Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

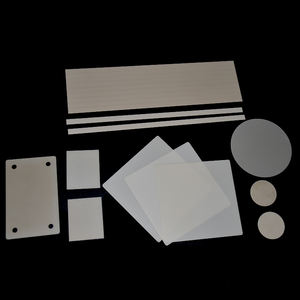

(Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts)

Specifications of Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts

Custom-made premium alumina ceramic architectural crucibles, plates, and components are created for requiring commercial applications. These elements are made from premium alumina ceramic material. The alumina web content is normally above 95%, making sure strong heat resistance and mechanical security. They manage temperature levels up to 1800 ° C without warping or splitting. Their thermal shock resistance permits rapid home heating and cooling cycles. This makes them ideal for heating system use, steel melting, and high-temperature handling.

These products are personalized in size, form, and thickness. Standard measurements range from 50mm to 500mm in diameter or length. Thickness alternatives vary between 3mm and 50mm. Facility geometries like holes, grooves, or tipped styles are sustained. Surface area surfaces can be polished, polished, or left raw based upon application requirements. Tolerance degrees are tight, generally within ± 0.5% of specified dimensions.

Alumina ceramic components withstand chemical corrosion. They function well in acidic, alkaline, or molten metal environments. Their high firmness (Hv 1500-1700) minimizes wear in unpleasant setups. Electrical insulation buildings stop existing leakage in digital furnace. Reduced thermal conductivity helps preserve energy efficiency throughout high-heat procedures.

Manufacturing makes use of sophisticated molding strategies. Dry pushing, isostatic pushing, or slip casting make certain uniform density. Components go through high-temperature sintering for optimal toughness. Quality checks include X-ray examination and ultrasonic testing. These methods identify inner defects or fractures. Each batch undertakes dimensional confirmation and tons testing.

Packaging alternatives safeguard components throughout shipping. Vacuum-sealed movies, foam inserts, or wood dog crates are readily available. Customized branding or labeling is provided for mass orders. Technical assistance covers material selection, design optimization, and usage guidelines. Examples are attended to efficiency screening prior to automation.

The products fulfill worldwide standards like ISO 9001 and RoHS. Preparations depend on complexity, ranging from 7 to thirty days. Bulk order price cuts apply for repeat clients. Maintenance suggestions consist of preventing mechanical effect and sudden temperature adjustments. Appropriate handling makes certain extended service life.

(Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts)

Applications of Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts

Customized high-grade alumina ceramic structural crucibles, plates, and components offer essential functions across sectors. These elements take care of severe conditions due to their high-temperature resistance, chemical security, and mechanical sturdiness. Their personalized layouts guarantee specific suitable for specialized devices, increasing efficiency sought after settings.

In metallurgy, alumina ceramic crucibles thaw and refine metals at temperatures surpassing 1600 ° C. They stand up to thermal shock, stopping splits throughout rapid heating or cooling. Their non-reactive nature maintains molten metals pure, avoiding contamination from the crucible product. This makes them optimal for refining precious metals or producing high-performance alloys.

Laboratories count on alumina ceramic plates and parts for experiments entailing corrosive chemicals or extreme warmth. The material doesn’t weaken when revealed to acids, alkalis, or solvents. This reliability guarantees precise test results over repeated usage. Scientists use these parts in furnaces, reactors, or analytical instruments where consistency matters.

The semiconductor industry makes use of alumina ceramic parts in producing processes. Their electrical insulation buildings stop current leakage in high-voltage equipment. They additionally stand up to plasma environments during chip production, preserving architectural integrity under hostile conditions. Custom-made shapes and sizes assist incorporate these components into complex machinery.

Aerospace applications take advantage of alumina ceramic’s lightweight yet robust features. Engine elements, thermal barrier, and sensor real estates made from this material endure severe friction and temperatures during trips. Their low thermal expansion reduces stress and anxiety under rising and fall warmth, extending component life-spans in crucial systems.

Industrial furnace utilize alumina ceramic plates as stable assistances for burner. The plates distribute heat evenly, stopping hotspots that damage furnaces or kilns. Their resistance to oxidation maintains them functional in oxygen-rich settings, decreasing maintenance expenses.

Electronics makers use alumina ceramic architectural components as insulators in gadgets like circuit breakers or power resistors. The product’s high dielectric toughness makes sure security in high-energy applications. Customized develops line up with certain gadget dimensions, boosting item performance.

Alumina ceramic parts supply cost-efficient options by lasting longer than steel or plastic alternatives in harsh settings. Their adaptability throughout fields highlights their value in modern-day industrial and technical workflows.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts

What are the customization options for alumina ceramic crucibles and plates? Custom sizes, shapes, thicknesses, and surface finishes are available. Specific features like holes, grooves, or engraved markings can be added. Designs match exact requirements for lab tools, industrial equipment, or specialized machinery. Material purity levels are adjusted based on application needs. Samples are provided for approval before mass production.

How is the quality of these alumina ceramic parts ensured? High-purity alumina powder is used for raw material. Advanced sintering techniques create dense, durable structures. Each batch undergoes strict testing for hardness, wear resistance, and thermal stability. X-ray inspection checks internal defects. Dimensional accuracy is verified with precision tools. Certifications like ISO 9001 confirm consistent manufacturing standards.

What temperatures can these crucibles and plates handle? They withstand continuous use up to 1800°C in oxidizing or inert atmospheres. Thermal shock resistance allows rapid heating or cooling within safe limits. Performance surpasses metals or plastics in extreme heat. Gradual temperature changes prevent cracks. Proper handling avoids sudden thermal stress.

What industries use customized alumina ceramic structural parts? Common applications include laboratory research, metal melting, and chemical processing. Semiconductor manufacturing relies on them for high-purity environments. Industrial furnaces use them as liners or supports. Energy sectors apply them in fuel cells or nuclear reactors. They replace traditional materials needing frequent replacement.

How should these ceramic parts be maintained for long life? Avoid dropping or hitting them against hard surfaces. Clean with mild detergents and soft brushes after cooling. Store in dry conditions to prevent moisture absorption. Check for surface wear or microcracks before reuse. Follow manufacturer guidelines for maximum thermal cycles. Proper care extends service life significantly.

(Customized Good Quality Alumina Ceramic Structural Crucibles Plates Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Porosity and Pore Diameter Alumina Porous Ceramic Disc

High Quality 95% 99 Insulator Electronic Alumina Ceramic Parts Al2o3 Sleeve Bush

High Quality Alumina Ceramic Tiles 99.9% Purity

Alumina Ceramic Tiles Can Be Used in Various Harsh Natural Environments.

High Voltage Ceramics 95% Alumina Al2o3 Metallized Ceramic Plate in Electrical and Electronic Devices Metal Brazing