Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

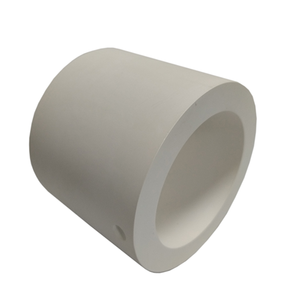

Introduction to Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing)

Specifications of Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing

Light weight aluminum oxide ceramic tubes, shafts, and tubing provide remarkable performance. These elements are made from high-purity alumina. This product is unbelievably difficult. It stands up to wear very well. Parts last longer sought after problems. They take on abrasion far better than numerous metals.

These ceramics are solid mechanically. They deal with considerable lots without bending. They give outstanding dimensional security. Sizes remain constant via temperature level adjustments. This is crucial for accuracy applications. Alumina is also an electric insulator. It stops present circulation successfully. This residential property serves in electronic devices and high-voltage setups.

Warmth resistance is another essential benefit. These components operate reliably at really heats. They endure thermal shock reasonably well. Unexpected temperature changes cause much less fracturing. Chemical resistance is additionally impressive. Alumina resists attack from numerous acids and bases. This makes it appropriate for severe chemical settings.

The surface area coating is important. Our tubes, shafts, and tubing feature a polished surface. This polishing lowers rubbing dramatically. Smoother surfaces suggest less wear gradually. It also boosts securing capacities. Sleek alumina is very smooth. It really feels virtually glass-like.

We offer various shapes and sizes. Criterion sizes are readily available. Customized sizes and sizes are feasible. Wall surface thicknesses can be specified. Tolerances are held snugly. This ensures parts fit correctly in settings up. We supply solid rods (shafts) and hollow tubes (tubing).

These parts fit numerous industries. They function well in semiconductor manufacturing devices. They are common in clinical gadgets. Analytical instruments utilize them often. Industrial equipment gain from their wear resistance. Electrical insulators are a significant application. Anywhere requiring firmness, warm resistance, or electric insulation is a prospective use.

(Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing)

Applications of Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing

Light weight aluminum oxide polished ceramic tubes, shafts, and tubes deal with tough jobs. They function where steels fall short. Heat does not bother them. They stand up to really heats. Chemicals rarely strike them. They stay solid against acids and bases. They wear down very gradually. Friction and abrasion trigger little damages. They shield electrical energy perfectly. Sparks are not a trouble. These buildings make them essential parts.

Semiconductor manufacturers require them. They relocate destructive gases safely. They hold silicon wafers safely. Furnace components utilize them daily. They handle extreme warm cycles. Laboratory equipment depends on them. Stirrers need chemical resistance. Taste holders demand purity. They never contaminate experiments. Medical devices benefit also. Biocompatibility is crucial. They function inside imaging equipments. They lead laser light beams properly.

Industrial pumps utilize ceramic shafts. Seal encounters last a lot longer. Bearings run smoother. Much less rubbing suggests much less power. Much less put on ways much less downtime. Thermocouple tubes secure sensors. They offer accurate readings. High warm doesn’t distort them. Textile guides avoid fixed. Fibers move easily. Cord forming tools keep form. They resist consistent abrasion. Laser system parts need precision. They concentrate light accurately. They stay cool under power.

These ceramic components address issues. They supply a dependable option. They do in severe problems. They last much longer than metal. They minimize upkeep expenses. They improve process reliability. Lots of markets depend on them.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing

What are Aluminum Oxide Polished Ceramic Tubes made of?

They are made almost entirely of aluminum oxide ceramic. This material is very hard. It gets polished to a very smooth finish. This finish reduces friction. It also makes them look good.

Why use these polished ceramic tubes or shafts?

They handle extreme conditions well. They resist very high temperatures. They are excellent electrical insulators. They are very hard. This means they resist wear and abrasion extremely well. They are also chemically inert. So they won’t react with most acids or alkalis. This makes them reliable in tough environments.

Where are these polished ceramic tubes typically used?

You find them in many industrial jobs. They work well as guide shafts in machinery. They are good for furnace rollers because they handle heat. They are used in semiconductor equipment. They are used in medical devices. They are used in laser systems. They are used where smooth surfaces, precision, and durability matter most.

How precise are the dimensions of these polished tubes?

They are made to very tight tolerances. The polishing process ensures consistent outer diameters. It also ensures smooth inner bores. This precision is critical. It is needed for proper fit and function in assemblies. It minimizes vibration. It reduces wear in moving parts.

Can these ceramic tubes be customized?

Yes, they often can be. Manufacturers offer different lengths. They offer different outer diameters. They offer different inner diameters. They offer different wall thicknesses. Special end features might be possible. Special surface finishes might be possible. Specific tolerances can usually be met. Check with the supplier for exact options.

(Aluminum Oxide Polished Ceramic Tubes, Shafts & Tubing)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Catalyst Carrier 10mm 13mm 16mmHollow Perforated Porous Alumina Ceramic Balls

Industrial Insulation High Precision Customized High Purity OEM Ceramics 95% 99% 99.5% Structural Parts Alumina Ceramic

99.5% Aluminum Oxide Al2o3 Alumina Ceramic Saggar Box for Industrial Furnace

High Al2O3 Aluminum Oxide Ceramic Parts Alumina Ceramic

China Hexagonal 92% 95% Alumina Ceramic Mosaic Aluminum Oxide Lining Tiles