Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

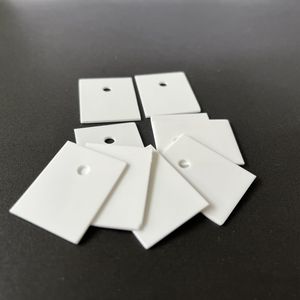

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity)

Specifications of Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity

Custom-made large-diameter alumina ceramic corundum tubes and alumina ceramic crucibles are developed for high-temperature commercial applications. These items are made from high-purity alumina (Al two O THREE) with a content of 99% or greater. This ensures superb chemical security and resistance to destructive environments. The material structure additionally offers remarkable mechanical strength, making televisions and crucibles suitable for harsh operating problems.

The alumina ceramic corundum tubes are offered in diameters varying from 50mm to 500mm. Wall thickness varies between 5mm and 30mm to accommodate different thermal and mechanical needs. Custom lengths up to 2000mm can be produced based upon customer requirements. The alumina ceramic crucibles been available in several dimensions, with capacities from 100ml to 5000ml. Both products are produced making use of advanced sintering strategies, making certain thick frameworks and marginal porosity.

High durability is a key function of these porcelains. They stand up to temperatures as much as 1800 ° C without deformation or degradation. Their thermal shock resistance permits fast home heating and cooling down cycles without cracking. This makes them optimal for applications like steel melting, semiconductor handling, and lab experiments. The reduced thermal expansion coefficient reduces stress and anxiety under temperature level changes, extending life span.

Thermal conductivity is maximized for efficient heat transfer. The alumina ceramic’s high thermal conductivity guarantees uniform temperature distribution in furnaces or activators. This building boosts procedure uniformity and power efficiency. The smooth surface finish reduces product bond, streamlining cleaning and upkeep.

These products are extensively made use of in markets such as aerospace, metallurgy, and chemical design. They function as linings for kilns, protective sleeves for thermocouples, and containers for liquified steels. Customization options consist of certain dimensional tolerances, surface sprucing up, and threaded links. The porcelains are electrically insulating, adding safety in high-voltage environments.

Material pureness and architectural integrity are examined rigorously before delivery. X-ray and ultrasonic examinations identify internal problems. Hardness and density dimensions confirm compliance with industrial standards. The products are packaged securely to avoid damage during transit. Preparations depend upon order specs however normally range from 2 to 6 weeks.

(Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity)

Applications of Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity

Custom large-diameter alumina ceramic corundum tubes and alumina ceramic crucibles serve essential roles in sectors needing high-temperature stability and chemical resistance. These parts are widely utilized in metallurgy, semiconductor production, chemical handling, and advanced material research study. Their main benefits depend on remarkable sturdiness and effective thermal conductivity, making them perfect for extreme environments.

Alumina ceramic diamond tubes are crafted from high-purity alumina. This material endures temperatures exceeding 1600 ° C without contortion or degradation. The tubes’ corrosion-resistant buildings guarantee long-lasting efficiency in hostile chemical settings. Large-diameter styles suit bulk material handling or larger samples, ideal for industrial heaters, kilns, or research laboratory heating systems. Their structural honesty minimizes contamination threats, critical for applications like crystal development or steel filtration.

Alumina ceramic crucibles excel in high-heat situations because of superior thermal shock resistance. They handle fast temperature modifications without splitting, a typical problem in steel melting or glass manufacturing. The crucibles’ chemical inertness protects against reactions with molten steels, acids, or antacid, maintaining sample purity. Reusability lowers functional costs compared to conventional quartz or metal alternatives.

Toughness and thermal conductivity work together to improve efficiency. Alumina’s high thermal conductivity ensures fast warm distribution, enhancing energy effectiveness in processes like sintering or heat therapy. This property additionally reduces thermal stress, extending part lifespan. Constant warmth management is important for accuracy jobs such as semiconductor wafer fabrication or ceramic glaze screening.

Customization options address details industrial needs. Tube dimensions, crucible shapes, and wall densities are customized to fit one-of-a-kind devices or procedure demands. This versatility sustains specialized applications in aerospace parts, nuclear gas study, or high-purity chemical synthesis. Advanced producing strategies guarantee tight resistances and smooth surface areas, minimizing wear during usage.

Quality control procedures ensure dependability. Each product undertakes rigorous testing for density, porosity, and thermal stability. These steps make certain conformity with sector standards for security and performance.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity

What makes alumina ceramic tubes and crucibles durable? Alumina ceramic is strong. It resists wear, chemicals, and high heat. These parts handle extreme temperatures up to 1800°C without cracking. Their hardness is similar to diamonds. This makes them last longer than metal or plastic alternatives.

How does thermal conductivity affect performance? Alumina ceramic transfers heat efficiently. This helps maintain stable temperatures in furnaces or labs. Fast heat spread reduces hot spots. This protects samples or materials inside. Energy use stays lower compared to materials with poor conductivity.

Can these products be customized for specific needs? Yes. Sizes, shapes, and thicknesses are adjustable. Large diameters suit industrial machinery. Small crucibles fit lab experiments. Holes, grooves, or threads are added as needed. Custom designs match exact equipment or process requirements.

Where are these tubes and crucibles commonly used? They work in labs, metal processing, and electronics. Labs use them for high-temperature experiments. Factories melt metals or alloys in crucibles. Semiconductor plants handle corrosive materials. Their heat resistance suits harsh environments.

How do I maintain alumina ceramic products? Clean them with mild detergent and soft brushes. Avoid harsh chemicals or abrasive tools. Check for cracks or chips before use. Store them in dry areas to prevent moisture damage. Proper care ensures years of reliable service.

(Custom Large-Diameter Alumina Ceramic Corundum Tube Alumina Ceramic Crucible High Durability and Thermal Conductivity)

REQUEST A QUOTE

RELATED PRODUCTS

Precision 99% alumina ceramic round rod

High Al2O3 Aluminum Oxide Alumina Ceramic Tube

Black 99% Alumina Ceramic Honeycomb Ceramic for Electric Appliance

High Temperature Resistant Aluminum Oxide Alumina Al2O3 Ceramic Crucible with Lid

High-Performance 95% Alumina Ceramic Blocks