Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to 125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide

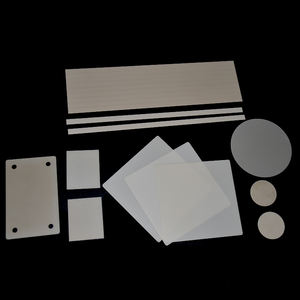

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of 125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide)

Specifications of 125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide

These 125mm sanding discs are produced auto body job. They use light weight aluminum oxide grit. The grit bonds strongly to a material backing. The backing is an unique mesh material. This mesh style is key. It allows dust go through quickly. Less dirt accumulation happens. This keeps the disc cutting longer. It minimizes blocking troubles. Your sanding task remains cleaner. The disc remains cooler too. Overheating can mess up finishes. These discs help protect against that. They function well for fining sand primer. They also deal with filler material perfectly. You can use them on bare metal places. They are good for smoothing paint edges. The material bond holds the grit limited. This suggests regular efficiency. You obtain an also scrape pattern. The disc lasts longer. It does not shed grit swiftly. The mesh backing is flexible. It bends easily over contours. You can sand complicated forms better. The 125mm size fits typical orbital sanders. It is a typical dimension for information work. Aluminum oxide is tough. It cuts quick on several materials. These discs are created for specialists. They satisfy the needs of automobile stores. They provide dependable sanding power. They aid accomplish a smooth surface. This surface awaits paint.

(125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide)

Applications of 125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide

These 125mm material bond abrasive mesh fining sand discs are produced automobile body stores. They make use of light weight aluminum oxide abrasive. This product works well for many tasks in automobile painting. The mesh backing assists the disc remain flat. It stops obstructing too. Dust can get away via the holes. This keeps the disc reducing longer. The resin bond holds the rough firmly. It gives a consistent scratch pattern. This is important for a smooth finish.

Automobile specialists utilize these discs daily. They are best for fining sand body filler. The discs promptly get rid of high areas. They smooth rough filler surface areas before priming. The mesh style minimizes warm accumulation. This shields the filler below. You require a level surface area for paint. These discs help achieve that.

These discs additionally prepare bare metal. They remove light rust and deterioration. They create a mild profile for paint adhesion. Old paint layers need fining sand as well. The discs mess up the surface for new primer. The 125mm dimension fits conventional sanders. It covers area swiftly but permits control. You can sand rounded panels easily.

Light weight aluminum oxide cuts fast. It stays sharp longer than other abrasives. It manages challenging products like filler. It works with metals also. The material bond provides toughness. It uses evenly for foreseeable results. You avoid deep scratches by doing this. Regular scrape patterns are important. They avoid visible sanding marks under paint.

Technicians worth effectiveness. These discs conserve time. They last much longer than paper discs. The mesh does not tear quickly. You change discs less typically. They execute well on shapes. The flexibility adheres to the panel form. This offers a consistent surface everywhere. Utilizing these discs brings about far better paint jobs. They are an essential tool for expert refinishing job.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide

Here are five common questions about our 125mm resin bond abrasive mesh sanding discs. These discs are designed for automotive refinishing. People often ask what makes them different. They are built specifically for auto body work. The resin bond holds the aluminum oxide grit firmly. This bond is tough. It handles the pressures of sanding primer and paint. The bond resists loading too. It doesn’t clog up easily with sanded material.

Why is resin bond important? Resin bonds are durable. They last longer than other bonds under heavy use. Mechanics need discs that won’t wear out fast. Resin bonds deliver this. They maintain consistent performance. The abrasive cuts evenly throughout the disc’s life. You get a smooth finish without changing discs often.

Why use aluminum oxide? Aluminum oxide is a sharp abrasive. It cuts fast on auto paints and fillers. It is also versatile. You can use it for shaping filler or smoothing primer. Aluminum oxide is cost-effective. It gives good results without a high price. It works well for most tasks in a body shop.

What’s good about the mesh backing? The mesh backing is flexible. It bends easily over curves and contours. Auto panels have complex shapes. Mesh discs follow these shapes closely. Air passes through the mesh. This keeps the disc cooler. Cooler sanding means less heat buildup on the panel. Heat can damage paint or filler. Mesh also lets dust escape. Less dust buildup improves visibility. You see the surface better.

What grits are available? We offer various grits. Common choices are 80, 120, 180, and 240. Lower grits like 80 remove material quickly. They shape body filler fast. Higher grits like 180 or 240 prepare surfaces for paint. They create a fine finish. Choose the grit based on your sanding stage.

(125mm Resin Bond Abrasive Mesh Sanding Discs Specially Developed Automotive Refinishing Industry Aluminum Oxide)

REQUEST A QUOTE

RELATED PRODUCTS

Metallized Al2O3 Aluminum Oxide Substrate PCB Alumina Ceramic Sheet for Antenna Components

The Role of Aluminum Oxide in Revolutionizing Refractory Technologies

High-quality 96% Alumina Ceramic Substrate Insulation Aluminum Oxide Al2O3 Plate

Laser Scribing 96% 99.6% Aluminum Oxide Substrate Al2O3 Alumina Ceramic Plate

99% Alumina Tube Ceramic Tube / Ceramic Pipe