Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of aluminum nitride ceramics

Aluminum Nitride Ceramic is an advanced ceramic material with aluminum nitride as the main component. It has been widely used in electronics, optics, and mechanics due to its unique properties.

Features of aluminum nitride ceramics

High thermal conductivity: Aluminum nitride ceramics have relatively high thermal conductivity, usually between 170-260 W/m·K, which makes it an excellent heat dissipation material. It is especially suitable for electronic devices that require efficient heat dissipation, such as substrate materials for power semiconductor devices.

Good electrical insulation: Despite its high thermal conductivity, aluminum nitride ceramics are excellent insulators of electricity, which can effectively prevent current leakage and ensure the safe operation of electronic components.

Low dielectric constant and dielectric loss: These characteristics make aluminum nitride ceramics very suitable for use in high-frequency circuits because it can reduce energy loss during signal transmission.

High temperature resistance: Aluminum nitride ceramics can maintain structural stability and strength at extremely high temperatures. Its melting point is about 2800°C, so it is suitable for applications in high temperature environments.

Low thermal expansion coefficient: Compared with semiconductor materials such as silicon, aluminum nitride has a lower thermal expansion coefficient, which means it has better dimensional stability when the temperature changes, which helps improve packaging reliability.

Corrosion resistance: Aluminum nitride ceramics have good chemical stability to most molten metals and are not easily oxidized or corroded, allowing them to perform well in harsh environments.

High mechanical strength: Although not as hard as some other types of ceramic materials, aluminum nitride ceramics still provide enough mechanical strength to allow them to be used in many structural applications.

(Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator)

Specifications of Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator

The Wear Resistance Insulation ALN Light Weight Aluminum Nitride Ceramic Ring/Spacer/Insulator serves critical roles in high-performance industrial and digital setups. Made from advanced light weight aluminum nitride ceramic, this component combines high thermal conductivity with superb electrical insulation. It manages severe temperature levels, stands up to wear, and preserves security under harsh conditions.

Aluminum nitride ceramic stands out for its thermal residential properties. It moves warmth successfully, making it excellent for applications requiring heat dissipation. Its electrical insulation protects against present leak, making certain safety in electronic devices. The product stands up to chemical rust and mechanical wear, extending life span sought after environments.

These ceramic rings, spacers, and insulators match multiple markets. They operate in power electronics, semiconductor production, LED lighting, and laser systems. Their capability to endure temperature levels up to 1800 ° C makes them reputable in furnaces, aerospace parts, and auto systems. Accuracy machining guarantees limited tolerances, suitable seamlessly into complex settings up.

Secret requirements consist of a thermal conductivity of 170-200 W/m · K, outshining lots of typical ceramics. Operating temperature levels range from -40 ° C to 1800 ° C. The material’s electrical resistivity exceeds 10 ^ 14 Ω · cm, preventing conductivity under high voltage. Firmness steps 12-14 Grade point average (Vickers), making sure resistance to abrasion. Density remains around 3.26 g/cm ³, balancing stamina with lightweight layout.

Custom shapes and sizes are available. Criterion measurements vary from 1 mm to 200 mm in outer diameter, with densities from 0.5 mm to 50 mm. Surface area surfaces can be polished or coated for certain applications. The ceramic is non-reactive, ideal for vacuum cleaner settings and cleanroom usage.

These parts decrease downtime in equipment by lessening wear-related failings. They boost warm management in small digital tools, improving performance and long life. Compatibility with steels and various other materials enables versatile combination.

The ALN ceramic rings, spacers, and insulators fulfill stringent sector criteria for high quality and reliability. They are checked for thermal shock resistance, mechanical strength, and dielectric residential or commercial properties. Producers supply accreditations upon demand, making certain conformity with technical demands.

Customization choices include threaded holes, grooves, and special geometries. Bulk orders are sustained for large-scale tasks. Preparations differ based upon style intricacy, with typical products frequently offered for immediate shipment.

(Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator)

Applications of Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator

Aluminum Nitride (ALN) ceramic rings, spacers, and insulators are high-performance products used in markets calling for sturdiness and thermal monitoring. Their wear resistance makes them excellent for mechanical systems revealed to rubbing. These components manage severe temperature levels, keeping stability in environments varying from -200 ° C to 1800 ° C. This home fits them for aerospace applications, such as engine components or satellite systems.

In electronic devices, ALN porcelains avoid electric leakage while conducting warmth efficiently. Semiconductor manufacturing uses ALN spacers to separate delicate components from warmth damages. Power components in electrical vehicles count on ALN insulators to manage heat from high-voltage systems. This improves gadget dependability and prolongs service life.

LED lights systems take advantage of ALN ceramic rings. They dissipate warmth produced by high-power LEDs, stopping getting too hot and color shifts. Laser diodes in clinical or commercial devices use ALN components for comparable reasons. The material’s insulation residential properties ensure risk-free operation in portable, high-energy setups.

Industrial machinery uses ALN porcelains as wear-resistant components in pumps, shutoffs, and bearings. Their hardness minimizes erosion in rough atmospheres, lowering maintenance expenses. Chemical processing equipment utilizes ALN spacers to resist corrosion from acids or antacid. This guarantees lasting performance in harsh problems.

Renewable energy systems, like photovoltaic panels or wind turbines, incorporate ALN insulators to take care of electric stress and anxiety and thermal cycling. Their security under temperature changes avoids splits or failings. Electric car battery packs usage ALN parts to isolate cells and take care of heat, enhancing security and effectiveness.

Clinical tools utilize ALN ceramics for imaging equipment or surgical tools. The product’s safe nature and resistance to sterilization procedures make it ideal for duplicated usage. ALN’s electrical insulation additionally avoids disturbance in sensitive analysis tools.

Automotive sensing units and ignition systems rely upon ALN components to endure engine warm and vibration. This ensures precise analyses and constant performance. ALN porcelains are likewise utilized in 3D printing nozzles, where high wear resistance and thermal conductivity protect against clogging during extended usage.

The convenience of ALN ceramics comes from their special mix of insulation, thermal administration, and mechanical stamina. These properties resolve obstacles in innovative manufacturing, power, and innovation sectors.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator

What makes aluminum nitride ceramic rings stand out? Aluminum nitride ceramic rings offer high thermal conductivity and excellent electrical insulation. They handle extreme temperatures and resist wear effectively. Their stability in harsh environments makes them reliable for demanding applications. This material is also lightweight compared to metals.

How does aluminum nitride’s thermal conductivity help? Aluminum nitride conducts heat 10 times better than alumina ceramics. This property prevents overheating in electronic and mechanical systems. Heat transfers quickly away from sensitive components. This keeps devices running efficiently. It is ideal for heat sinks, power modules, and LED systems.

Where are these ceramic spacers commonly used? These parts are used in electronics, automotive systems, and industrial machinery. They serve as insulators in circuit boards, engine sensors, and semiconductor equipment. High-temperature furnaces and laser systems also use them. Their durability suits heavy-duty environments.

Why is wear resistance important for these insulators? Wear resistance ensures long service life under friction or mechanical stress. Aluminum nitride’s hardness prevents surface damage from abrasion. This reduces maintenance needs and replacement costs. It performs well in moving parts like bearings or seals.

Can these ceramic rings be customized? Yes. Manufacturers adjust sizes, shapes, and thicknesses to fit specific needs. Surface coatings or metallization can be added for better bonding. Custom designs require detailed specifications. Samples are often tested to confirm performance.

(Wear Resistance Insulation ALN Aluminum Nitride Ceramic Ring/ Spacer/Insulator)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Insulation High Temperature Aln Aluminum Nitride Rod Roller Shaft Cylinder

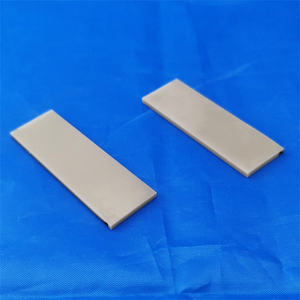

ALN High Thermal Conductivity Aluminum Nitride Ceramic Block

Custom Shape ALN Aluminum Nitride ALN Ceramic Seal Ring

Excellent Heatsink Performance Aln Plate Aluminum Nitride Ceramic Substrate

High Quality Aluminum Nitride Aln CAS 24304-00-5 for Industry