Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

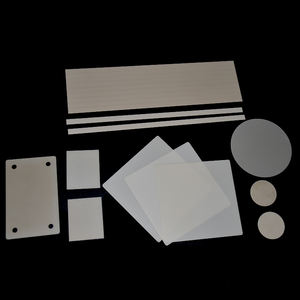

(99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant)

Specifications of 99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant

The 99% alumina ceramic plate is made for semiconductor applications. It provides high performance popular environments. The product consists of 99% light weight aluminum oxide. This guarantees marginal impurities. High purity is crucial for semiconductor processes. Pollutants can interfere with production. The plate satisfies strict industry requirements. It stands up to chemical corrosion. Acids and antacids do not damage it. This makes it appropriate for hostile setups. Use resistance is an essential function. The surface firmness goes beyond most metals. It maintains honesty under rubbing. Long service life lowers replacement costs. Thermal security is an additional advantage. The plate manages temperatures up to 1600 ° C. It does not deform or split under warmth. Fast temperature changes are endured. This avoids thermal shock failings. Electrical insulation homes are superb. The product obstructs current leak. This safeguards delicate semiconductor elements. Accuracy machining makes sure tight tolerances. Flatness and smoothness are managed. Dimensions can be tailored. Usual density varieties from 0.5 mm to 30mm. Sizes differ based upon customer requirements. Surface finishes are adjustable. Refined or matte options exist. Laser cutting is readily available for complex forms. The ceramic plate works in engraving tools. It is used in wafer processing stages. Plasma atmospheres do not weaken it. Vacuum compatibility makes certain no outgassing. This protects against contamination in sealed systems. Mechanical strength supports hefty loads. The flexural strength mores than 300MPa. It stands up to high-pressure problems. Cleaning up home plate is easy. Ultrasonic techniques or solvents job. No deposit stays after therapy. Custom-made markings or openings can be included. These adjustments aid in assembly processes. The item matches automated production lines. It incorporates with existing machinery. Technical support is offered installment. Evaluating information validates efficiency claims. Certifications include ISO and RoHS conformity. Mass orders have much shorter lead times. Samples are readily available for examination. Product packaging protects against damages throughout shipping. Each system is inspected before delivery.

(99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant)

Applications of 99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant

99% alumina ceramic plates serve crucial roles in semiconductor production. Their high purity makes them optimal for settings where contamination dangers must be reduced. These plates have 99% aluminum oxide, reducing the possibility of pollutants interfering with delicate procedures. Semiconductor production demands materials that hold up against extreme conditions. Alumina porcelains stand out right here due to their security under heats and destructive chemicals.

In semiconductor construction, these plates are made use of as substrates, insulators, or parts in tools. They deal with tasks like wafer processing, etching, or chemical vapor deposition. Their electrical insulation residential or commercial properties prevent existing leak, making sure specific control throughout operations. Thermal management is another vital advantage. Alumina plates distribute warmth evenly, stopping damages to fragile semiconductor components.

High purity is non-negotiable in semiconductor applications. Even trace impurities can destroy product high quality. Alumina ceramic plates satisfy stringent sanitation requirements. Their composition prevents launching fragments or gases throughout use. This reliability sustains constant efficiency in cleanroom setups. Surface level of smoothness matters too. Refined alumina plates reduce friction, lessening fragment generation throughout mechanical processes.

Wear resistance extends the life expectancy of alumina ceramic plates in high-stress environments. Semiconductor tools encounter constant friction, abrasion, and mechanical lots. Alumina’s solidity protects against surface degradation, preserving precision gradually. This durability cuts downtime for component substitutes, boosting manufacturing performance. Parts like robot arms or wafer trainers take advantage of alumina’s durability.

Chemical resistance adds worth. Alumina plates stand up to acids, alkalis, and solvents made use of in chip production. This stability ensures long-lasting use without corrosion or structural failure. Plasma environments pose no obstacle either. Alumina keeps integrity under ionized gas exposure, typical in etching or deposition systems.

Cost-effectiveness expands from alumina’s mixed properties. While first expenses might surpass some products, reduced maintenance and longer service life lower overall costs. Semiconductor makers prioritize such efficiency gains. Compatibility with sophisticated modern technologies like AI-driven automation or IoT-enabled systems further solidifies alumina porcelains’ function in modern electronics.

The demand for high-performance materials in semiconductors maintains increasing. Alumina ceramic plates address this requirement via flexibility, reliability, and precision. Their usage spans research labs to mass production facilities, confirming necessary ahead of time microelectronics.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant

What is a 99% alumina ceramic plate?

This ceramic plate is made from 99% pure aluminum oxide. It is designed for semiconductor applications. The high purity ensures minimal contamination. It resists wear, heat, and chemical damage. This makes it reliable for demanding industrial environments.

Why is high purity important for semiconductor use?

Semiconductor manufacturing needs clean materials. Impurities can disrupt production. The 99% alumina content reduces contamination risks. It keeps processes stable. This improves product quality and yield.

How does the plate resist wear?

Alumina ceramic has a hard, dense structure. It handles friction and abrasion well. The material’s toughness prevents cracks or chips. This extends the plate’s lifespan. It stays functional under heavy use.

Can it handle high temperatures?

Yes. The plate works in extreme heat. It withstands temperatures over 1500°C. Thermal stability prevents warping or breaking. This suits processes like wafer processing. Heat management stays consistent.

What applications use this ceramic plate?

It is common in semiconductor equipment. Examples include etching chambers and CVD systems. It also works in grinding and polishing tools. The plate’s durability supports precision tasks. It meets strict industry standards.

(99% Alumina Ceramic Plate for Semiconductor, High Purity, Wear Resistant)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Al2O3 Ceramics Precision Industrial CNC 99% 99.5% Alumina Ceramic Parts

High Heat Resistance 99% Alumina Ceramic Rod

Al2o3 High Precision 95 99 Wear Resistant Alumina Ceramic Plate

High Temperature Alumina Ceramic Sagger

High Temperature Porous Ceramics Alumina Ceramic Semicircle