Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

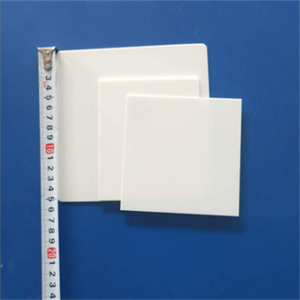

(96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part)

Specifications of 96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part

The 96% AL2O3 alumina ceramic component is a high-performance commercial material made largely from light weight aluminum oxide. This ceramic part supplies excellent mechanical toughness, use resistance, and thermal security. It is extensively made use of in demanding settings as a result of its reliability and durability. The alumina content of 96% guarantees a balance between cost-effectiveness and superior product homes.

The ceramic element has a density of about 3.7 g/cm THREE. It preserves high solidity, rated at around 80 HRA. This makes it immune to abrasion and surface damages. The flexural strength surpasses 300 MPa, making sure structural honesty under hefty lots. Compressive toughness is above 2500 MPa, permitting it to endure high-pressure problems.

Thermal buildings are essential for this product. The maximum operating temperature reaches 1600 ° C. Thermal conductivity is low, concerning 30 W/m · K, which aids in thermal insulation applications. The coefficient of thermal expansion is 7.2 × 10 ⁻⁶/ ° C, decreasing dimensional modifications during quick temperature level shifts. Electric insulation is another essential function, with a quantity resistivity of over 10 ¹⁴ Ω · centimeters. This avoids current leak in high-voltage or electronic systems.

Applications include usage in electronics, equipment, chemical equipment, and clinical devices. Common instances are shielding parts, wear-resistant linings, sealing components, and cutting tools. In electronics, it serves as substratums or insulators for circuits. Industrial equipment utilizes it for pump parts, shutoff seats, and grinding media. The chemical market benefits from its resistance to acids, alkalis, and harsh gases. Clinical gadgets like implants or surgical tools rely upon its biocompatibility and sterilization abilities.

Contrasted to metals or plastics, alumina ceramic elements last much longer in extreme problems. They reduce maintenance prices and downtime. Surface area smoothness can be personalized for reduced rubbing or precise resistances. Machining alternatives consist of grinding, brightening, or laser cutting to satisfy particular design demands.

The product is non-reactive and environmentally secure. It does not break down under UV direct exposure or dampness. Custom shapes and sizes are offered with pushing, extrusion, or injection molding. Quality control makes sure consistency in performance across sets. Testing approaches consist of X-ray evaluation, thickness checks, and strength confirmation.

Advantages over options include longer life span, minimized energy consumption, and compatibility with extreme settings. It is a cost-efficient solution for industries focusing on longevity and precision.

(96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part)

Applications of 96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part

96% Al2O3 alumina aluminum oxide ceramic elements are widely made use of in several sectors. They deal with high warm well. They withstand use efficiently. They shield electrical energy dependably. These residential properties make them appropriate for demanding settings.

In electronics, these ceramics are common. They make substratums for circuits. They create insulators in gadgets. They protect parts from overheating. Their stability makes certain lasting performance. They operate in sensing units and resistors. They maintain digital systems safe.

Industrial machinery makes use of alumina ceramic parts. They line pipes and chutes. They lower wear in unpleasant materials. They last longer than steel in severe conditions. They seal pumps and shutoffs. They avoid leaks in chemical procedures. Their hardness stands up to scratches. They reduced upkeep costs.

Medical tools benefits from these ceramics. They create tools for surgery. They stand up to repeated sterilization. They do not respond with body liquids. They are used in implants. They support oral applications. Their biocompatibility makes them risk-free.

The vehicle industry depends on alumina porcelains. They make spark plug insulators. They secure components from exhaust heat. They enhance engine effectiveness. They serve in sensors for exhausts regulate. They manage heats in braking systems. They lower part failing rates.

Aerospace applications require high-performance products. Alumina ceramics satisfy these needs. They layer parts subjected to severe warmth. They shield spacecraft elements. They secure against rust in fuel systems. They make certain integrity in vital goals.

Alumina porcelains are picked for their stamina. They run in temperatures over 1500 ° C. They resist chemical attacks. They keep form under anxiety. They offer expense financial savings through durability. They adjust to custom styles. They fulfill stringent market criteria.

These ceramic components support contemporary innovation. They solve obstacles in production. They enhance item life-spans. They make it possible for innovations across areas. Their flexibility makes them essential.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part

What is 96% Al2O3 alumina ceramic? This material is made mostly from aluminum oxide. The 96% refers to the purity level. It is a high-performance ceramic known for hardness, heat resistance, and strength. These parts work well in tough environments where metals or plastics might fail.

What are the main features of alumina ceramic parts? They handle temperatures up to 1700°C. They resist wear and corrosion better than many metals. They do not conduct electricity, making them good insulators. They stay stable when exposed to chemicals. These traits make them reliable for industrial uses.

Where are alumina ceramic parts commonly used? They appear in machinery, electronics, and medical equipment. Examples include seals, cutting tools, insulators, and lab devices. They protect sensitive parts from heat, friction, or chemical damage. Factories use them in high-stress processes like metal forming or semiconductor production.

How should alumina ceramic parts be installed? Handle them carefully to avoid chipping. Use tools softer than the ceramic, like rubber or plastic. Match the adhesive to the operating conditions. Clean surfaces before bonding. Follow manufacturer guidelines for pressure and temperature limits. Improper installation can cause cracks or reduce performance.

Can these parts be customized? Yes. Manufacturers adjust sizes, shapes, and surface finishes. Some parts have holes, threads, or special coatings. Provide exact dimensions and usage details for best results. Custom designs might take longer to produce. Testing ensures they meet specific needs.

(96% AL2O3 Alumina Aluminum Oxide Ceramic Component Alumina Ceramic Part)

REQUEST A QUOTE

RELATED PRODUCTS

Corrosion Resistance Aluminum Oxide Parts Low Maintenance Cost Ceramic Pump

High Quality 99% Alumina Ceramic Plate Al2o3 Ceramic Sheet Thin Plate

Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube

Alumina Ceramic Plate

Al2O3 Ceramic Tube Wear-Resistant Aluminum Oxide Plunger Industrial