Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

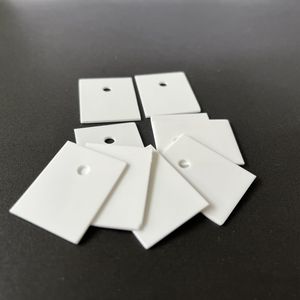

Introduction to Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics)

Specifications of Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics

These hexagonal light weight aluminum oxide tiles supply outstanding wear protection. They are developed hard for demanding commercial setups. The ceramic tiles step 50mm throughout each flat side. Requirement density is 10mm. Other sizes are offered on demand. Customized shapes are possible as well. The product mores than 95% pure aluminum oxide. This ensures exceptional firmness and thickness. The hardness rating surpasses 82 HRA. This high hardness directly fights surface area abrasion. The floor tiles stand up to continuous rubbing and scratching. They last a lot longer than moderate steel. They outperform rubber linings substantially. Influence resistance is another key strength. The ceramic tiles take in hefty strikes well. They prevent surface damage from falling objects. Heats are no worry. The tiles manage continual warm up to 1400 ° C. They withstand thermal shocks efficiently. Abrupt temperature level changes won’t fracture them. Chemical stability is exceptional. The ceramic tiles resist strike from acids and alkalis. They operate in harsh chemical atmospheres. Installation is straightforward. The ceramic tiles place safely onto steel structures. Mechanical dealing with uses countersunk bolts. Bonding utilizes high-strength epoxy adhesive. Both approaches make certain a solid, long lasting hold. The smooth surface area minimizes material accumulation. Mass products circulation easily over the tiles. Maintenance needs decrease considerably. Downtime decreases considerably. These ceramic tiles safeguard vital tools components. They secure hoppers, chutes, and shelters. They secure conveyor transfer factors. They line cyclones and classifier cones. They are vital for mining and power plants. They are vital in concrete production and steel mills. They conserve money by prolonging equipment life. They improve productivity by decreasing deductions.

(Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics)

Applications of Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics

These hexagonal light weight aluminum oxide ceramic tiles are exceptionally difficult. They manage serious wear and tear exceptionally well. Their solidity is exceptional. They resist scraping and gouging better than steel. This makes them perfect for protecting hefty machinery. Devices loses in several markets. These ceramic tiles shield it effectively.

You see them lining industrial chutes and hoppers constantly. Abrasive materials like coal, ore, and gravel circulation via these. Without defense, the metal wears quick. The ceramic tiles take the hit rather. They last a lot longer. This saves money on replacements and stops downtime.

Conveyor systems profit greatly also. Transfer points are important areas. Material drops onto belts below. This triggers significant impact and gliding wear. Lining these areas with the floor tiles prevents damages. Belts and underlying frameworks stay intact. Procedures run smoother.

Mining equipment requires this sturdiness. Excavator buckets, crusher linings, and testing decks deal with consistent abuse. Rocks and minerals grind against surfaces relentlessly. These alumina floor tiles absorb the influence. They extend the life of costly mining gear.

Steel plants use them in severe atmospheres. They line slag pots, troughs, and shelters. Warm, abrasive slag moves via these. The tiles stand up to the warm and the abrasion. They shield vital plant infrastructure.

Power generation centers count on them additionally. Coal handling systems are rough on tools. Ducts, pulverizers, and ash systems suffer wear. Mounting these tiles lowers maintenance migraines. They keep the power flowing.

The hexagonal shape is smart. It permits tight fitting on curved surface areas. Installment is simple. Workers bolt or glue them onto existing frameworks. No welding is required generally. This makes retrofitting simple. The floor tiles secure together well. This develops a strong, seamless barrier versus wear.

Makers last longer with this defense. Repair costs go down dramatically. Production uptime rises. That suggests real savings. These tiles are a smart protection versus consistent wear.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics

What makes these tiles resist wear?

These tiles use aluminum oxide ceramic. This material is incredibly hard. It fights off scratches and damage from constant rubbing. Things like heavy equipment or flowing materials won’t wear them down easily. They last much longer than regular steel surfaces.

Why are they shaped like hexagons?

The hexagon shape fits together tightly. This leaves very small gaps between tiles. Less gap means less weak spot for wear to attack. Stuff flowing over the surface hits the hard tile, not the gaps. This shape also makes them simple to install on curved surfaces.

How do you install them?

You stick them onto your existing equipment surface. Use a strong epoxy adhesive. Make sure the surface is clean and rough first. Press each tile firmly into place. The hexagon shape lets you cover complex shapes well. Proper installation is key for them to work best.

Are ceramics better than steel liners?

Yes, for resisting wear they are much better. Aluminum oxide ceramic is much harder than steel. It can handle abrasive materials like coal, ore, or sand far longer. Steel wears out fast in these conditions. Ceramics last many times longer, saving replacement costs.

How long will they last?

Their lifespan depends on the specific wear conditions. Factors include what material hits them and how fast it moves. In tough settings, they easily last several years. They often outlast the equipment they protect. This makes them a very cost-effective solution over time.

(Abrasion Resisant Hexagonal Aluminum Oxide Tiles Wear Resistnt Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Al2O3 Aluminum Oxide Ceramic Cap

Low Thickness White Alumina High end Ceramic Substrate Carved Aluminum Oxide Ceramics

99% Alumina Tube Ceramic Tube / Ceramic Pipe

95 Alumina Ceramic Sheet Ceramic Substrate Alumina Plate

Insulating 95% Alumina Ceramic Gasket Wafer Al2o3 Spacer For Electronic