Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod)

Specifications of Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod

The Mirror Refined OD5mm 99% Alumina Ceramic Shaft Pole is created for high-performance applications needing precision and longevity. The rod features an external size of 5mm, making sure compatibility with components in limited spaces. It is made from 99% alumina ceramic, a material understood for exceptional solidity and resistance to use. The surface area is mirror-polished to reduce friction and boost operational smoothness in relocating components.

This ceramic shaft rod masters environments subjected to severe temperatures. It keeps structural integrity from -50 ° C to 500 ° C, making it suitable for commercial heating systems or cryogenic tools. The material resists chemical rust, ensuring reliability in acidic or alkaline conditions. Electrical insulation buildings protect against existing leakage, ideal for digital or high-voltage devices.

High dimensional precision is attained through advanced sintering and grinding procedures. The pole’s straightness resistance is firmly regulated to lessen resonance during high-speed turnings. Its low thermal growth coefficient makes certain security under fast temperature changes. This decreases the risk of contortion or fracturing popular applications.

The alumina ceramic structure offers a Vickers firmness of over 1500 HV, exceeding several metals and polymers. This solidity extends service life in unpleasant settings. The rod’s light-weight nature decreases inertia in rotating systems, boosting power efficiency. It is compatible with vacuum atmospheres, avoiding outgassing dangers usual with organic materials.

Normal applications include precision equipment, medical gadgets, semiconductor manufacturing, and aerospace components. The pole serves as a reputable alternative to steel shafts in scenarios requiring electric isolation or rust resistance. Its smooth surface area coating minimizes endure bearings or seals, decreasing maintenance prices.

The item is made under strict quality controls to guarantee uniformity. Each set undertakes extensive screening for thickness, surface finish, and mechanical stamina. Custom lengths are available to fulfill certain task requirements. The rod is packaged securely to avoid damages throughout shipping.

This alumina ceramic shaft rod meets sector criteria for high-performance design materials. It attends to usual challenges like thermal stress, chemical degradation, and electrical dangers. Customers benefit from minimized downtime and longer periods between substitutes. The mix of accuracy design and robust material residential properties makes it a functional option for sophisticated technological systems.

(Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod)

Applications of Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod

The mirror-polished OD5mm 99% alumina ceramic shaft rod is a high-performance component utilized in markets calling for accuracy and sturdiness. Its smooth surface area and limited dimensional accuracy make it excellent for applications where rubbing reduction and security matter. The material’s high pureness guarantees exceptional mechanical stamina, chemical resistance, and thermal security.

These rods are generally utilized in semiconductor manufacturing. They handle harsh chemicals and high temperatures throughout wafer handling. Their non-reactive nature protects against contamination, making certain tidy manufacturing environments.

Medical gadgets likewise take advantage of alumina ceramic shaft poles. They are made use of in medical tools and analysis tools. The product’s biocompatibility meets stringent health criteria. It withstands duplicated sanitation without deteriorating.

Accuracy tools like evaluates and sensors count on these poles. Their wear resistance preserves precision with time. The low thermal growth maintains measurements steady under temperature level modifications.

Optical systems use these rods for positioning parts. The refined surface reduces light scattering. This enhances efficiency in lasers and imaging gadgets.

High-temperature commercial processes use alumina ceramic rods as heater elements. They stand up to thermal shock and maintain architectural integrity above 1500 ° C. This minimizes downtime popular settings.

Automotive sensors include these poles for dependable procedure. They protect against electrical disturbance while enduring engine warm and resonance. This enhances sensing unit durability and information precision.

The rods are additionally used in fabric machinery. Their firmness decreases wear in high-speed spinning and weaving. This decreases maintenance expenses and expands tools life.

Lab tools uses these rods for sample handling and testing. Chemical inertness makes sure results remain uncontaminated. The smooth surface avoids sample bond.

Food processing machinery employs alumina ceramic rods in mixers and conveyors. The material fulfills food-grade safety criteria. It withstands abrasion from ingredients without influencing taste or quality.

These rods offer in aerospace applications for navigation systems. Their lightweight nature and stability under stress enhance efficiency in critical elements.

The adaptability of mirror-polished alumina ceramic shaft poles makes them essential across industries. Their mix of strength, precision, and dependability addresses difficulties in innovative manufacturing and technology.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod

What is a mirror polished OD5mm 99% alumina ceramic shaft rod? This rod is a high-performance industrial component made from 99% pure aluminum oxide. It has a 5mm outer diameter. The surface is mirror-polished for a smooth finish. This reduces friction during operation. It is ideal for precision applications requiring durability and minimal wear.

Why choose alumina ceramic for a shaft rod? Alumina ceramic offers exceptional hardness. It resists wear better than metals or plastics. The material handles extreme temperatures without deforming. It does not react with chemicals. This makes it suitable for harsh environments. The mirror polish further enhances performance by lowering surface roughness.

Can this rod handle high temperatures? Yes. Alumina ceramic withstands temperatures up to 1600°C. It maintains strength and shape under thermal stress. This makes it reliable in furnaces, engines, or high-heat machinery. Unlike metals, it does not oxidize or corrode when heated.

Where is this shaft rod commonly used? It is used in precision equipment like pumps, bearings, or sensors. The medical industry uses it for devices needing sterile, non-reactive parts. Electronics manufacturers apply it in insulating components. Its smooth surface prevents contamination in cleanroom settings. Any application needing a tough, heat-resistant rod benefits from this product.

How do I maintain the alumina ceramic shaft rod? Handle it carefully during installation. Avoid impacts or sudden force. Alumina ceramic is hard but brittle. Clean it with mild detergent and a soft cloth. Do not use abrasive materials. Check for surface damage regularly. Replace the rod if cracks or chips appear. Proper care ensures long service life.

(Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod)

REQUEST A QUOTE

RELATED PRODUCTS

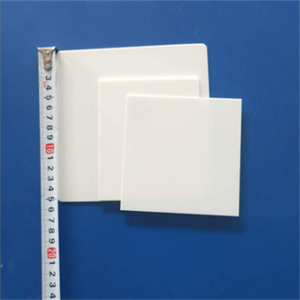

China Factory High Temperature 95 99 Aluminum Oxide Ceramic Sheet

Al2O3 Alumina Ceramic Tube Pipe

Customized 99% 95% Alumina Textile Ceramics

High Temperature Resistance Alumina Ceramic Plate

Customizable High Temperature Alumina Ceramic Tube Wear-Resistant Ceramic Parts for Manufacturing Include Cutting Welding