Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

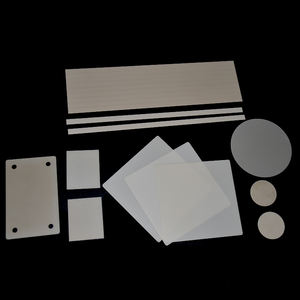

(99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe)

Specifications of 99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe

The 99% alumina ceramic tube is a high-performance material created for demanding commercial applications. This product supplies remarkable thermal security, mechanical stamina, and chemical resistance. The alumina material reaches 99%, guaranteeing premium efficiency contrasted to lower-grade porcelains. These tubes are available in numerous dimensions, making them appropriate for diverse usages.

The alumina ceramic tube endures severe temperatures as much as 1650 ° C. It preserves architectural stability under fast thermal biking. This makes it suitable for high-temperature atmospheres like heating systems or kilns. The product withstands rust from acids, antacid, and molten metals. It performs reliably in chemically hostile settings.

Mechanical residential properties include high solidity and wear resistance. Television’s compressive toughness goes beyond 2000 MPa, guaranteeing resilience under heavy tons. Its smooth surface decreases rubbing, reducing wear in relocating components. Electric insulation stays secure also at elevated temperatures. This residential property fits applications in electronic devices or high-voltage systems.

Sizes differ to satisfy certain requirements. External diameters vary from 2 mm to 150 mm. Inner diameters readjust according to wall surface thickness requirements. Basic lengths prolong as much as 1000 mm. Custom measurements are readily available upon demand. Tolerances are snugly controlled to make certain precision in important applications.

The production procedure uses high-purity alumina powder. Sintering at over 1700 ° C creates a dense, non-porous framework. This removes leakage threats in liquid transfer systems. Surface finishes can be polished or left as-fired based on application demands.

Applications extend several markets. Thermocouple defense sleeves use these tubes in temperature measurement systems. Semiconductor processing equipment depends on their pureness and warmth resistance. Laser elements gain from their stability and insulation residential properties. Industrial heating systems use them as insulation elements or heating element sustains.

Product packaging choices include foam-lined cartons or wooden dog crates for delicate things. Mass orders receive safety covering to stop transportation damage. Technical assistance helps with material option and layout requirements. Samples are available for testing compatibility with particular procedures.

The 99% alumina ceramic tube combines reliability with versatility. It addresses challenges in extreme operating problems. Efficiency consistency makes certain long life span, lowering replacement prices. Compatibility with automated systems supports modern-day manufacturing workflows.

(99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe)

Applications of 99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe

99% alumina ceramic tubes provide high efficiency popular settings. These ceramic pipelines are made from costs alumina material. They give superb thermal resistance, mechanical toughness, and electric insulation. Their high purity makes them suitable for industrial, electronic, and clinical applications.

These ceramic tubes work well in high-temperature settings. They stand up to temperatures as much as 1600 ° C without warping. Industries use them in furnace linings, kiln furnishings, and thermal handling equipment. Their security under warmth makes sure consistent procedure.

Electrical applications gain from their insulation residential or commercial properties. They avoid existing leakage in high-voltage systems. Semiconductor manufacturing uses them as safety sleeves for sensing units and heaters. Their non-conductive nature improves security in digital devices.

Chemical resistance is an additional essential feature. Alumina tubes withstand rust from acids, alkalis, and molten metals. Chemical plants utilize them for transporting aggressive liquids. Laboratories use them in response chambers and crucibles.

Various sizes expand their functionality. Small-diameter tubes fit accuracy tools like thermocouples. Bigger sizes take care of industrial fluid transfer or architectural elements. Custom lengths and densities satisfy details project demands.

Longevity reduces long-lasting expenses. Alumina ceramic pipelines outlast steel or plastic choices. They withstand wear, effect, and thermal shock. Very little upkeep is required over their life expectancy.

Selecting the appropriate dimension depends upon application needs. Temperature variety, pressure levels, and ecological problems issue. Engineers usually seek advice from producers to match specifications. Criterion sizes are offered for quick shipment. Personalized alternatives suit special layouts.

The product’s hardness guarantees dimensional stability. Precision machining allows limited tolerances for technological uses. Smooth surface areas protect against contamination in sensitive processes.

These tubes are suitable for aerospace and automotive markets. They work in engine elements, sensors, and exhaust systems. Clinical tools relies upon their biocompatibility and sterilizability.

Alumina ceramic pipelines equilibrium performance and usefulness. Their adaptability makes them important throughout sectors. Proper choice makes certain optimum results for each application.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe

What is 99% alumina ceramic tube? This ceramic tube is made from aluminum oxide. It contains 99% alumina. This gives high hardness, strength, and resistance to wear. It works well in extreme heat and corrosive settings. These tubes are good for industrial uses needing reliability.

How much heat can these tubes handle? The tubes handle temperatures up to 1800°C. They keep their shape and strength even under high heat. They resist thermal shock. Sudden temperature changes cause less damage compared to other materials.

What sizes are available? Standard sizes range from 1mm to 200mm in outer diameter. Lengths vary from 10mm to 1000mm. Custom sizes are possible. Manufacturers adjust dimensions based on project needs.

Where are these tubes used? They are common in industries like semiconductors, metallurgy, and chemical processing. They work as protective sleeves, insulators, or parts in furnaces. Labs use them for high-temperature experiments. Their corrosion resistance makes them fit for harsh chemical environments.

Can these tubes be customized? Yes. Customization covers dimensions, surface finish, and hole patterns. Special shapes or threaded ends are possible. Technical drawings help manufacturers meet exact requirements.

The material resists acids and alkalis. It stays stable in most chemicals. This prevents degradation over time.

Installation needs careful handling. Avoid mechanical impact during setup. Proper alignment ensures even stress distribution. Follow guidelines for thermal expansion to prevent cracks.

These tubes outlast metals and plastics in harsh conditions. Their low maintenance reduces long-term costs. Performance stays consistent under repeated thermal cycles.

Cleaning requires non-abrasive methods. Mild detergents and soft cloths prevent surface damage. Avoid harsh chemicals unless necessary. Regular checks for wear help maintain function.

Prices depend on size and complexity. Standard sizes cost less. Custom orders take longer and cost more. Bulk orders often have discounts.

(99% Alumina Ceramic Tube Various Sizes Alumina Ceramic Pipe)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Oxide Al2O3 Fine Powder for Ceramic Industry Alumina 92% 96% 98% Content Alumina Powder

zirconia/ aluminatriangular ceramic, insulating electrical ceramic components ceramics

Custom Durable Aluminum Oxide Ceramic for Industrial Use

Textile Ceramic Guide 95 99 Al2O3 High Performance Resistance Alumina Ceramic Parts

High Purity Al2O3 Alumina Ceramic Plate