Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

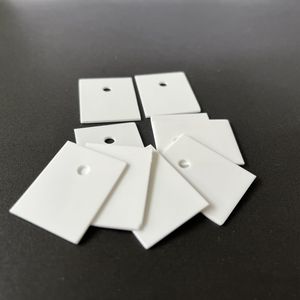

Description

Introduction to Alumina Ceramics

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Alumina Ceramics

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Provide Good high purity alumina Ceramic products in China)

Specifications of Provide Good high purity alumina Ceramic products in China

China creates high-purity alumina ceramic products fulfilling rigorous industrial requirements. These porcelains include over 99.5% aluminum oxide (Al ₂ O SIX), making certain marginal pollutants. The materials go through innovative processing techniques like sintering and precision molding. This assures constant density over 3.9 g/cm TWO, boosting sturdiness in rough environments.

High-purity alumina porcelains show extraordinary firmness, ranked at 9 on the Mohs range. This makes them resistant to abrasion and mechanical wear. The products maintain security at temperatures approximately 1700 ° C. Thermal shock resistance stops fracturing during rapid temperature level adjustments. Electric insulation residential or commercial properties continue to be reputable also under high voltage, appropriate for electronic parts.

Surface finishes differ from brightened to matte, tailored to application demands. Tight dimensional tolerances ( ± 0.1 mm or lower) make sure compatibility with accuracy devices. Criterion forms include tubes, plates, rods, and personalized geometries. Machining alternatives like laser cutting or grinding adjust items to certain layouts.

Chemical inertness permits usage in harsh settings, consisting of acids and antacids. The porcelains display low porosity (

(Provide Good high purity alumina Ceramic products in China)

Applications of Provide Good high purity alumina Ceramic products in China

High pureness alumina ceramic items play a crucial function in China’s advanced manufacturing and innovation fields. These materials are known for their outstanding firmness, warmth resistance, and electrical insulation residential or commercial properties. They are widely utilized across industries to boost performance and durability.

In electronic devices, high pureness alumina porcelains are important for semiconductor manufacturing. They serve as substrates and insulators in integrated circuits. Their capability to stand up to heats makes sure secure operation in digital gadgets. LED lighting systems also rely on these porcelains for warm dissipation. This expands the life-span of lights items.

The auto sector gain from alumina porcelains in sensing units and battery elements. Electric lorries make use of these ceramics in lithium-ion battery separators. They boost safety and security by preventing brief circuits. Engine parts made from alumina ceramics manage extreme warmth. This reduces wear and enhances gas performance.

Clinical applications include dental implants and medical tools. The biocompatibility of high pureness alumina makes it secure for usage in prosthetics. Its resistance to rust makes sure lasting integrity in clinical atmospheres. Equipment like MRI machines uses ceramic parts for precision and insulation.

Power production utilizes alumina ceramics in photovoltaic panels and atomic power plants. They serve as protective finishes for photovoltaic cells. This enhances effectiveness by reducing power loss. In nuclear centers, ceramics supply shielding versus radiation. Their security under rough problems supports safe energy generation.

Industrial machinery relies on alumina porcelains for cutting tools and wear-resistant parts. Mining equipment utilizes ceramic finishings to reduce abrasion. This decreases upkeep costs and extends machinery life. High-temperature furnaces make use of alumina components for thermal insulation. This ensures regular performance in metal handling.

China’s concentrate on advancement drives need for high purity alumina porcelains. Research continues to expand their use in aerospace and defense. These ceramics are vital for elements subjected to extreme settings. Their flexibility makes them crucial for progressing modern technology throughout fields.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Provide Good high purity alumina Ceramic products in China

What is high purity alumina ceramic?

High purity alumina ceramic is a material made from aluminum oxide. It has over 99.5% purity. This makes it resistant to heat, wear, and chemicals. It works well in extreme conditions. Common uses include electronics, industrial machinery, and medical devices.

Why choose China for high purity alumina ceramic products?

China has advanced manufacturing technology. Production costs are lower here. Many factories specialize in high-purity ceramics. They meet strict global standards. Buyers get reliable quality at competitive prices. Industries worldwide trust Chinese suppliers for consistent performance.

What industries use high purity alumina ceramics?

These ceramics are used in electronics for insulating parts. Medical fields use them for implants and tools. Industrial applications include cutting tools and seals. Aerospace and automotive sectors rely on them for engine components. Energy companies use them in sensors and batteries.

How do you ensure product quality?

Suppliers follow strict quality control steps. Raw materials are tested for purity. Production uses precision equipment. Finished products undergo checks for density and strength. Many factories have ISO certifications. Third-party labs verify performance data. Buyers can request test reports before purchasing.

Can high purity alumina ceramics be customized?

Yes. Manufacturers adjust size, shape, and surface finish. Custom designs meet specific project needs. Engineers help optimize performance for unique applications. Small batches or large orders are possible. Lead times vary based on complexity. Samples are available for testing.

(Provide Good high purity alumina Ceramic products in China)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramics 99 Porcelain Porous Bearing Plate High Temperature Resistant Ceramic Porous Industrial Ceramics

Original XEBEC G Series 1004/1006/1010/D3 Whole Ceramic Alumina Fiber Mold Metal Polishing Stone

Refractory Insulation 99% Alumina Aluminum Oxide Ceramic Disc Disk Dish

Industrial Catalyst Carrier 10mm 13mm 16mmHollow Perforated Porous Alumina Ceramic Balls

Alumina Ceramic Balls 65% Al2O3 High Temp Resistance for Industrial Furnaces-Heat & Cool Storage