powder AlN Powder for Ceramics and Semiconductor CAS 24304-00-5

High Quality Aluminum Nitride Aln CAS 24304-00-5 for Industry