Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Customized High Purity 99% Alumina Ceramic Tube)

Specifications of Customized High Purity 99% Alumina Ceramic Tube

Personalized High Purity 99% Alumina Porcelain Tube satisfies commercial requirements for dependable performance in severe problems. The product make-up ensures 99% light weight aluminum oxide material. This ensures high density, superb hardness, and superior wear resistance. The product fits applications needing thermal stability, electric insulation, or chemical inertness.

The alumina ceramic tube runs in temperatures approximately 1650 ° C. It preserves architectural stability under rapid thermal shifts. The material withstands deterioration from acids, alkalis, and molten metals. This makes it perfect for rough chemical settings. Electrical insulation properties protect against existing leak even at high voltages.

Personalized dimensions are offered to fit certain requirements. Diameter, length, and wall surface thickness can be changed based upon application needs. The tubes are compatible with precise machining for complex geometries. Surface area coatings consist of polished, glazed, or coated choices to enhance performance.

Applications cover several markets. Semiconductor manufacturing makes use of the tubes for wafer processing and heating system components. Metallurgical sectors rely upon them for thermocouple protection and molten metal handling. Laboratories use the tubes in high-temperature testing and analytical tools.

Quality assurance ensures uniformity. Each batch undergoes X-ray fluorescence evaluation to confirm purity. Density and solidity examinations confirm mechanical residential or commercial properties. Visual assessments and dimensional checks remove issues prior to shipping.

Packaging secures televisions during transportation. Foam inserts and rigid boxes stop breakage. Customized product packaging options are offered for mass orders or vulnerable styles.

Technical assistance assists with layout optimization. Designers provide support on material choice and dimensional tolerances. Samples are readily available for screening prior to major production.

The product abides by worldwide requirements for commercial porcelains. Accreditations consist of ISO 9001 for quality management. Paperwork like examination records and product security data sheets is provided.

Preparations vary based on order intricacy. Standard sizes ship within 2 weeks. Custom-made develops call for extra time for tooling and prototyping. Rush orders are fit when possible.

Customer service manages inquiries without delay. Quotations consist of pricing, specs, and distribution details. After-sales support resolves issues related to performance or compatibility.

(Customized High Purity 99% Alumina Ceramic Tube)

Applications of Customized High Purity 99% Alumina Ceramic Tube

Custom-made high purity 99% alumina ceramic tubes are extensively used throughout industries because of their one-of-a-kind homes. These tubes handle extreme problems, making them optimal for demanding applications. In commercial settings, they serve as protective sheaths for thermocouples and sensors. Their high warmth resistance enables them to operate in heating systems, kilns, and activators without degrading. They additionally withstand chemical corrosion, guaranteeing long-term reliability in extreme environments.

The electronics market relies upon these tubes for insulating elements. Their electric insulation stops current leakage in high-voltage systems. Semiconductor making utilizes them as procedure tubes during crystal growth or wafer processing. The material’s purity avoids contamination, making certain product top quality.

Medical equipment take advantage of alumina ceramic tubes’ biocompatibility. They are utilized in imaging gadgets, medical tools, and dental instruments. Their smooth surface area stands up to microbial development, meeting hygiene requirements. Sanitation processes do not harm the tubes, making them reusable.

Power industries utilize these tubes in fuel cells and batteries. They separate electrodes while permitting ion transfer, boosting effectiveness. Solar panel production utilizes them as crucibles for melting silicon. Their thermal security guarantees regular outcomes throughout high-temperature steps.

Laboratories use alumina tubes for sample handling in spectrometers and analyzers. Their non-reactive nature protects against disturbance with examination outcomes. They additionally work as liners in gas chromatography systems, maintaining precise measurements.

Aerospace and defense markets apply these tubes in sensing units and communication systems. They withstand resonances, radiation, and temperature shifts throughout missions. Their lightweight style decreases overall tools weight without giving up performance.

Customized dimensions and forms make these tubes adaptable to details needs. Makers change wall density, diameter, and length to fit distinct machinery or procedures. This flexibility ensures compatibility with varied technological needs.

High pureness alumina ceramic tubes use toughness and accuracy. Their resistance to use, heat, and chemicals reduces maintenance costs. Industries select them for vital applications where failure is not a choice.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized High Purity 99% Alumina Ceramic Tube

What is high purity 99% alumina ceramic tube used for?

These tubes are used in industrial and lab settings. They handle high temperatures, corrosive chemicals, and electrical insulation. Common uses include semiconductor manufacturing, furnace components, and protective sheaths for sensors. Their hardness and wear resistance make them suitable for mechanical parts in harsh environments.

Can dimensions and shapes be customized?

Yes. Custom sizes, lengths, and diameters are available. Tubes can be designed with specific wall thicknesses or inner/outer diameters to fit equipment. Complex shapes like flanged or tapered tubes are possible. Manufacturers adjust production based on technical drawings or samples provided.

What benefits does 99% alumina ceramic offer over other materials?

The 99% alumina content improves thermal stability and chemical resistance. It outperforms metals or plastics in extreme heat or acidic conditions. The material retains strength up to 1650°C and resists oxidation. Its electrical insulation properties prevent current leakage in high-voltage applications.

What temperature can these tubes handle?

They operate continuously at 1600-1650°C. Short-term exposure to 1750°C is possible. Exact limits depend on tube thickness and environmental factors like gas composition. Sudden temperature changes may cause cracks, so gradual heating or cooling is recommended.

How to order customized tubes?

Provide details like dimensions, quantity, and application. Manufacturers review requirements and confirm feasibility. A prototype or small batch is made for testing. After approval, full production starts. Lead times vary but typically take 2-4 weeks. Quality checks ensure tubes meet specifications before shipping.

(Customized High Purity 99% Alumina Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Aluminium Oxide C795 Alumina Ceramic Base Cap

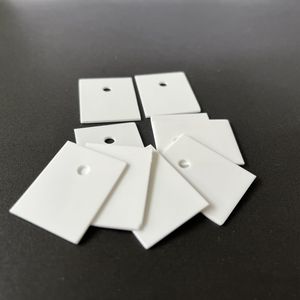

99% Alumina Ceramic Plate for Semiconductor/Medical/Electronics, High Purity, Wear Resistant, Insulating

Alumina Porous Ceramic Plates With 99 Alumina Ceramic Custom Products

Aluminium Silicate 4*8 Insulation Sheets High Alumina Ceramic Fiber Board

High Quality Whole Round Microporous Ceramic Model Alumina Ceramic Can Be Customized