Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole)

Specifications of 27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole

The 27mm and 36.513 mm High Precision Zirconia Alumina Ceramic Round Porcelain Bearing Beans Balls Whole are crafted for requiring commercial applications. These ceramic balls are made from zirconia alumina, a material known for its stamina, longevity, and resistance to put on. The mix of zirconia and alumina develops a product with high solidity and superb thermal security. This makes the rounds appropriate for settings with extreme temperatures or mechanical tension.

The balls are manufactured to limited tolerances, guaranteeing constant shapes and size. Precision grinding and polishing processes accomplish smooth surfaces and roundness within micrometer-level accuracy. This level of precision lessens rubbing and resonance in revolving systems, boosting efficiency in bearings, shutoffs, pumps, and other machinery.

Available in two sizes– 27mm and 36.513 mm– the balls accommodate certain engineering demands. The bigger 36.513 mm version is excellent for sturdy applications requiring improved tons capacity. Both dimensions keep high dimensional stability under pressure, lowering contortion dangers during procedure.

Zirconia alumina ceramic rounds stand up to corrosion, chemicals, and oxidation. This makes them suitable for use in rough problems, including exposure to acids, antacid, or high humidity. Unlike metal spheres, they do not corrosion or weaken gradually, ensuring longer life span.

The non-conductive buildings of zirconia alumina make these balls valuable in electric or electronic systems where insulation is important. They also run successfully in high-speed applications because of reduced density, reducing centrifugal force and energy loss.

Modification alternatives include adjustments in dimension, surface coating, or product quality to fulfill unique job demands. Each batch undergoes rigorous quality checks to make sure compliance with market requirements.

Packaging is created to protect the balls from damages during delivery. They are commonly provided in safe and secure containers with anti-scratch padding. Proper handling and storage space standards are offered to keep product integrity.

These ceramic spheres are widely utilized in automobile, aerospace, medical gadgets, and precision instruments. Their integrity and efficiency make them a favored option for engineers looking for long lasting, high-performance elements.

(27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole)

Applications of 27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole

The 27mm and 36.513 mm high-precision zirconia alumina ceramic rounds are engineered for demanding applications. These ceramic bearing beads excel in settings calling for longevity, rust resistance, and very little rubbing. Their one-of-a-kind product buildings make them suitable for industrial, clinical, and high-tech uses.

In commercial equipment, these ceramic rounds are widely made use of in pumps, valves, and bearings. They take care of high-speed rotations and heavy tons without degrading. Their wear resistance decreases maintenance needs. They execute reliably in severe temperatures and harsh settings. This makes them suitable for chemical handling devices and oil drilling tools.

Medical tools take advantage of the non-reactive nature of zirconia alumina. The rounds are made use of in surgical tools, dental tools, and imaging equipment. They resist sterilization chemicals and physical fluids. Their smooth surface lessens bit generation, crucial for cleanroom environments. Precision production makes sure constant efficiency in sensitive clinical applications.

Aerospace and auto industries rely on these ceramic spheres for their lightweight toughness. They replace metal parts in advice systems, actuators, and turbochargers. Minimized weight boosts fuel performance. High thermal stability ensures capability in engines and exhaust systems. Their resistance to deformation under stress and anxiety boosts safety in crucial components.

Electronic devices producing uses these grains in adapters, sensors, and micro-motors. Electrical insulation protects against short circuits. The rounds’ hardness safeguards fragile components from abrasion. They preserve dimensional stability in damp or high-voltage conditions. This prolongs the life-span of digital tools.

Zirconia alumina ceramic balls are chosen for their crossbreed residential or commercial properties. They combine zirconia’s sturdiness with alumina’s hardness. This results in a product resistant to cracking and wear. The exact sizing (27mm and 36.513 mm) makes sure compatibility with standardized equipment. Personalized dimensions are readily available for specialized demands.

These ceramic balls are affordable with time. They outlast traditional steel or plastic choices. Decreased downtime and replacement costs benefit high-volume operations. Industries prioritize them for important applications where failing is not an option.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole

What materials are used in these ceramic balls? The balls are made from zirconia alumina. This material combines zirconium dioxide and aluminum oxide. It offers high hardness and wear resistance. These properties make it suitable for demanding applications. The mix ensures durability under extreme conditions.

Why choose 27mm and 36.513mm sizes? These sizes meet specific industrial needs. The 27mm and 36.513mm dimensions fit standard bearing systems. They provide precise performance in machinery requiring tight tolerances. Custom sizes are available for specialized uses. The focus is on delivering accuracy for mechanical efficiency.

How are the ceramic balls manufactured? Production uses advanced sintering techniques. Raw materials are compressed and heated to high temperatures. This creates a dense, uniform structure. Precision grinding follows to achieve exact dimensions. Each ball undergoes strict quality checks for roundness and surface finish.

What maintenance do ceramic balls require? They need minimal upkeep. Clean them regularly to remove debris. Avoid harsh chemicals that might damage the surface. Inspect for cracks or chips during use. Proper handling ensures long service life. Their corrosion resistance reduces routine maintenance needs.

Where are these ceramic balls commonly used? They serve in high-stress environments. Examples include aerospace components, medical devices, and precision instruments. They perform well in high-temperature or corrosive settings. Industrial pumps and automotive systems also benefit from their reliability. Their low friction improves energy efficiency in moving parts.

(27mm 36.513mm High Precision Zirconia Alumina Ceramic Ball Ceramic Bearing Beads Balls Whole)

REQUEST A QUOTE

RELATED PRODUCTS

High Al2O3 Content 95% Refractory Alumina Ceramic Rods Industrial Ceramic Pump Use High Temperature Resistant Custom Cut Sizes

Alumina Ceramic Plate

Square / Hexagon Al2o3 Alumina Ceramic Tiles and Plates

Aluminum Oxide Ceramic Lined Equipment for Mining

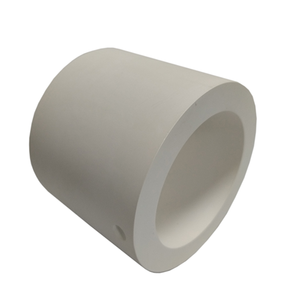

Alumina Metallized Ceramic Insulating Pipe for Industrial High Vacuum