Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

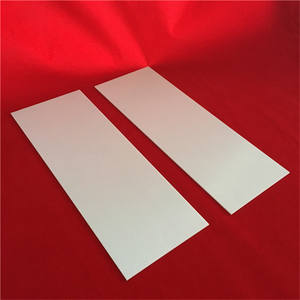

(Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate)

Specifications of Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate

The Industrial Heat Immune 96% Aluminium Oxide Alumina Ceramic Plate is developed for high-temperature applications. It has 96% aluminum oxide, guaranteeing solid thermal stability. The remaining 4% consists of trace ingredients to boost efficiency. This plate stands up to temperature levels as much as 1700 ° C without warping or losing strength. It stands up to thermal shock, making it ideal for rapid heating or cooling down settings. The product has a density of 3.6 g/cm THREE, giving an equilibrium between light-weight layout and sturdiness. Its high firmness level (Hv 1500) ensures resistance to use and abrasion. The flexural toughness is 300 MPa, allowing it to handle hefty mechanical anxiety. The compression strength reaches 2200 MPa, optimal for load-bearing applications. The low thermal expansion coefficient (8.0 x 10 ⁻⁶/ ° C) decreases size changes under warmth. Thermal conductivity is 25 W/m · K, enabling effective heat circulation. Home plate runs successfully in harsh or oxidizing ambiences. It withstands chemical attack from acids and alkalis, preserving stability in extreme conditions. Electric insulation residential or commercial properties continue to be stable at high temperatures, preventing current leak. The surface coating is smooth, lowering rubbing and fragment generation. Requirement density varies from 1mm to 50mm, with personalized sizes available. Common measurements consist of 100x100mm, 200x200mm, and 300x300mm. Larger or irregular forms can be generated based upon demands. The ceramic plate works with machining processes like drilling or grinding for exact suitable. Applications include furnace cellular linings, kiln furniture, and warm therapy tools. It offers in metal processing, glass production, and semiconductor production. The product is used for insulating components in electric systems and protective guards in high-heat zones. Custom-made configurations suit particular commercial requirements. Evaluating consists of checks for splits, porosity, and dimensional accuracy. Quality control guarantees each plate meets sector requirements. Product packaging makes use of protective materials to prevent damage during delivery. Lead times differ depending on order dimension and customization. Bulk orders get affordable pricing. Technical support is available for product selection and use guidelines. The ceramic plate uses long service life with very little upkeep. Efficiency remains regular under continuous high-temperature exposure. It replaces standard materials like metal alloys in extreme atmospheres. Compatibility with commercial equipment streamlines integration into existing systems.

(Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate)

Applications of Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate

Industrial heat-resistant 96% aluminum oxide alumina ceramic plates are commonly utilized in high-temperature environments. These plates take care of extreme warm up to 1600 ° C without losing stamina. Their high thermal security makes them optimal for heating system cellular linings, kiln furnishings, and heat treatment tools. They avoid warm damage in industrial arrangements, guaranteeing long-lasting efficiency.

These ceramic plates withstand chemical rust, also in extreme problems. Acids, alkalis, and molten metals do not conveniently harm them. This makes them ideal for chemical handling tools, steel smelting, and glass production. They protect machinery from harsh substances, lowering maintenance prices.

The product’s electric insulation homes are important in electronic devices and power systems. It protects elements in high-voltage environments, stopping electric failures. It is made use of in breaker, insulators, and semiconductor manufacturing tools. The plates make sure security and dependability in electrical applications.

Mechanical toughness is an additional essential function. Home plates withstand hefty lots and rough wear. They are used in mining, cement manufacturing, and steel mills as wear-resistant liners. Their durability expands equipment life, cutting downtime and substitute prices.

In automotive and aerospace sectors, the ceramic plates act as heat shields. They protect sensitive components from exhaust warmth and burning temperature levels. Their light-weight nature enhances fuel effectiveness without jeopardizing safety and security. They are additionally used in welding components, making sure specific part positioning during high-heat procedures.

Food and pharmaceutical industries use these plates for sanitary, non-reactive surfaces. They fulfill rigorous cleanliness standards in processing tools. The product does not infect items, ensuring safe production atmospheres.

Alumina ceramic plates are cost-effective for thermal administration in energy systems. They line central heating boilers, reactors, and heat exchangers, enhancing energy effectiveness. Their reduced thermal conductivity minimizes warm loss, saving power in commercial processes.

Custom shapes and sizes are readily available for particular requirements. Home plates are machined to fit devices layouts, providing versatility throughout sectors. Easy setup and compatibility with existing systems make them a functional selection for upgrades or brand-new projects. Their versatility and dependability make them essential in contemporary industrial applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate

What is the maximum temperature the industrial heat-resistant 96% aluminium oxide ceramic plate can handle? The plate withstands temperatures up to 1700°C. Its high alumina content ensures stability in extreme heat. This makes it suitable for furnaces, kilns, and high-temperature industrial processes.

What industries commonly use this ceramic plate? It is widely used in manufacturing, metal processing, and aerospace. Electronics and chemical plants also rely on it. The material’s heat resistance and electrical insulation properties protect equipment.

How durable is the alumina ceramic plate compared to other materials? The plate is harder than steel and resists wear. It outperforms metals and plastics in harsh environments. Chemical corrosion and abrasion have minimal impact. This extends the service life of components.

Can the ceramic plate be cleaned or maintained easily? Cleaning requires only mild detergent and water. Avoid abrasive tools or harsh chemicals. The surface stays smooth and non-porous. Regular inspections for cracks or chips help maintain performance.

Are custom sizes or shapes available for specific applications? Yes. Manufacturers offer tailored dimensions and thicknesses. Custom shapes like tubes or discs can be produced. Specifications depend on project requirements. Contact suppliers directly for detailed options.

(Industrial Heat Resistant 96% Aluminium Oxide Alumina Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

New Product Factory Alumina Ceramic Tube Alumina Ceramic Tubes High Temperature Alumina Tube

Customized Alumina Ceramic Part High Temperature Resistant Industrial Ceramic Part

Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

Wear Resisting Alumina Ceramic Parts Aluminum Oxide Corrosion Resistance Ceramic Shaft for High Speed Pump

Supply Wear-Resistant Ceramic Pipes Aluminum Oxide Ceramic Lined Elbow Complete Specifications