Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill)

Specifications of Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

These grinding rounds utilize high-grade aluminum oxide ceramic. They can be found in three pureness degrees: 75%, 80%, and 99% Al2O3. This makes them very hard. Firmness is vital for grinding effectiveness. They crush materials efficiently. This lowers grinding time. Energy usage goes down too.

Thickness is an additional vital factor. These balls have high mass thickness. They supply solid influence pressure. This pressure breaks down tough products. High density likewise implies much less wear. The spheres last much longer. You conserve money on substitutes.

Chemical inertness is a major advantage. The high alumina material makes these rounds inert. They resist chemical assault. This is critical for grinding delicate materials. Your item remains pure. No contamination takes place. This is vital in sectors like porcelains or chemicals.

Heat resistance is exceptional. These are refractory ceramic spheres. They deal with high temperatures. Ball mill procedures frequently get hot. These rounds won’t soften or weaken. Efficiency remains consistent. This makes sure trustworthy operation.

The rounds are developed for round mills. They hold up against continuous impact and abrasion. Put on prices are reduced. Grinding effectiveness remains high with time. Maintenance periods get longer. Downtime lowers. This boosts your total productivity.

Select the purity based upon your needs. The 75% and 80% Al2O3 rounds offer excellent efficiency. They are cost-effective for lots of general grinding tasks. The 99% Al2O3 rounds supply leading efficiency. They are for requiring applications. Extreme firmness and optimum chemical resistance are needed there.

These alumina rounds are a wise option. They enhance grinding outcomes. They cut running costs. They ensure product pureness.

(Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill)

Applications of Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

These alumina ceramic rounds serve grinding tasks in round mills. They are available in various purity qualities. The 75%, 80%, and 99% Al2O3 degrees are common. High light weight aluminum oxide makes them incredibly hard. They resist use exceptionally well. This durability is important for grinding rough products. Mills run longer without requiring brand-new grinding media. Downtime reduces substantially. Production expenses often drop.

These rounds handle high temperatures easily. They are refractory materials. Warm processing environments will not damage them. This makes them perfect for industries like cement making. Mineral handling plants rely on them greatly. Ceramic makers use them too. They grind raw materials into fine powders constantly.

The 99% pureness balls are unique. They have very few impurities. This matters for sensitive applications. Contamination risks are really low. Electronics manufacturing demands this pureness. Semiconductor products need ultra-clean grinding. Advanced ceramics demand high-purity media. These balls supply reputable results.

The 80% and 75% Al2O3 spheres are workhorses. They use superb worth for many standard jobs. Grinding minerals utilizes them often. Handling ores is a typical application. Making paints and layers requires regular grinding. These rounds give trustworthy efficiency. Their solidity makes sure efficient product malfunction. They are a cost-effective selection for requiring procedures.

All these balls share crucial advantages. They are chemically inert. This means they will not respond with a lot of products being ground. Grinding procedures remain foreseeable. Item quality stays high. Their density contributes to reliable impact grinding. They move power efficiently inside the mill. Particle size decrease happens properly.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill

What are these ceramic balls made of?

These grinding balls are mainly aluminum oxide. We call it Al203. Different grades exist. You see 75%, 80%, and 99%. This number shows the alumina purity. Higher purity means better performance. The balls are fired very hot. This makes them hard and inert. They won’t react with most materials.

Why do density levels differ?

Density changes with the alumina content. More alumina means higher density. A 99% ball is denser than a 75% ball. Density matters for grinding. Higher density means harder balls. Harder balls last longer. They also grind material more efficiently.

How well do they resist wear?

Wear resistance is excellent. It gets better with higher alumina. The 99% balls wear the slowest. They are much harder than steel balls. This hardness fights abrasion. You get less ball consumption over time. Less wear means lower running costs.

Can I use these in wet grinding?

Yes, these balls work well wet or dry. The high alumina makes them inert. They won’t absorb water. They won’t react with slurry chemicals. Their structure stays stable. This makes them reliable for wet milling processes.

Are they cost-effective?

Initially, they cost more than steel. But they save money long term. Their extreme hardness makes them last much longer. You replace them less often. You also need less energy. Grinding efficiency is better. You save on maintenance and downtime too.

(Refractory 75% 80% 99% Inert Al203 Grinding High Aluminum Oxide Ceramic Ball for Ball Mill)

REQUEST A QUOTE

RELATED PRODUCTS

Zirconia Ceramic Basket Gemstone with Aluminum Oxide Touch by Gravel

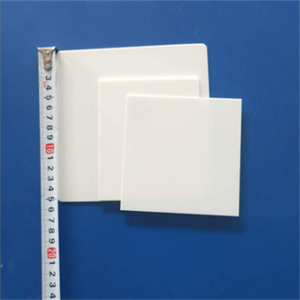

China Factory High Temperature 95 99 Aluminum Oxide Ceramic Sheet

Whole Hot High Temperature Ceramic Resistance 99% Alumina Al2o3 Ceramic Tile Hexagonal Square Silicone Carbide Tiles 10mm

Alumina Ceramic Wafer Excellent Electrical Al2O3 Insulation Disc Aluminum Oxide Disc

Round 96 99.6 Aluminum Oxide Substrate Alumina Al2O3 Ceramic Wafer