Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

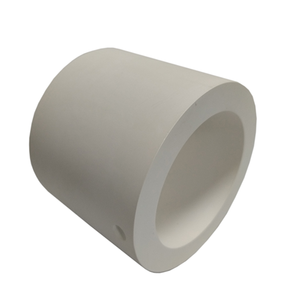

Introduction to Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples)

Specifications of Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples

These Alumina 92% floor tiles are difficult ceramic armor for commercial tools. They safeguard surfaces from extreme damage. The major product is light weight aluminum oxide, Al2O3. It composes 92% of the ceramic tile. This high alumina content provides the ceramic tile exceptional solidity. Hardness is near 9 on the Mohs scale. That means it stands up to scraping and abrasion quite possibly. These tiles deal with heavy impacts too. They will not split quickly under force.

The surface area features shaped dimples. These little indentations are essential. The dimples provide the epoxy adhesive extra area to grip. This creates a strong mechanical lock. The bond in between ceramic tile and steel substratum is much stronger. It protects against the ceramic tile from detaching under stress. Think of the dimples like supports. They hold the floor tile securely in place.

The mosaic layout makes use of small ceramic tile pieces. Usually, these items are 10x10x5mm or 17x17x5mm. Smaller floor tiles fit rounded surface areas much better. They line intricate shapes like pipelines and cyclones properly. The mosaic format lessens gaps. This develops a nearly seamless protective layer. Equipment remains safeguarded much longer.

Setup is uncomplicated. Workers bond the tiles directly onto steel surface areas using epoxy resin. The dimpled back makes certain a safe and secure fit. The floor tiles create a continual, high-wear cellular lining. This lining guards tools from constant friction. It protects versus abrasive materials like coal, ore, and concrete. Chemical resistance is an additional benefit. The floor tiles endure corrosive substances. They are optimal for requiring settings.

These tiles are common in mining, nuclear power plant, and material handling. Utilize them in chutes, receptacles, transfer factors, and mills. They considerably expand tools life. They reduce expensive downtime for repair services. The dimpled Alumina 92% mosaic tile uses reputable, lasting defense.

(Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples)

Applications of Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples

Alumina 92% Al2O3 ceramic mosaic tiles provide solid defense. These floor tiles are extremely hard. They stand up to put on extremely well. This makes them best for challenging industrial tasks. The high alumina content gives them this toughness. They handle hefty impacts and consistent abrasion without damaging down.

These ceramic tiles have an unique layout. The surface area features dimples. These dimples are essential. They give glue more surface to grip. This produces a much stronger bond in between the tile and the steel surface beneath. The bond lasts much longer. Tiles stay securely connected also under heavy tons and resonance. This avoids tiles from falling off unexpectedly. It reduces upkeep expenses and downtime.

Setup is straightforward. Employees adhesive the tiles directly onto steel structures. The mosaic layout makes use of numerous small tiles. This enables them to fit bent surfaces quickly. It likewise indicates less tension on each ceramic tile. Private ceramic tiles can absorb effects better. If one floor tile obtains harmed, changing it is straightforward. Employees only require to transform the damaged piece, not the entire lining.

These tiles work in lots of demanding settings. Use them in coal handling systems. They secure chutes, hoppers, and shelters from wear. Mining equipment advantages substantially. Crushers, displays, and cyclones last much longer with this cellular lining. Cement plants make use of these tiles in raw mills, clinker chutes, and finish mills. Power plants install them in ash handling air ducts and cyclones. Steel mills apply them to sinter plants and blast furnace equipment. Anywhere product streams quickly and triggers wear, alumina 92% ceramic tiles give trusted protection. They prolong devices life substantially.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples

People often ask what alumina 92% ceramic mosaic tiles are. They are small, tough tiles made mostly from aluminum oxide. The tiles have raised bumps called dimples on one side. People install them on surfaces needing protection.

Another question is why the tiles have dimples. The dimples create a stronger bond with glue or welding paste. This stops the tiles from coming loose easily. The dimples also let air escape during installation. This prevents air pockets weakening the bond.

People want to know where to use these tiles. Use them in heavy industrial places. They protect equipment from wear and abrasion. Common spots are hoppers, chutes, bunkers, and pipes handling abrasive materials like ore or sand. They shield surfaces effectively.

Many ask how tough these tiles really are. They are very hard and resist wear extremely well. They handle high temperatures without damage. They resist chemical attack from many substances. They last much longer than steel in abrasive conditions. This saves money on replacements.

Installation is a common concern. You attach the tiles using special adhesive or weld them. The dimpled side always faces the surface being protected. The smooth side faces the material flow. This setup gives the best wear resistance and grip. Proper installation is key for long life.

(Alumina 92% Al2O3 Ceramic Mosaic Aluminum Oxide Lining Tile with Dimples)

REQUEST A QUOTE

RELATED PRODUCTS

Customization 99% Alumina Ceramic Tube For Furnace Heater

Aluminum Oxide in Medicine: Innovations in Biocompatible Materials and Implants

Aluminum Oxide Ceramic Tube for Industry

High Whiteness 99% Aluminum Oxide White Powder for Ceramic Industry

High Temperature Resistance Customized High Quality Glazed Alumina Ceramic Filter Tips Smoking Filter