Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

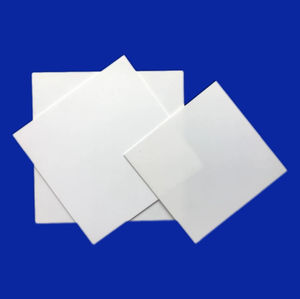

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod)

Specifications of Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod

Custom-made Whole 99% High Purity Al2O3 Alumina Porcelain Crucible Products and associated parts are created for demanding industrial applications. These products use 99% alumina content. This ensures high performance under severe problems. The product takes care of temperature levels up to 1700 ° C. It resists thermal shock. Rapid temperature adjustments create marginal stress and anxiety. The structure remains stable. Mechanical strength is superb. Alumina ceramic components endure heavy loads. They resist wear gradually. Deterioration resistance is one more essential attribute. Acids, antacid, and harsh chemicals do not damage the material. Electric insulation residential or commercial properties are strong. These parts work well in high-voltage settings.

Customization options include tubes, pipes, rods, and crucibles. Dimensions differ. Diameters vary from a few millimeters to over 500 millimeters. Lengths change based on requirements. Shapes adhere to customer specifications. Surface area surfaces are smooth. Tolerances remain tight. Accuracy machining guarantees consistency.

These ceramics serve industries such as metallurgy, chemical processing, and electronic devices. Laboratories utilize them for high-temperature experiments. Semiconductor making depends on their pureness. Metal melting processes require long lasting crucibles. Thermal handling tools utilizes alumina tubes. Electric systems benefit from protecting parts.

Product pureness issues. Higher alumina web content boosts efficiency. Pollutants are below 1%. This boosts thermal security. It enhances chemical resistance. Thickness is high. Porosity stays low. This protects against contamination. Seeping dangers lower.

Quality control actions include rigorous testing. Each batch goes through checks. Density dimensions validate standards. Purity levels confirm with X-ray analysis. Thermal shock examinations mimic real conditions. Strength assessments use mechanical lots trials. Flaws are lessened.

Personalized orders call for comprehensive specs. Clients give measurements, forms, and application demands. Production uses innovative molding and sintering. Technical assistance is readily available. Examples can be provided. Lead times rely on complexity.

These alumina ceramic items meet stringent industrial needs. Toughness makes sure long life span. Performance remains reputable under stress. Upkeep requires remain reduced. Costs reduce gradually. Performance enhances in critical procedures.

(Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod)

Applications of Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod

Customized entire 99% high-purity Al2O3 alumina ceramic crucibles, tubes, pipelines, and rods are extensively utilized in industries requiring extreme resilience and warmth resistance. These parts take care of temperatures approximately 1800 ° C, making them ideal for high-heat processes. The product’s chemical security avoids reactions with acids, antacid, and molten steels. This makes certain consistent performance in severe atmospheres.

Alumina ceramic crucibles prevail in research laboratory setups for melting and analyzing steels, alloys, and glass. Industrial furnaces use alumina tubes or pipes for thermal handling due to their low thermal growth. Semiconductor making relies upon alumina parts for wafer handling, where purity protects against contamination. Metallurgical procedures use alumina rods for mixing or delivering liquified materials.

Electric insulation buildings make alumina ceramics suitable for insulators in high-voltage systems. Use resistance extends their use to mechanical elements like seals or bearings. Personalized shapes and sizes are possible via innovative machining, conference certain devices requirements.

The 99% pureness grade enhances efficiency in precision applications. It lowers porosity, enhancing mechanical stamina and thermal shock resistance. This makes the material reputable for repeated heating and cooling cycles.

Alumina ceramic parts are affordable for lasting use. They outlast steels or plastics in severe conditions, lowering replacement prices. Minimal upkeep is needed as a result of their inert nature.

Industries like aerospace, energy, and drugs rely on alumina ceramics for important processes. They are selected for their ability to keep honesty under stress. Personalized develops make certain compatibility with specialized equipment.

High-purity alumina ceramic products are necessary where failure is not a choice. They integrate warmth resistance, chemical inertness, and mechanical toughness. This makes them a useful remedy for demanding technological applications. Modification choices permit adaptation to unique operational demands.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod

Customers often ask about Custom 99% High Purity Al2O3 Alumina Ceramic products. Here are answers to common questions.

What makes alumina ceramic materials suitable for high-temperature applications? The high purity (99% Al2O3) ensures excellent thermal stability. These materials withstand temperatures up to 1750°C. Their low thermal expansion reduces cracking risks under rapid temperature changes.

Are these ceramic parts resistant to chemical corrosion? Yes. Alumina ceramic resists acids, alkalis, and molten metals. This makes it ideal for labs or industrial processes involving corrosive substances. The non-reactive surface prevents contamination of materials inside crucibles or tubes.

How durable are alumina ceramic crucibles compared to other materials? They outperform metals or graphite in longevity. High hardness (Mohs 9) minimizes wear from abrasion. Proper handling avoids mechanical shock damage. Users report years of reliable service in frequent high-heat use.

Can custom shapes like tubes or rods be made with precise dimensions? Absolutely. Advanced sintering techniques allow tight tolerances (±0.5% on diameter or thickness). Manufacturers tailor designs to fit specific equipment. Complex geometries require detailed specifications to ensure performance matches needs.

What maintenance ensures long-term performance of alumina ceramic parts? Avoid sudden temperature shifts. Preheat crucibles gradually before reaching maximum temperatures. Clean residues with non-abrasive tools. Do not use harsh chemicals that might micro-crack the surface. Store components in dry environments to prevent moisture-related weakening.

These factors highlight the practicality of high-purity alumina ceramics in demanding settings. Users prioritize material properties, customization options, and care guidelines to maximize value.

(Custom Whole 99% High Purity Al2o3 Alumina Ceramic Crucible Materials Alumina Ceramic Part Alumina Ceramic Tube Pipe Rod)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramics Whole High Quality Industrial Ceramic Textile Ceramic Eco-friendly Winner Textile Knitting

2025 Customized Sizes New 99% Alumina Ceramic Parts

Ceramic thermocouple Protection alumina pipe

X Ray Ceramics High Voltage Al2o3 Alumina in Ceramic Metallized Ceramics Vacuum Metal Brazing

Aluminum Oxide Ceramic Basket Gemstone with Zirconia Ceramic Gravel 38.1*25*23mm