Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

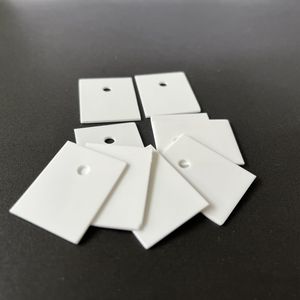

Introduction to 95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of 95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts)

Specifications of 95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts

This 95% light weight aluminum oxide ceramic block functions precision holes. It is a top choice for demanding commercial work. The product is mostly alumina. This makes certain piece de resistance under stress. It deals with extreme warm well. Temperatures reach 1600 ° C conveniently. Thermal shock resistance is strong. Sudden temperature level changes create couple of troubles. Electric insulation is superb. The block stops high voltage. Existing leakages are stopped properly. It works accurately in electric systems.

Density is high. This gives the block great strength. Firmness is also really high. Put on and abrasion rarely influence it. The surface remains smooth much longer. Holes are pierced specifically. Dimensions vary from 0.5 mm to 20mm. Patterns are custom-made. Round, square, or complicated shapes are possible. Opening positioning is accurate. This fits details mounting or circulation requirements. Customized sizes and thicknesses are available. Common blocks are 50x50mm up to 200x200mm. Density differs from 3mm to 25mm. Surface area surface is fine. Grinding achieves tight tolerances.

Chemical resistance is exceptional. Acids, alkalis, and solvents create little damage. It works well in extreme chemical setups. Mechanical toughness is impressive. The block births heavy tons. It lasts long under stress. This alumina ceramic matches lots of uses. Heater cellular linings, sensor owners, and insulating spacers are common. It also operates in semiconductor tools and laser components. The product gives dependable insulation and structure. It stands up to tough problems. Custom-made hole arrangements are possible.

(95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts)

Applications of 95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts

This 95% light weight aluminum oxide ceramic block with openings provides solid efficiency. It deals with high heat well. So it functions perfectly inside heating systems and kilns. It lines hot areas. It sustains heated parts. The openings let gases or liquids go through. This is important for lots of tasks.

It blocks electrical power dependably. So it protects sensitive electronic devices. Circuit boards utilize it. Power components utilize it. It maintains electrical paths safe. The holes enable wiring or cooling air via. It fits snugly around components.

It takes on difficult chemicals. Acids and bases don’t quickly harm it. So chemical plants utilize these blocks. They deal with destructive fluids. They work as reactor liners. They function as protective barriers. The openings take care of circulation inside pipelines or vessels.

It stays really hard and puts on slowly. Unpleasant materials cause little damage. So mining tools uses it. Pump parts use it. It lasts longer than steel in sandy problems. The holes direct slurry flow.

It keeps its form under anxiety. Size changes are very little with heat. So it gives exact positioning. Lab equipment uses it. Laser systems use it. Sensing units use it. The holes allow beams or probes through precisely.

Oil areas utilize them. They shield downhole tools from extreme warmth. They handle pressure. The holes let gases vent securely. Semiconductor tools utilize them. They insulate wafer processing components. The openings manage vacuum cleaner or cleanup gas flow. Industrial heating units use them. They support radiant warm elements. The holes allow warmth radiate out.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts

Product FAQ: 95% Aluminum Oxide Ceramic Blocks with Holes

1. What are these ceramic blocks exactly?

These are rigid parts made mostly from aluminum oxide (alumina). We make them very hard and dense. The blocks have holes drilled through them. These holes are precise. The blocks are designed for insulation and support in tough conditions.

2. Why use aluminum oxide ceramic blocks?

Alumina ceramic handles extreme heat very well. It resists wear and corrosion strongly. The material blocks electricity effectively. The holes let you mount components or run wires/coolants through. You get stability and protection where metals or plastics fail.

3. Are these blocks strong?

Yes. They are extremely hard. This hardness resists scratches and abrasion. They carry good mechanical loads. They withstand high pressure. But they are brittle like most ceramics. Avoid sharp impacts or heavy bending forces. Handle them carefully.

4. How hot can these blocks get?

They perform reliably up to about 1650°C (3000°F). Their strength stays high even near this limit. Thermal shock resistance is good. Sudden temperature changes usually won’t crack them. They insulate heat effectively too.

5. Can I get custom hole sizes and patterns?

Yes. We machine holes precisely. Tell us the diameter, depth, and locations you need. We can drill straight holes or complex patterns. We ensure the holes meet your exact requirements. Standard sizes are also available.

(95% Aluminum Oxide Ceramic Block with Holes Alumina Insulating Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Insulator Custom-made 95 Alumina Ceramic Part

95% 96% 99% Aluminum Oxide Ceramic Round Plate Disc

Steatite Ceramic Insulated Ceramic Structural Components Alumina Ceramic Assembly Parts

50mm 75mm 1” 2″ Tr/Ts Aluminum Oxide Ceramic Zirconia Alumina Silicon Carbide Quick Change Discs for Cleaning Polishing Surface Condition Customized

Aluminum Oxide Ceramic Mosaic Tile as Pulley Lagging Ceramics