Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

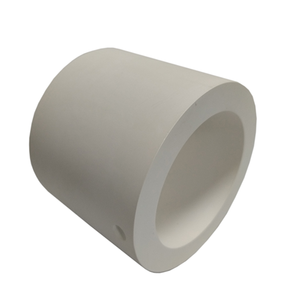

(Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube)

Specifications of Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube

Manufacturing Facility Supply Customized High Alumina Tube 99 Alumina Porcelain Sleeve Alumina Ceramic Tube meets industrial demands requiring toughness and heat resistance. The item includes 99% light weight aluminum oxide, making sure high pureness and trustworthy efficiency in severe conditions. Custom-made dimensions are readily available, including external diameters from 2mm to 200mm and lengths as much as 2000mm. Wall surface density ranges in between 1mm and 20mm, adaptable to specific job requirements.

The product endures temperatures up to 1800 ° C, ideal for heating system cellular linings, thermocouple protection, and semiconductor processing. It resists chemical rust, keeping security in acidic or alkaline atmospheres. Mechanical stamina is high, with a firmness ranking of HRA 85-90 and bending strength surpassing 300MPa. Electrical insulation properties stop current leakage, ideal for high-voltage applications.

Surface area finishes are smooth or textured, customized to decrease rubbing or improve gripping. Tolerances are tight, with size precision within ± 0.5% and straightness discrepancies under 0.1 mm per 100mm. Custom forms like arm joints, flanges, or threaded ends are producible. Televisions go through stringent high quality checks, consisting of density tests (≥ 3.8 g/cm SIX) and X-ray inspection for inner issues.

Applications extend metallurgy, aerospace, electronics, and energy industries. Usage instances include kiln furnishings, laser components, shielding rollers, and laboratory equipment. The product’s reduced thermal growth minimizes contortion throughout quick temperature level changes. Abrasion resistance extends service life in high-wear settings like conveyor systems or pump parts.

Customization options include bore dimension modifications, slots, openings, or finishings like silicon carbide for improved wear resistance. Bulk orders receive volume discount rates, with lead times in between 2-6 weeks based upon intricacy. Packaging utilizes foam-lined wooden pet crates to avoid transit damages. Technical support is offered for layout optimization and product choice.

Certifications adhere to ISO 9001 and RoHS requirements. Examples are attended to testing prior to full-blown manufacturing. Basic material are sourced from verified suppliers, ensuring uniformity across sets. Production utilizes sophisticated dry-pressing or extrusion techniques, complied with by precision sintering. Post-processing consists of grinding, polishing, or laser marking for traceability.

(Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube)

Applications of Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube

Manufacturing Facility Supply Custom-made High Alumina Tube 99 Alumina Porcelain Sleeve Alumina Ceramic Tube offers essential roles throughout industries. These components excel in high-temperature environments. They stand up to severe heat without degrading. Industrial heating systems count on them for lining or architectural support. Metallurgical procedures utilize these tubes to take care of liquified steels. The product’s thermal security makes sure minimal wear with time.

Chemical handling plants benefit from their rust resistance. Extreme acids or antacid cause little damages. Alumina ceramic sleeves shield delicate equipment in activators or pumps. Electronics producing usages these tubes as insulators. They protect against electrical leakage in high-voltage systems. Semiconductor manufacturing needs ultra-pure materials. The 99% alumina structure avoids contamination during chip fabrication.

Aerospace applications demand materials that withstand anxiety. High alumina tubes work as protective real estates for sensors in engines. Automotive systems use them in exhaust or exhaust control. They protect parts from heat and abrasion. Laboratory devices like kilns or analyzers depends on alumina sleeves for precise temperature administration.

Personalization makes sure compatibility with particular equipment. Sizes and shapes adapt to one-of-a-kind commercial requirements. The production process assurances tight tolerances. Surface surfaces minimize rubbing in relocating parts. These tubes reduce downtime by lasting longer than metal choices.

High alumina ceramic stands up to oxidation. It maintains strength in oxygen-rich environments. Electrical insulation buildings make it ideal for crossbreed applications. The material’s firmness prevents scratches or cracks. Industrial individuals save costs through decreased substitute frequency.

Manufacturing facilities focus on these tubes for integrity. They perform under conditions where plastics or steels fall short. Constant top quality satisfies global standards. Engineers trust fund alumina ceramics for essential procedures. The item’s flexibility extends from hefty sector to sophisticated tech industries.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube

What is high alumina ceramic? High alumina ceramic contains over 99% aluminum oxide. This material offers high mechanical strength, excellent wear resistance, and strong insulation properties. It performs well in extreme temperatures and harsh environments. Industries widely use it for parts requiring durability and thermal stability.

Can these alumina tubes be customized? Yes. Factories provide customization for dimensions, shapes, and technical specifications. Customers share specific requirements like inner/outer diameters, lengths, or surface finishes. Production teams adjust formulas and processes to meet these needs. Custom orders typically take 2-4 weeks depending on complexity.

What temperature can these tubes withstand? High alumina tubes handle temperatures up to 1800°C. They resist thermal shock, maintaining structural integrity during rapid heating or cooling. This makes them suitable for furnaces, kilns, or high-heat industrial equipment. Regular ceramic materials often crack under similar conditions.

Where are these alumina sleeves commonly used? They serve in metallurgy, semiconductor manufacturing, and chemical processing. Common applications include thermocouple protection, sensor insulation, or molten metal handling. Their non-reactive nature prevents contamination in labs or precision machinery. Some clients use them as protective sleeves for mechanical components exposed to abrasion.

How to maintain alumina ceramic tubes? Clean them with dry cloths or mild solvents. Avoid harsh chemicals that might damage surfaces. Inspect for cracks or chips before reuse. Store tubes in dry environments to prevent moisture absorption. Handle carefully during installation to prevent impact damage. Proper maintenance extends their lifespan significantly.

(Factory Supply Customized High Alumina Tube 99 Alumina Ceramic Sleeve Alumina Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Alumina Aluminum Oxide Ceramic Stirring Rod

Wear Resistant Alumina Ceramic Thin Sheets Zirconia Tounghness Alumina ZTA Ceramic Plate

Ceramic 95% Alumina Ceramic Insulator For Boilers And Burners

Ceramic thermocouple Protection alumina pipe

Aluminum Oxide Ceramic Basket Gemstone Coated with Zirconia Ceramic by Gravel