Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

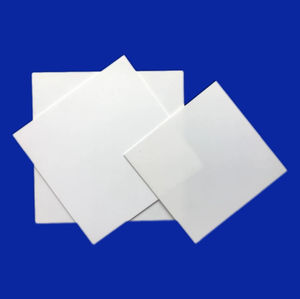

(Hot Ceramic Factory Direct Alumina Ceramic Tiles)

Specifications of Hot Ceramic Factory Direct Alumina Ceramic Tiles

Hot Ceramic Factory Direct Alumina Porcelain Tiles are designed for high-performance commercial applications. These tiles are made from premium-grade alumina ceramic material. The alumina material is over 95%, guaranteeing superb resilience and resistance to severe conditions. The product is sintered at heats, developing a dense framework that holds up against heavy wear and rough environments.

The floor tiles can be found in basic densities of 5mm, 10mm, and 20mm. Personalized densities are readily available upon request. Measurements normally vary from 50mm x 50mm to 200mm x 200mm. Larger sizes can be generated to satisfy details job requirements. Surface area coatings consist of smooth, sleek, or distinctive choices for different rubbing requirements.

These alumina tiles take care of temperatures approximately 1600 ° C without shedding structural stability. They stand up to thermal shock, making them appropriate for rapid heating or cooling down procedures. The reduced thermal development coefficient stops cracking under temperature adjustments. Chemical resistance is solid versus acids, antacid, and destructive compounds. This makes them ideal for chemical processing plants or steel smelting procedures.

Mechanical residential properties consist of high hardness, ranked 9 on the Mohs range. The floor tiles are harder than a lot of steels, lowering wear in unpleasant settings. Compressive strength goes beyond 2200 MPa, making certain lasting efficiency under hefty loads. Electric insulation properties are excellent, with high dielectric strength for use in electric systems or high-voltage locations.

Installment is uncomplicated. The tiles can be bound to steel or concrete surfaces utilizing high-temperature adhesives. They are additionally compatible with mechanical fastening approaches for added protection. Regular upkeep is marginal. Cleaning requires just water or light solvents to get rid of debris.

Warm Ceramic Manufacturing facility Straight deals competitive rates because of internal production. Quality control is rigorous, with each batch checked for thickness, firmness, and dimensional accuracy. Preparations are brief, even for custom-made orders. Bulk purchases get discount rates.

Applications consist of lining commercial tools like pipes, receptacles, and cyclones. They secure machinery in mining, power generation, and steel manufacturing. The floor tiles extend equipment lifespan and lower downtime from wear-related failings.

Client assistance assists with material choice and setup support. Technical requirements are attended to engineering testimonials. Examples are readily available to examine compatibility with details operating conditions.

(Hot Ceramic Factory Direct Alumina Ceramic Tiles)

Applications of Hot Ceramic Factory Direct Alumina Ceramic Tiles

Warm Ceramic Manufacturing Facility Direct Alumina Porcelain Shingles serve several commercial objectives. These floor tiles deal with severe conditions. They resist high temperatures, wear, and deterioration. Industries rely on them for durable performance.

One vital use remains in industrial heaters. High warmth problems routine materials. Alumina floor tiles line furnace interiors. This secures the framework. It also enhances energy effectiveness. The tiles shield well, minimizing heat loss. Factories save money on fuel prices.

Mining devices deals with heavy wear. Alumina ceramic tiles armor equipment parts. Crushers, chutes, and receptacles last longer. Rough materials like ore cause much less damages. Maintenance periods extend. Production downtime decreases.

Power plants use these ceramic tiles in central heating boilers and wind turbines. Heats stress tools. Alumina floor tiles secure important elements. They avoid erosion from ash and bits. This extends machinery life. Safety and security improves with fewer breakdowns.

The chemical industry take care of corrosive compounds. Alumina tiles layer reactors and pipes. Acids and alkalis cause less harm. Leak dangers decrease. Employees manage hazardous products a lot more securely.

Steel mills depend on alumina tiles. Molten metal calls for sturdy linings. Heating systems, ladles, and transfer systems remain shielded. Thermal shock resistance avoids fractures. Manufacturing runs smoothly without disruptions.

Cement plants use these ceramic tiles in rotating kilns. Basic material grind against surfaces. Alumina ceramic tiles minimize wear in cyclones and ducts. Dirt extraction systems function better. Devices lasts longer under severe problems.

Transportation systems benefit too. Exhaust parts encounter high warmth. Alumina tiles line exhaust manifolds. Warm stays contained. Close-by parts stay clear of damages. Gas performance improves with regulated temperature levels.

Alumina ceramic floor tiles adapt to several settings. Their hardness and thermal stability make them flexible. Industries reduced costs and enhance integrity. These tiles address troubles regular materials can not handle.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot Ceramic Factory Direct Alumina Ceramic Tiles

Hot Ceramic Factory Direct Alumina Ceramic Tiles are popular in industrial and high-temperature settings. Here are answers to common questions.

What are Alumina Ceramic Tiles used for?

These tiles protect surfaces exposed to extreme heat, wear, or chemicals. They are used in furnaces, kilns, boilers, and machinery. They also line floors or walls in factories needing durable, heat-resistant materials.

How durable are these tiles?

Alumina ceramic tiles are very hard. They resist scratches, impacts, and corrosion. They last longer than steel or plastic in harsh conditions. Their strength makes them ideal for heavy industrial use.

Can these tiles handle high temperatures?

Yes. They withstand temperatures up to 1600°C (2912°F) without cracking. The high alumina content keeps them stable in heat. They work well in furnaces, foundries, or any high-heat environment.

How do I clean and maintain them?

Clean with mild soap and water. Avoid abrasive cleaners or strong acids. Check for cracks or chips regularly. Replace damaged tiles quickly to maintain protection. Maintenance is simple due to their stain-resistant surface.

Can I get custom sizes or shapes?

Yes. Hot Ceramic Factory Direct offers custom sizing, thickness, and shapes. Provide your requirements. Production is fast. Custom tiles match specific machinery or space needs.

The answers focus on practical details. They avoid technical jargon. The goal is clarity for buyers in industries like manufacturing or construction.

(Hot Ceramic Factory Direct Alumina Ceramic Tiles)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Supply High Temperature 99% Alumina Ceramic Tube

High-Quality Zibo Ceramic Grinding Cylinders with Aluminum Oxide Composition

95% High-Purity Alumina Aluminum Oxide Ingot for Industrial Use

CNC Machining Customized High Purity 95% 99% Aluminum Oxide Al2O3 Alumina Ceramic Solid Rod

Refractory Industrial Electrical Insulation 95% Al2O3 Alumina Ceramic Tubes Aluminum Oxide Insulator