Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube)

Specifications of Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube

Alumina ceramic tubes use trusted performance sought after atmospheres. These tubes handle extreme temperatures, withstand wear, and can be personalized for certain requirements. The product structure is 95% alumina or greater, making certain superb thermal stability and mechanical stamina. The operating temperature level variety reaches up to 1800 ° C, making them ideal for high-heat applications. Customized measurements are offered, with external diameters from 2mm to 200mm and sizes approximately 2000mm. Surface area finishes differ from conventional to precision-polished, depending upon application needs.

High-temperature ceramic tubes preserve architectural stability under long term thermal stress. They exhibit reduced thermal development, decreasing deformation risks throughout quick temperature modifications. These tubes are chemically inert, standing up to corrosion from acids, antacid, and molten metals. Common usages consist of heater linings, thermocouple protection, and semiconductor processing tools. The dielectric stamina exceeds 15 kV/mm, ideal for electric insulation in harsh problems.

Customized wear-resistant ceramic tubes prioritize toughness in abrasive settings. Firmness degrees reach 85 HRA or higher, outshining most steels and polymers. These tubes reduce devices downtime in mining, power generation, and material handling systems. Alternatives consist of straight, tapered, or threaded layouts to match machinery requirements. Wall density can be changed in between 1mm and 50mm based on load-bearing needs. Some styles include flanges, grooves, or placing attributes for smooth assimilation.

Mechanical homes consist of a compressive stamina over 2200 MPa and a flexural strength of 300 MPa. The density varies from 3.6 to 3.9 g/cm FOUR, stabilizing weight and toughness. Surface area treatments like glazing or laser engraving improve functionality in specialized setups. Resistances are managed within ± 0.5% of small measurements for precision applications.

Quality control procedures involve ultrasonic testing, dimensional confirmation, and thermal cycling tests. All items meet ISO 9001 criteria for uniformity and performance. RoHS conformity guarantees environmental safety. Custom orders normally require 2-4 weeks for manufacturing, depending upon intricacy. Technical support is readily available for material option, setup guidance, and failure evaluation.

(Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube)

Applications of Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube

Alumina ceramic tubes serve numerous functions across different markets. These tubes manage extreme warm well. They work in areas like heaters and kilns. High thermal stability makes them last much longer in hot atmospheres. Electronic devices business use them to shield components. They protect sensitive elements from overheating. Their electric insulation residential or commercial properties add worth in power systems.

High-temperature ceramic tubes focus on withstanding warmth damages. Factories utilize them in metal processing. They line burning chambers and exhaust systems. Aerospace applications rely upon them for engine parts. These tubes make it through repeated heating and cooling down cycles. Chemical plants select them for corrosive setups. Acids and antacids do not easily break them down.

Personalized wear-resistant ceramic tubes take on abrasion problems. Mining procedures mount them in equipment like pumps and pipes. Difficult products like alumina extend the life expectancy of equipment. Cement plants utilize these tubes to move raw materials. The inner surface areas remain smooth despite continuous friction. Power generation centers use them in coal handling systems. Lowered maintenance requires conserve money and time.

Tailored styles satisfy particular market needs. Sizes and shapes get used to fit special machinery. Some tubes incorporate high-temperature and wear-resistant attributes. Manufacturers check each product for performance under anxiety. Custom-made layers or included layers improve toughness. Clients give specs for density, length, or mounting options.

Alumina ceramic tubes provide expense performance over time. Their sturdiness decreases substitute frequency. Energy industries utilize them in rough drilling problems. Medical devices use them for specific high-heat procedures. Research study laboratories use these tubes in experimental configurations. Regular performance ensures trusted results.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube

Alumina ceramic tubes are made from aluminum oxide. The material has high purity. It is processed under high temperatures. This makes the tubes strong and durable. They handle extreme heat well. They resist chemical corrosion too. These tubes work in harsh environments. They last longer than metal parts.

What temperature can alumina ceramic tubes handle? They withstand up to 1700°C. Their structure stays stable under heat. Thermal shock resistance is high. Sudden temperature changes don’t damage them. They cool or heat quickly without cracking. This suits furnaces and kilns.

Can these tubes be customized? Yes. Sizes and shapes are adjustable. Molding or machining creates specific designs. Custom lengths and diameters are possible. Surface finishes are tailored for needs. Threads or grooves are added. Wear-resistant versions include extra coatings.

Why choose alumina tubes for wear resistance? Their hardness is higher than steel. Abrasion from particles causes minimal damage. Smooth surfaces reduce friction. This slows wear in high-contact areas. They replace metal parts in mining equipment. Lifespans improve in gritty conditions.

Where are these tubes commonly used? Metallurgy uses them for molten metal handling. Chemical plants rely on corrosion resistance. Electronics employ them as insulators. Aerospace applications need heat protection. Medical devices use their biocompatibility. They fit anywhere durability matters.

How to maintain alumina ceramic tubes? Cleaning requires non-abrasive methods. Mild detergents prevent surface damage. Avoid impacts during handling. Storage needs dry conditions. Regular checks spot cracks early. Proper care extends service life.

(Alumina Ceramic Tube/high Temperature Ceramic Tube/ Customized Wear-resistant Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High temperature insulation alumina ceramic tube / porous alumina ceramic tube

Solid Nonporous Sintered Alumina Ceramic

High Purity Al2O3 99.7% Alumina Ceramic Small Tube

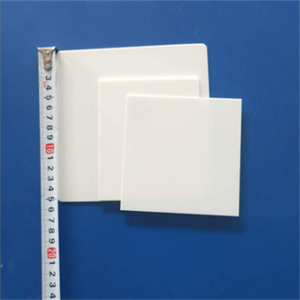

92% Alumina Ceramic Lining Tiles Aluminum Oxide Ceramic Wear Liner Mosaic Hexagonal Tiles

High Temperature Chemical Industrial 92 95 Al2o3 High Alumina Ceramic Plate