Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder)

Specifications of Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder

Factory Zirconia Toughened Alumina Porcelain Powder (ZTA) integrates light weight aluminum oxide (Al2O3) with zirconium dioxide (ZrO2) to develop a high-performance product. The powder is crafted for applications needing strength, use resistance, and thermal security. It is widely utilized in industrial, medical, and engineering fields.

The normal make-up ranges from 75-85% alumina (Al2O3) and 15-25% zirconia (ZrO2). This balance enhances sturdiness contrasted to pure alumina. The powder’s bit size distribution is snugly managed. The average bit dimension is 0.5-5 microns. Great particles ensure uniform sintering and thick final products.

The sintered density of ZTA ceramic components is 4.2-4.5 g/cm FIVE. High density boosts mechanical homes. The material’s hardness reaches 16-18 Grade point average on the Vickers range. This makes it appropriate for rough environments. ZTA’s crack toughness exceeds 6 MPa · m 1ST/ ² due to zirconia’s stage makeover device.

ZTA ceramic powder carries out well under high temperatures. Its optimum service temperature is 1600 ° C. Thermal shock resistance is excellent. Rapid temperature level adjustments cause minimal damage. The product’s thermal conductivity is low. This assists in thermal insulation applications.

Chemical security is one more essential feature. ZTA resists deterioration from acids, antacid, and molten metals. It remains secure in oxidizing ambiences approximately 1400 ° C. This makes it ideal for rough chemical settings.

Applications include wear-resistant linings, cutting tools, and biomedical implants. It is made use of in seals, bearings, and commercial machinery parts. The powder works with pressing, extrusion, and injection molding procedures.

Product packaging choices consist of moisture-proof secured bags. Typical packaging is 25 kg per bag. Customized dimensions are offered. The powder undertakes rigorous quality assurance. Examinations consist of XRD for phase evaluation and SEM for microstructure analysis.

Manufacturing facility ZTA ceramic powder satisfies ISO 9001 and ASTM requirements. Set consistency is guaranteed. Technical assistance is attended to custom formulations.

(Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder)

Applications of Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder

Manufacturing Facility Zirconia Toughened Alumina Porcelain Powder (ZTA Aluminum Oxide Powder Al2O3 Powder) is a high-performance material extensively utilized across markets. It integrates alumina’s hardness with zirconia’s toughness, developing a sturdy item perfect for requiring settings.

In industrial equipment, ZTA powder types parts like seals, bearings, and cutting devices. These parts encounter hefty wear, heats, or destructive chemicals. The product stands up to abrasion, keeps strength under stress and anxiety, and takes care of thermal shocks. This reduces downtime and extends devices life.

Clinical applications use ZTA powder for implants and medical devices. Its biocompatibility ensures safety and security in the human body. Hip and knee substitutes gain from its strength and put on resistance. Dental tools made with ZTA remain sharp much longer, improving precision in procedures.

Electronics making relies upon ZTA powder for insulating components and substrates. The product’s security at high temperatures stops circuit damage throughout manufacturing. It also supports miniaturization in tools by providing reputable performance in small styles.

Aerospace and vehicle fields make use of ZTA for engine parts and heat shields. The powder’s lightweight nature cuts gas consumption while dealing with extreme warm. Turbocharger parts and wind turbine blades made from ZTA withstand high-speed turnings without splitting.

Chemical processing plants use ZTA powder in pump components and valve seats. These elements stand up to acid rust and erosion from unpleasant slurries. This makes certain secure, effective handling of aggressive chemicals.

Building and construction products like drill little bits and reducing discs use ZTA powder. Its durability permits faster boring via hard surfaces. Wear-resistant tiles made with ZTA last much longer in high-traffic areas.

ZTA Light Weight Aluminum Oxide Powder is versatile. It meets rigorous criteria for toughness, durability, and integrity. Industries select it to improve product performance and lower upkeep expenses. The powder’s flexibility makes it an essential product ahead of time technology and industrial options.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder

What is ZTA ceramic powder?

ZTA ceramic powder is a mix of aluminum oxide (Al2O3) and zirconium dioxide (ZrO2). It combines high hardness from alumina with toughness from zirconia. This makes it strong and resistant to wear and heat. It is used in industrial parts needing durability under stress.

What materials are in ZTA powder?

The main materials are aluminum oxide (around 80%) and zirconium dioxide (around 20%). Sometimes small amounts of other oxides are added. The alumina gives hardness. The zirconia stops cracks from spreading. This mix balances strength and flexibility.

Why pick ZTA over regular alumina or zirconia?

Regular alumina is hard but brittle. Zirconia is tough but expensive. ZTA gives both hardness and toughness at a lower cost. It lasts longer in high-stress environments. It resists wear better than pure alumina and costs less than pure zirconia.

Where is ZTA powder used?

ZTA powder is common in making wear-resistant parts like seals, bearings, and cutting tools. It is used in mining equipment, pumps, and valves. Medical tools like joint replacements use it for strength and biocompatibility. It works in high-temperature settings like furnace parts.

How should ZTA powder be stored and handled?

Store it in a dry place away from moisture. Use sealed containers to avoid contamination. Keep temperatures below 30°C. Wear gloves and masks when handling to prevent skin contact or breathing in particles. Follow safety guidelines for ceramic powders to ensure safe use.

(Factory Zirconia Toughened Alumina Ceramic Powder ZTA Aluminum Oxide Powder Al2O3 Powder)

REQUEST A QUOTE

RELATED PRODUCTS

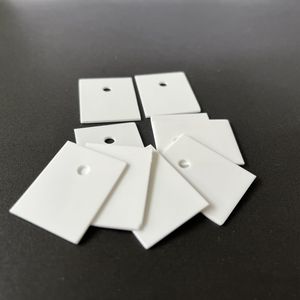

Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Substrate Ceramic Plate Zirconia Plate

Low-Sodium Calcined Alumina Electronic Ceramics Raw Material Aluminium Oxide Stable Crystal Structure Excellent Electrical

High Hardness Alumina Ceramic Parts Aluminum Oxide Chemical Stability Ceramic Shaft for Wall Mounted Boiler Pump

Aluminum Oxide Al2O3 Fine Powder for Ceramic Industry CAS 1344-28-1

Ceramic Blocks, Ceramic Insulating Bases Ceramics, 95 Porcelain Alumina Ceramics