Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Titanium Aluminum Nitride Coating Machine for Tools

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of Titanium Aluminum Nitride Coating Machine for Tools

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Titanium Aluminum Nitride Coating Machine for Tools)

Specifications of Titanium Aluminum Nitride Coating Machine for Tools

This Titanium Aluminum Nitride coating machine applies hard coatings onto tools. It uses PVD technology. This means the coating forms physically, not chemically. The process happens inside a vacuum chamber. This keeps things very clean. The machine heats tools to medium temperatures. This temperature suits many tool steels. It prevents damage to the tools.

The machine controls the coating process precisely. It manages power levels, gas flows, and pressure carefully. This control ensures the coating quality stays consistent. You get the same results every time. The TiAlN coating is very hard. It protects tools from wear. The coating also handles high heat well. Tools last much longer.

The machine prepares tool surfaces first. It cleans them thoroughly. This cleaning step is vital. The coating sticks better to a clean surface. Strong adhesion means the coating won’t flake off easily. The machine can coat batches of tools. Batch sizes vary depending on the machine model. This makes it efficient for different production levels.

Different coating thicknesses are possible. You choose the thickness needed for your tools. Thicker coatings offer more protection. Thinner coatings keep sharp edges better. The machine runs reliably. It needs regular maintenance. This maintenance keeps performance high. Operating the machine requires training. Staff learn the procedures safely. The coating process is environmentally sound. It uses no harmful chemicals. Waste is minimal. This machine upgrades tool performance significantly. It boosts productivity and lowers tool replacement costs.

(Titanium Aluminum Nitride Coating Machine for Tools)

Applications of Titanium Aluminum Nitride Coating Machine for Tools

Titanium Aluminum Nitride coating machines put a super hard layer on cutting tools. This layer is called TiAlN. It makes tools last much longer. Tools wear out slower. This saves money. You don’t need to replace tools as often.

These machines coat tools using a special vacuum process. The process is called Physical Vapor Deposition, or PVD. The machine heats titanium and aluminum metals inside a vacuum chamber. It turns them into a vapor. This vapor sticks to the tools. It forms a very thin, very tough coating.

The TiAlN coating is great for heat. It handles high temperatures really well. Tools stay sharper longer when they get hot. This is important for fast cutting. The coating also fights friction. Tools slide easier against the material being cut. This reduces the power needed. It gives a better finish on the workpiece.

Coated tools cut harder materials easier. Steel, stainless steel, and tough alloys are no problem. The coating protects the tool edge. It stops the tool material from reacting with the workpiece. This prevents built-up edge. Machining accuracy improves. Surface finish gets better too.

Many industries use these coated tools. Metal cutting shops see big benefits. Aerospace manufacturers need tough tools for exotic alloys. Automotive plants use them for high-volume production. Even woodworking tools get coated. The coating fights resin buildup. Tool life extends significantly everywhere.

The coating machine itself is reliable. Modern units are automated. They coat many tools at once. Running costs are reasonable. The long tool life pays for the coating quickly. It’s a smart upgrade for any serious machining operation.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Titanium Aluminum Nitride Coating Machine for Tools

Customers often ask these questions about Titanium Aluminum Nitride (TiAlN) coating machines. Knowing the answers helps you understand their value.

What exactly is TiAlN coating? TiAlN is a super hard ceramic layer applied to tools. The machine uses a method called PVD. This stands for Physical Vapor Deposition. It puts an incredibly thin, strong film on the tool surface. This coating is gold in color.

Why coat tools with TiAlN? The coating dramatically improves tool life. It makes cutting tools much more resistant to wear. Tools resist heat better. They resist friction better. The coating reduces sticking. This means tools last longer. You get more parts made per tool. Production costs go down.

How long does the TiAlN coating last? The coating life depends heavily on the tool’s use. Cutting conditions matter a lot. The material being cut matters. Generally, TiAlN coatings last many times longer than uncoated tools. Proper use extends the coating life significantly. The coating itself is extremely durable.

What kinds of tools get TiAlN coated? Many cutting tools benefit greatly. End mills are common. Drills are common. Inserts are common. Reamers are common. Any tool facing high heat or wear is a good candidate. TiAlN excels on tools for tough materials like steel or stainless steel.

How does the coating machine work? Tools are cleaned thoroughly first. They go into a special vacuum chamber. The machine heats the chamber. It creates a plasma environment. Titanium and aluminum atoms are released. They react with nitrogen gas. This forms the TiAlN coating. It bonds strongly to the tool surface. The process is tightly controlled. This ensures a consistent, high-quality coating every time.

(Titanium Aluminum Nitride Coating Machine for Tools)

REQUEST A QUOTE

RELATED PRODUCTS

Insulator Electronic Device Aln Aluminum Nitride Ceramic Tube Pipe

Aluminum Nitride Ceramic Disc AlN Substrate

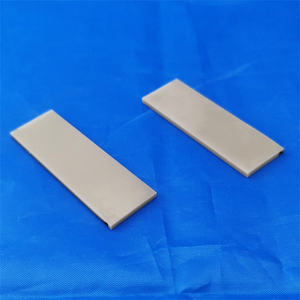

High Thermal Conductivity Aln Ceramic Plate Aluminum Nitride Substrate for Power Electronics

ALN Aluminum Nitride ALN Ceramic Tube

Ceramic Insulating Aln Aluminum Nitride Sleeve