Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Industrial Ceramic Insulator 99 High Alumina Ceramic Tube)

Specifications of Industrial Ceramic Insulator 99 High Alumina Ceramic Tube

The Industrial Ceramic Insulator 99 High Alumina Ceramic Tube is designed for demanding industrial applications. The primary material is alumina (Al ₂ O SIX), with a content of 99%. This guarantees high mechanical stamina and resistance to extreme temperatures. Television runs reliably in atmospheres approximately 1700 ° C. Its thermal shock resistance enables rapid home heating or cooling cycles without cracking.

Measurements vary to meet diverse needs. Criterion lengths range from 50mm to 500mm. External sizes are readily available in between 10mm and 200mm. Wall surface density alternatives period 5mm to 30mm. Custom-made dimensions are feasible for specialized jobs. The surface area finish is smooth to reduce contamination and preserve insulation performance.

Electric insulation efficiency is remarkable. The dielectric toughness exceeds 15 kV/mm. This makes the tube appropriate for high-voltage systems. Chemical resistance covers acids, antacid, and corrosive gases. It protects against deterioration in rough commercial setups.

Applications consist of electrical power systems, furnace components, and semiconductor manufacturing. Television is made use of in kilns, reactors, and chemical handling devices. Its mechanical toughness supports heavy-duty use. The hardness degree reaches Mohs 9, minimizing wear in time.

The production procedure utilizes high-purity alumina powder. Accuracy molding and sintering at over 1600 ° C ensure density and structural stability. Quality control checks include thickness dimensions and X-ray defect discovery. Qualifications like ISO 9001 and RoHS compliance warranty dependability.

The item’s low thermal development coefficient minimizes dimensional changes under heat. This supports performance in fluctuating temperature levels. Its reduced porosity enhances resistance to infiltration by liquids or gases.

Installment is simple because of standard dimensions. Compatibility with steel fittings and seals streamlines assimilation into existing systems. Maintenance demands are minimal. Routine examinations for surface damages or contamination are suggested.

The alumina ceramic tube exceeds standard materials like porcelain or steatite. It offers longer service life and decreased downtime. Price efficiency comes from minimized substitute regularity and regular efficiency under stress and anxiety.

Adjustable alternatives include threaded ends, flanges, or internal coverings. Technical assistance is offered for design and application-specific inquiries. Mass orders consist of customized packaging to avoid transportation damages.

(Industrial Ceramic Insulator 99 High Alumina Ceramic Tube)

Applications of Industrial Ceramic Insulator 99 High Alumina Ceramic Tube

Industrial ceramic insulators made from 99 high alumina ceramic tubes are essential elements in lots of industries. These tubes are known for their stamina, warmth resistance, and electrical insulation properties. They are extensively used in electrical systems. High-voltage power transmission systems depend on these insulators to prevent energy loss. They safely different conductive components while dealing with extreme electrical anxiety.

The material’s high alumina content gives it exceptional thermal stability. Industrial heating systems and kilns use these tubes to line burner. They endure temperatures above 1500 ° C without weakening. This makes them suitable for steel processing, glass production, and ceramic production.

Chemical resistance is another vital function. The tubes do well in corrosive settings. Chemical plants use them in reactors and pipelines. They withstand acids, alkalis, and other severe substances. This expands equipment lifespan and decreases maintenance prices.

Mechanical resilience makes sure integrity popular problems. The tubes deal with heavy loads and resonances without fracturing. Mining and building and construction equipment utilize them as protective real estates or insulators. Their firmness likewise decreases wear gradually.

Modification alternatives include versatility. The tubes can be formed into poles, sleeves, or complicated geometries. This enables specific combination right into machinery. Producers change dimensions and surface area finishes to meet specific demands.

Price performance is a major benefit. The lengthy life span of high alumina ceramic tubes decreases substitute regularity. Energy cost savings originate from reliable warmth monitoring. Industries minimize functional expenses while keeping performance.

Safety renovations are substantial. The material’s non-flammable nature stops fire threats in high-temperature applications. Electrical insulation homes safeguard employees from shocks. This develops much safer workplaces in fields like energy and production.

These tubes sustain environment-friendly modern technology efforts. Their durability and energy efficiency straighten with sustainable methods. Renewable resource systems, such as solar and wind power installments, use them to boost integrity.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Ceramic Insulator 99 High Alumina Ceramic Tube

What is an Industrial Ceramic Insulator 99 High Alumina Ceramic Tube? This product is made from 99% alumina ceramic material. It is designed for high-temperature insulation in industrial settings. The tube resists heat, corrosion, and mechanical wear. It is commonly used in electrical systems, chemical plants, and metallurgical equipment.

What temperature can this ceramic tube handle? The tube works in temperatures up to 1800°C. It stays stable under extreme heat. The material expands very little when heated. This makes it suitable for furnaces, kilns, and high-heat machinery.

Where is this ceramic tube typically used? It is used as insulation in power transmission systems. It lines chemical reactors to prevent corrosion. It protects components in semiconductor manufacturing. It is also applied in metal smelting and glass production.

Why choose this over other insulating materials? The 99% alumina content improves thermal resistance. It has higher mechanical strength than lower-grade ceramics. It lasts longer under stress compared to plastic or rubber insulators.

Can the tube be customized for specific needs? Yes. Manufacturers adjust dimensions like length, diameter, and wall thickness. Custom shapes are possible for unique applications. Provide details to the supplier for tailored solutions.

(Industrial Ceramic Insulator 99 High Alumina Ceramic Tube)

REQUEST A QUOTE

RELATED PRODUCTS

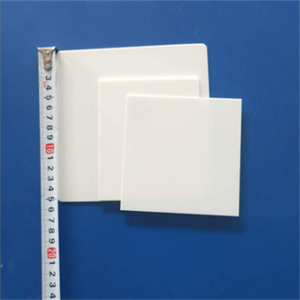

High Purity 95 96 99 Aluminum Oxde Alumina Ceramic Block Al2o3 Ceramic Tile Ceramic Thick Plate

Aluminum Oxide Lining Plate as Chute Liner

Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

X Ray Ceramics High Voltage Al2o3 Alumina in Ceramic Metallized Ceramics Vacuum Metal Brazing

Wear Resistance 99 Alumina Ceramic Tube Porcelain Insulators For