Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

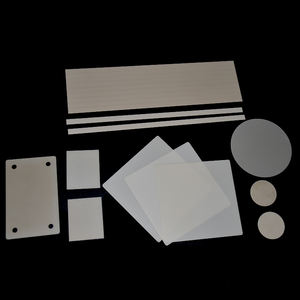

Description

Introduction to Innovative Catalyst Support Aluminum Oxide Microspheres

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Innovative Catalyst Support Aluminum Oxide Microspheres

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Innovative Catalyst Support Aluminum Oxide Microspheres)

Specifications of Innovative Catalyst Support Aluminum Oxide Microspheres

These innovative catalyst support aluminum oxide microspheres offer a superior platform. They are engineered for high performance in demanding applications. The microspheres feature a highly controlled size distribution. This ensures uniform packing and consistent flow characteristics. A large specific surface area is critical. These spheres provide plenty of space for active catalyst material. This maximizes the catalyst’s effectiveness.

The pore structure is carefully designed. It features a specific pore volume and adjustable pore size. This allows precise control over catalyst loading. It also helps molecules move easily to the active sites. The aluminum oxide material is chemically inert. It resists reactions with process chemicals. This stability protects the catalyst’s activity over time.

Thermal stability is another key advantage. These microspheres withstand high temperatures without breaking down. They maintain their structure even under severe heat. This durability ensures long-term reliability. Mechanical strength is also impressive. The spheres resist crushing and abrasion. They endure the physical stresses inside reactors.

These properties make the microspheres ideal supports. They work well for many catalytic processes. Industries like petrochemicals and refining benefit greatly. The design optimizes catalyst efficiency. It also extends the catalyst’s useful lifespan.

(Innovative Catalyst Support Aluminum Oxide Microspheres)

Applications of Innovative Catalyst Support Aluminum Oxide Microspheres

Innovative catalyst support aluminum oxide microspheres are tiny, round particles made from aluminum oxide. They act as a strong base for catalysts in many industries. Their special shape and material offer big advantages. These microspheres provide a large surface area. This is crucial for catalysts. It lets more reactions happen at once. The particles are also very stable. They handle tough conditions well.

One key use is in oil and gas refining. They support catalysts that crack heavy oil into lighter fuels like gasoline. The microspheres help the catalyst last longer. This improves efficiency. It also reduces costs for refineries. Chemical makers rely on them too. They are essential for making basic chemicals and plastics. The microspheres ensure reactions run smoothly and reliably. This leads to better quality products.

Environmental applications are important. These microspheres support catalysts in devices that clean exhaust gases. Cars and factories use these devices. The catalysts convert harmful pollutants into safer substances. The microspheres’ durability is vital here. They withstand high temperatures and corrosive gases. This keeps the cleaning systems working effectively.

The pharmaceutical industry uses them. They support catalysts for creating complex drug molecules. The precise shape of the microspheres helps control these sensitive reactions. Fine chemical production also benefits. Makers of special chemicals need reliable catalysts. The microspheres deliver consistent performance batch after batch. This supports high-purity production.

These aluminum oxide microspheres improve catalyst performance overall. They make processes more efficient. They help achieve higher product yields. Industries gain a dependable tool for critical chemical reactions. The unique properties of these microspheres solve common catalyst support problems. They offer a robust solution for demanding applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Innovative Catalyst Support Aluminum Oxide Microspheres

What are Innovative Catalyst Support Aluminum Oxide Microspheres?

These are tiny, round particles made from aluminum oxide. They are designed to hold catalyst materials. They give the catalyst a stable place to sit. This helps chemical reactions happen better.

Why use these microspheres?

They offer several big advantages. They have a very large surface area. This means more catalyst can be attached. More catalyst usually means faster or better reactions. They are also very strong and resist heat well. They won’t break down easily under tough conditions. Their perfectly round shape and consistent size are important too. This helps chemicals flow evenly around the catalyst. This improves the reaction’s efficiency.

Where are these microspheres used?

You find them in many industries needing catalysts. They are common in oil refining and making chemicals. They help make fuels and other products. They are also used in making medicines and creating new materials. Any process needing a strong, reliable support for a catalyst might use them.

Are these microspheres safe?

Yes, they are generally safe when handled correctly. Aluminum oxide is a stable, inert material. It doesn’t easily react with other substances. You still need to follow standard safety rules. Wear gloves and a mask when handling fine powders. Avoid breathing in the dust. Store them properly to prevent spills.

How do I handle and store them?

Handle them gently to avoid breaking them. Store them in a cool, dry place. Keep them away from strong acids or bases. Keep the container sealed tight. This stops moisture or dirt from getting in. Follow any special instructions from the supplier.

(Innovative Catalyst Support Aluminum Oxide Microspheres)

REQUEST A QUOTE

RELATED PRODUCTS

OEM Polished Aluminum Oxide Wire Guides & Alumina/Zirconia Eyelets

Ceramic Fillers: Aluminum Oxide Powder

High Temperature Chemical Industrial 92 95 Al2o3 High Alumina Ceramic Plate

Alumina Ceramic Parts Aluminum Oxide Refractory Ceramic Shaft for Pumps

Heat Resistance Technical High Purity Aluminum Oxide Ceramic Setter Plates