Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder)

Specifications of Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder

This alumina powder delivers high thermal conductivity. That matters for effective heat management. The powder particles are near-spherical in shape. Their size range is very fine, from 1 to 50 microns. This small size helps achieve excellent packing density. Good packing density means less empty space in your material. That boosts thermal performance significantly.

Near-spherical particles flow much better than irregular shapes. Better flow makes handling and processing easier. It allows for more uniform mixtures too. You get consistent results every time. The fine particle size increases the total surface area available. More surface area promotes better heat transfer. Heat moves efficiently through the material.

The powder is pure aluminum oxide. High purity ensures reliable performance. It minimizes unwanted reactions. This alumina powder works well in thermal interface materials. Think thermal pastes and pads. It suits heat sinks and electronic packaging too. It integrates easily into composites needing better heat dissipation. Ceramics and plastics often use it for this reason.

Its fine size and shape let it fill gaps effectively. This creates smoother thermal pathways. Heat moves away from hot spots faster. The powder disperses well in liquids and polymers. This prevents clumping. You get a smooth, even distribution. That consistency is crucial for thermal management applications. Use it where efficient heat spreading is vital.

(Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder)

Applications of Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder

This alumina powder handles heat well. It moves heat quickly. The powder particles look almost like tiny balls. This shape helps them pack together tightly. That packing boosts heat transfer. Particle sizes range from 1 to 50 microns. You can pick the size needed for your job.

One big use is in electronics. Heat can ruin electronic parts. This powder helps pull heat away. It protects sensitive components. It works inside thermal management materials. These materials keep devices cooler. It helps stop overheating. That makes devices last longer.

It also fits into heat sinks. Heat sinks pull heat from processors. Adding this powder makes them work better. The powder carries heat faster. This improves cooling performance. Devices run more reliably.

LED lights get hot too. This powder helps manage that heat. It goes into LED thermal pastes. These pastes move heat from the LED chip. Keeping LEDs cool stops them from fading. It helps them shine longer and brighter.

The powder strengthens thermal interface materials. These materials fill gaps between parts. They help heat move between surfaces. Adding this powder makes them more effective. Heat flows easier. That improves overall cooling.

It works well in industrial coatings. These coatings protect surfaces. They can also manage heat. Adding the powder gives the coating heat-spreading ability. That shields parts from high temperatures.

Composites benefit from it too. Mixing it into plastics or resins adds heat paths. The composite can then move heat. This creates lighter parts. These parts still handle thermal stress.

The powder is chemically stable. It doesn’t react easily. That makes it safe for many settings. It works in harsh conditions. It offers a practical way to boost thermal performance.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder

What makes this alumina powder special? This alumina powder transfers heat very well. This high thermal conductivity is key. It moves heat away from hot spots efficiently. This is crucial in electronics. It prevents overheating.

What particle size is it? The powder ranges from 1 to 50 microns. This is a fine powder. Different sizes suit different needs. Smaller particles can pack densely. Larger ones might flow easier. You choose the size fitting your application.

Why is the shape important? The powder particles are near-spherical. This shape is important. It allows the particles to roll smoothly. They pack together more evenly. This creates better contact points. Better contact improves heat transfer. It also makes mixing into materials simpler.

Where is this powder typically used? Its main use is in thermal interface materials. Think thermal pads or pastes. These materials fill gaps between hot components and coolers. The alumina powder boosts their heat transfer ability. It is also used in specialized plastics or ceramics needing good thermal management.

Is this powder safe? Alumina is a stable ceramic material. It is chemically inert. It does not react easily. It handles high temperatures well. It is non-toxic. Always follow standard safety procedures when handling fine powders. Wear a mask to avoid breathing it in.

(Supply High Thermal Conductivity Alumina 1-50 Micron Near-Spherical Aluminum Oxide/Alumina Powder)

REQUEST A QUOTE

RELATED PRODUCTS

Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod Zirconia Ceramic Pipe

Zirconia Ceramic Basket Gemstone with Aluminum Oxide Touch by Gravel

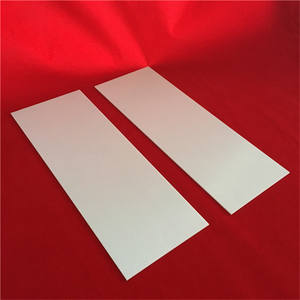

Custom Corundum Wear-resistant Alumina Ceramic Piece Al2O3 Ceramic Sheets

Aluminum Oxide Micro Grinding Media High-Alumina Ceramic Ball for Grinding

99 Ceramic Machining Parts 95 96 99 99.8 Al2O3 Alumina Ceramic