Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

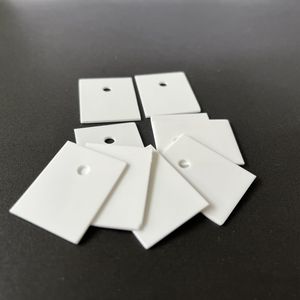

Description

Introduction to Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod)

Specifications of Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

This stirring pole uses alumina ceramic. Alumina is aluminum oxide. Its chemical formula is Al2O3. This product is really hard. It withstands wear incredibly well. The pole has high thickness. Thickness is commonly around 3.9 g/cm THREE. This makes it solid. It withstands heavy loads without breaking. Alumina deals with high warmth. Its optimum continual usage temperature level has to do with 1600 ° C. It won’t melt easily. The pole has low thermal growth. Temperature level adjustments cause marginal size variant. This prevents cracking under thermal shock. The surface is very smooth. This surface avoids example contamination. Particles will not stick quickly. The pole is chemically inert. It resists strong acids and bases. Usual laboratory chemicals do not harm it. It works with aggressive solvents. The rod is non-porous. Liquids can not permeate into the material. This maintains it tidy and sterile. Dimensions are precise. Length and size tolerances are tight. This ensures consistent efficiency. The rod is electrically insulating. It will not conduct electrical power. This is safe for numerous procedures. Alumina is biocompatible. It suits pharmaceutical and food applications. The rod is optimal for blending viscous liquids. It stirs molten metals safely. It agitates harsh chemical options. Lab professionals use it daily. Industrial procedures rely on its resilience. It replaces steel rods in harsh settings. Steel poles wear away. Alumina rods do not. This guarantees long service life. It requires little maintenance. Basic cleansing is sufficient. The rod uses dependable mixing. It supplies regular outcomes experiment after experiment.

(Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod)

Applications of Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

Al2O3 alumina aluminum oxide ceramic stirring poles are essential devices for demanding laboratory work. They take care of challenging conditions quickly. These rods stand up to severe heat. They work well over 1000 ° C. Chemical resistance is another key advantage. Acids, antacid, and solvents don’t damage them. Metal contamination is a trouble elsewhere. Ceramic rods avoid this totally. They maintain experiments pure.

Lab technicians make use of these poles daily. They stir corrosive fluids securely. High-temperature reactions require dependable tools. Alumina poles provide below. Semiconductor making counts on them as well. They blend delicate slurries without including contaminations. Drugs benefit in a similar way. Drug options remain unpolluted during preparation.

Industrial setups utilize these poles widely. Paint production calls for consistent stirring. Ceramic rods withstand aggressive solvents. Glue producing uses them similarly. They outlast metal options conveniently. Breakage is unusual. Glass stir poles smash typically. Alumina poles are almost solid. They conserve substitute expenses long-lasting.

Cleansing is uncomplicated. A straightforward rinse gets rid of most deposits. Autoclaving decontaminates them properly. They stand up to duplicated sanitation cycles. Surface area smoothness prevents product accumulation. This ensures constant performance every single time. Electrical insulation matters in some applications. These rods do not conduct electrical energy. They are safe around real-time circuits.

Sturdiness makes them cost-effective. Labs lower devices costs. Downtime reduces dramatically. Research high quality improves with trustworthy tools. Alumina stirring poles meet these needs flawlessly. They are a clever selection for specialists.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

Al2O3 Alumina Ceramic Stirring Rods: Key Questions Answered

What exactly is this stirring rod made from?

This rod is made from Al2O3, alumina ceramic. Alumina is a very hard, man-made material. It comes from aluminum oxide. It is not metal or plastic.

How much heat can it take?

Alumina ceramic handles extreme heat well. It works fine in temperatures up to about 1600°C (2912°F). Ordinary glass rods crack much sooner. This rod is good for very hot liquids or open flames.

Will chemicals damage it?

Alumina resists almost all chemicals. Strong acids and strong bases won’t hurt it. Hydrofluoric acid and very strong phosphoric acid can damage it. For most lab chemicals, it is safe. It won’t rust or corrode like metal.

How do I clean it?

Cleaning is simple. Use hot water and regular lab detergent. Soap and water work fine. You can also use dilute acids or bases if needed. Rinse it well with water afterwards. It can handle most cleaning methods.

Why pick this over a glass rod?

Alumina ceramic is much tougher than glass. It won’t chip or break easily from bumps. It handles sudden temperature changes better. It resists scratches far more than glass. It lasts much longer under tough lab conditions. You get better durability.

(Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Oxide Al2O3 Polishing Knitting Machine 99% Ceramic Saddle Guide

95% Alumina Ceramic Fixing Parts Aluminum Oxide Porcelain Element

Factory Customized High Purity 99.5% High Temperature Al2O3 Aluminum Oxide Ceramic Ring Alumina Ceramic

Customized China 95%99% Alumina Industrial Wear-Resistant Ceramic Tube Aluminum Oxide Al2O3 Alumina Ceramic Tube

Zirconia Ceramic Basket Gemstone with Aluminum Oxide Touch by Gravel