Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors)

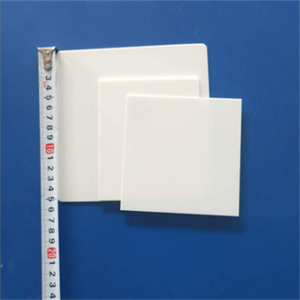

Specifications of Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors

Alumina ceramic shaft bettors and bushings serve vital roles in oxygen sensors. These parts are made from high pureness light weight aluminum oxide. This product is very tough. It withstands wear remarkably well. The surface stays smooth also after long use. This is important for consistent sensor efficiency.

Reduced elastic pressure issues greatly. The plunger applies minimal springtime stress. This ensures reliable call without damaging delicate sensor components. Such specific control maintains signal accuracy over time.

These ceramic parts deal with intense warmth conveniently. Oxygen sensors run in really warm exhaust settings. Alumina remains stable and strong also above 1000 ° C. It does not warp or compromise substantially. This thermal dependability avoids sensor drift.

Electrical insulation is another vital benefit. Alumina ceramic does not carry out electrical power. It effectively separates sensor signals. This avoids electrical shorts and disturbance. Signal stability continues to be high.

Chemical resistance is fundamental. Alumina endures severe exhaust gases. It doesn’t rust or react with impurities. This sturdiness makes sure lengthy life span. The part maintains operating dependably in aggressive problems.

The smooth surface coating decreases rubbing. The plunger relocates openly within the bushing. Consistent motion is important for exact oxygen degree analyses. Low rubbing protects against sticking and makes sure receptive operation.

These alumina elements are particularly created for demanding sensor applications. They provide the necessary solidity, thermal security, and electric residential or commercial properties. Oxygen sensing units depend upon these features for exact dimension.

(Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors)

Applications of Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors

Alumina ceramic shaft bettors with reduced flexible force matter for oxygen sensing units. These components are made from light weight aluminum oxide ceramic. That product is extremely hard. It withstands heats well. Oxygen sensing units operate in challenging places like auto exhausts. Exhausts get incredibly hot. Alumina ceramic handles that warm easily. Various other materials could fall short. These plungers also face chemical attack. Gas exhaust consists of harsh gases. Alumina ceramic disregards these chemicals. It does not wear away promptly. This maintains the sensor working precisely much longer.

The low elastic pressure style is key. The bettor requires simply the best pressure inside the sensing unit. Way too much force triggers troubles. It can damage the sensing unit element. It may scuff the surface area. Inadequate force is bad likewise. The sensing unit analyses end up being unsteady. The readings might be slow-moving or wrong. The low elastic force plunger addresses this. It uses constant, gentle pressure. This makes certain trustworthy contact without damage. Sensing unit efficiency remains consistent.

Durability is another big plus. Steel parts in sensors wear out quicker. Warm and chemicals attack them. Alumina ceramic plungers last much longer. They don’t warp or degrade like plastic can. Their solidity avoids scratching. This lengthy life minimizes sensing unit failings. It means fewer substitutes. Car makers desire reliable parts. These ceramic plungers provide that integrity. They assist the oxygen sensor measure oxygen degrees precisely for several years.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors

Alumina Ceramic Shaft Plunger: Oxygen Sensor Bushing FAQs

1. What is this alumina ceramic bushing made of?

It’s made of aluminum oxide ceramic. This material is very hard. It withstands high temperatures well. It resists corrosion effectively. These properties are vital inside oxygen sensors.

2. What does this ceramic plunger actually do?

It guides the sensor’s moving shaft precisely. Its low elastic force is key. It minimizes friction against the shaft. This ensures smooth, consistent movement. Accurate sensor readings depend on this smooth motion.

3. Why use ceramic instead of metal here?

Ceramic handles exhaust heat much better than metal. Metal can warp or wear down faster. Ceramic stays dimensionally stable under heat. It also electrically insulates the shaft. This prevents false signals in the sensor circuit.

4. How important is the low elastic force feature?

Extremely important. Too much force fights the shaft movement. This causes sluggish response or sticking. The sensor signal becomes inaccurate. Our plunger applies minimal force. This guarantees the shaft moves freely.

5. Will this bushing last a long time?

Yes, alumina ceramic is very durable. It resists extreme heat cycles constantly. It doesn’t degrade from exhaust gases. Its hardness prevents rapid wear. You get reliable performance over the sensor’s lifespan.

(Alumina Ceramic Shaft Plunger Low Elastic Force Aluminum Oxide Ceramic Bushing for Oxygen Sensors)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Al2O3 Ceramic Guides For Textile Machinery

Customized High Purity 99% Al2O3 Flat Bottom Crucible Alumina Ceramic Cup for Refractory Industry

Round 96 99.6 Aluminum Oxide Substrate Alumina Al2O3 Ceramic Wafer

99.8% Alumina Ceramic Textile Spiral Bobbin

High Temperature 99 Alumina Ceramic Small Crucible / Sample Pan for Tga with D6.5mm and D6.8mm