Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

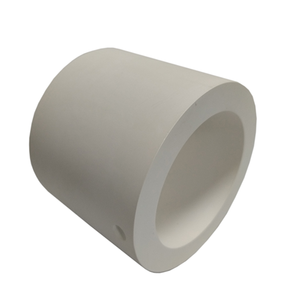

Introduction to High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger)

Specifications of High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

This alumina ceramic plunger uses high-purity aluminum oxide. It’s designed for demanding jobs needing electrical insulation. Its main job is moving smoothly inside other parts. It handles high frequencies well. This makes it perfect for electronics and electrical systems. It stops electricity from flowing where it shouldn’t. This keeps things safe and working right.

One big plus is its light weight. This puts less stress on the equipment it’s used in. That means less wear and tear. It also has high strength. It can take a lot of pressure. It won’t break easily. This toughness helps it last a long time. You get good value for your money.

The material itself is very pure. We’re talking 95% to 99.9% Al2O3. This high purity gives it excellent insulation properties. It also has high density. This stops gases or liquids from leaking through it. Its hardness is impressive. It measures around 9 on the Mohs scale. This hardness makes it resistant to getting worn down. It stands up to abrasion very well.

It handles heat very well. It can work in temperatures as high as 1700°C. It won’t melt or deform easily. It doesn’t conduct electricity. This makes it safe for high-voltage uses. It also fights off chemicals. Acids and bases generally don’t harm it. This makes it reliable in harsh environments.

The surface finish is very smooth. This minimizes friction when it moves. Less friction means less wear on itself and the parts it touches. This smoothness helps it operate efficiently. It extends the working life of the plunger and the whole assembly.

(High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger)

Applications of High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

Alumina ceramic parts are very important in many industries. They are made from aluminum oxide. This material has great electrical insulation properties. It works well for high-frequency applications. These ceramics keep signals clean. They stop electrical leaks. This is vital in radio equipment. They are also used in medical devices. Medical imaging tools need reliable insulation. Alumina ceramics handle high voltages safely. They are stable in tough conditions. Heat doesn’t bother them much. They resist wear extremely well. Their surface stays smooth. This is good for parts moving against each other.

The light-weight aluminum oxide ceramic plunger is a special part. It uses the same strong alumina material. The key point is its low weight. It is much lighter than metal plungers. Steel plungers are heavy. This ceramic plunger reduces the load. Machines using it need less power. Energy use goes down. It moves faster and easier. This improves efficiency. The plunger is very hard. It doesn’t scratch easily. It handles chemicals without damage. This makes it last a long time. It saves money on replacements.

These ceramics are ideal for demanding jobs. Semiconductor manufacturing uses them. They hold wafers during processing. High temperatures are no problem. The aerospace industry values them too. Aircraft systems need trustworthy insulation. Alumina parts deliver that reliability. They are also found in scientific instruments. Precision equipment needs stable platforms. Alumina provides that stability. The light-weight plunger is common in industrial valves. It controls flow accurately. Its low mass allows quick responses. This gives better process control.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

These ceramic plungers are made from aluminum oxide. Aluminum oxide is a special ceramic material. This material offers excellent electrical insulation. It also handles high temperatures well. These plungers are very lightweight compared to metal parts. The low weight helps in moving parts and high-speed applications. Less weight means less energy is needed to move them. This improves efficiency.

Why are these plungers so light? Aluminum oxide ceramic has a low density. Density means how heavy something is for its size. Aluminum oxide is naturally less dense than metals like steel. This makes the finished plungers much lighter. The material is strong though. It does not sacrifice strength for low weight.

These plungers insulate electricity very well. Aluminum oxide is a superb electrical insulator. It does not conduct electricity easily. This property is vital in electrical devices. It prevents unwanted current flow. It protects sensitive components. This insulation works even at high voltages.

They perform excellently at high frequencies. High-frequency signals need stable materials. Aluminum oxide ceramic has low electrical loss. It does not absorb much signal energy. Signals pass through clearly. This makes them perfect for RF applications. Think radio equipment and communication devices.

These plungers are tough and long-lasting. Aluminum oxide ceramic is very hard. It resists wear and scratches. It does not deform under pressure. The material withstands high temperatures. It does not break down easily. Chemical resistance is another plus. Harsh chemicals usually don’t damage it. This durability ensures a long service life.

(High Frequency Insulating Ceramics Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Ceramic 6mm,20mm Inert Alumina Ceramic Ball as Catalyst Support Media Ceramic Ball

High Purity 99% Factory Customized Alumina Ceramic Insulation Tube Al2O3 High Temperature Resistance for Industrial Ceramic

Manufacturing Dry Pressing Moulding 99% Al2O3 Alumina Ceramic Block Plate

Ceramic Alumina High Temperature Ceramic Alumina Tube for Furnace

High Hardness Aluminum Oxide 99% Alumina Ceramic Tube for Wear-Resistant Industry