Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

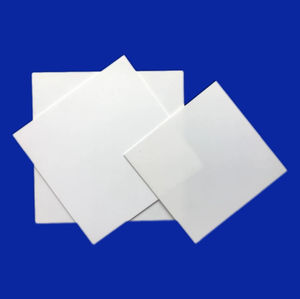

(2025 Customized Sizes New 99% Alumina Ceramic Parts)

Specifications of 2025 Customized Sizes New 99% Alumina Ceramic Parts

The 2025 Custom-made Sizes Brand-new 99% Alumina Ceramic Components are engineered for high-performance commercial applications. These parts make use of 99% light weight aluminum oxide as the main product. This guarantees outstanding mechanical toughness and resistance to extreme problems. Personalized measurements and shapes are readily available. Clients can ask for certain sizes to match distinct project requirements.

The material structure provides heat security. These parts deal with continuous use in atmospheres as much as 1650 ° C. Thermal shock resistance is strong. Rapid temperature changes do not create fracturing or deformation. Wear resistance is an additional crucial feature. The surface area solidity gets to 82 HRA, making the components ideal for abrasive settings.

Electrical insulation buildings are reliable. The alumina ceramic components protect against present leakage also under high-voltage conditions. This makes them perfect for electronic devices and power systems. Chemical resistance is equally durable. Acids, alkalis, and harsh gases do not harm the material. Long-lasting direct exposure to severe chemicals is convenient.

Surface surfaces can be changed. Alternatives include polished, matte, or distinctive layers. Precision machining ensures tight resistances. Dimensional accuracy meets criteria like ISO 2768. Applications cover several industries. Electronics make use of these components for shielding substrates and circuit elements. Automotive systems incorporate them right into sensors and engine elements. Medical gadgets take advantage of their biocompatibility and sterilizability. Industrial equipment counts on them for wear-resistant linings and cutting devices.

Lead times vary based upon order complexity. Requirement dimensions ship within 10 service days. Custom-made creates need added handling. Quality control consists of ultrasonic screening and density checks. Certifications cover ISO 9001 and RoHS compliance. Product packaging makes use of anti-static materials to avoid damage during transit. Technical assistance is available for design optimization and material option.

These alumina ceramic parts resolve the demand for durable, high-purity remedies. Their versatility suits both mass production and specialized low-volume tasks. Efficiency continues to be constant throughout diverse operational tensions.

(2025 Customized Sizes New 99% Alumina Ceramic Parts)

Applications of 2025 Customized Sizes New 99% Alumina Ceramic Parts

The 2025 Personalized Dimensions New 99% Alumina Ceramic Parts offer high performance for many sectors. These parts are made from innovative ceramic material. They take care of severe conditions better than metals or plastics. Their crucial functions include high firmness, warmth resistance, and chemical security. They last longer in rough settings.

In electronics, these ceramic components are used for shielding parts. Circuit boards and semiconductor tools require materials that prevent electric leaks. Alumina porcelains work well below. They maintain devices safe at high voltages. Sensors and ports additionally use these components for reputable performance.

The clinical field benefits from alumina porcelains. Surgical tools and implants call for materials that withstand rust. These components meet stringent sanitation criteria. Oral implants and joint substitutes utilize them for durability. They do not respond with body fluids. This makes them risk-free for lasting usage.

Automotive systems use these ceramics in engine components. Components like ignition system insulators deal with high temperatures. Alumina porcelains minimize wear and boost performance. Electric cars depend on them for battery components. They manage warm much better throughout quick charging.

Aerospace applications require products that survive extreme tension. Alumina ceramic components are made use of in generator coverings and heat shields. They safeguard devices from extreme friction and temperature levels. Satellite parts utilize them for security in space conditions.

Industrial equipment makes use of these components for reducing tools and seals. They stay sharp longer and lower downtime. Chemical plants make use of alumina porcelains in pumps and valves. They stand up to acid damage and avoid leakages.

Customized dimensions make these parts fit distinct demands. Makers offer precise shaping for customized tools. This flexibility supports development throughout sectors. The 2025 alumina ceramic components resolve challenges in modern environments. Their integrity and versatility make them essential for modern engineering.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 2025 Customized Sizes New 99% Alumina Ceramic Parts

Customers often ask about customized sizes for 2025 99% alumina ceramic parts. These parts are made to fit exact measurements. The process starts with a digital design. Precise machining follows. Sizes range from under 1mm to over 500mm. Tolerances stay tight. This ensures parts work in high-stress environments.

People want to know why 99% alumina is better. The material handles high heat. It resists wear better than metals or plastics. Chemical corrosion rarely affects it. Electrical insulation stays strong even at extreme temperatures. These traits make it reliable for industrial use.

Many ask where these parts apply. Electronics use them as insulating substrates. Automotive systems use them in sensors. Medical tools use them for biocompatibility. Machinery uses them in wear-resistant components. Custom sizes let them fit into existing setups without redesigns.

Questions about production time come up. Standard orders take 2-3 weeks. Custom sizes add 1-2 weeks for design checks. Prototypes are available for testing. Rush options exist for urgent needs. Delays happen if design changes mid-process.

Cost is a common concern. Prices depend on size and complexity. Larger parts need more material. Intricate shapes require advanced machining. Bulk orders lower per-unit costs. Surface treatments or coatings add expense. Quotes are free. Samples help estimate final costs accurately.

People check quality control methods. Each batch undergoes hardness tests. Density measurements confirm purity. X-ray scans find hidden flaws. Dimensional checks use laser tools. Performance tests mimic real-world conditions. Certifications like ISO 9001 ensure standards. Failed parts get recycled.

Durability questions are frequent. Lifespan depends on usage. Regular thermal cycling shortens it slightly. Abrasive environments cause gradual wear. Proper installation avoids cracks. Cleaning with harsh chemicals is not advised. Data sheets provide detailed maintenance tips.

(2025 Customized Sizes New 99% Alumina Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Provide Good high purity alumina Ceramic products in China

Square / Hexagon Al2o3 Alumina Ceramic Tiles and Plates

96% Metallization Tube Alumina Ceramics Parts Al2o3 Alumina Ceramic

One End Closed Insulating Al2O3 Alumina Thermocouple Ceramic Tubes Pipes

Customized Perforated Aluminum Oxide High Precision Alumina Ceramic