Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush)

Specifications of Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush

Technical ceramic lined tubing features a strong steel outer pipe. Inside sits a precision alumina ceramic liner. The liner comes in three purity grades: 95%, 96%, and 99% aluminum oxide (Al2O3). This Al2O3 material is extremely hard. It offers outstanding resistance to abrasive wear. Wear is a major problem in many industries. This tubing solves it effectively.

The ceramic liner surface is very smooth. This smoothness minimizes friction. Material flows easier inside the pipe. Less energy is needed to pump materials. Blockages happen less often. The ceramic bonds tightly to the steel. This prevents the liner from loosening. It ensures reliable performance under tough conditions.

Key properties define this tubing. Extreme hardness is the top feature. Alumina ceramic is much harder than steel. It resists scratching and gouging from abrasive particles. The material withstands very high temperatures. It performs well in hot environments. Chemical resistance is excellent. The ceramic handles many corrosive substances. It doesn’t rust like metal. Impact resistance is also good. The steel shell provides strong support.

The 99% Al2O3 liner offers the best performance. It is the hardest grade. It provides the highest wear resistance. It lasts the longest in severe service. The 95% and 96% grades are very good too. They are cost-effective for many applications. They still outperform standard steel pipes massively.

This tubing is ideal for moving abrasive materials. Examples include fly ash, coal dust, sand, gravel, ores, and cement. It protects pneumatic conveying lines. It lines chutes and hoppers. It works well in mining, power plants, cement production, and steel mills. It extends equipment life significantly. It reduces costly downtime for replacements. Maintenance costs go down.

(Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush)

Applications of Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush

Technical ceramic lined tubing protects pipes and parts from wear. Aluminum oxide linings at 95%, 96%, and 99% purity are very hard. This hardness fights abrasion effectively. These ceramic tubes, sleeves, and bushes last much longer than steel alone. This saves money over time.

Mining and material handling use them heavily. They line slurry pipes carrying ore, sand, or ash. Abrasive particles wear down steel quickly. The ceramic lining shields the pipe. Transfer points like chutes and hoppers get ceramic sleeves. These points see heavy impact and sliding wear. Ceramic parts resist this damage. Cyclones and classifiers in processing plants use ceramic liners. These units handle high-speed abrasive flows constantly.

Power plants depend on these ceramics too. Coal-fired plants use them in ash handling systems. Ash pipelines and fly ash hoppers need ceramic sleeves. Burner pipes and nozzles benefit from ceramic bushes. The extreme heat and particle erosion demand durable materials. Hydrocyclones in flue gas desulfurization systems use ceramic liners. The harsh slurry environment wears out metal fast.

Cement factories face similar challenges. Raw material and cement powder transport pipes require ceramic lining. The powder acts like sandpaper inside pipes. Equipment like clinker coolers and separators install ceramic wear parts. These components endure constant abrasion at high temperatures.

Oil and gas operations use ceramic tubing downhole. Tools for drilling and well intervention face sand erosion. Ceramic sleeves protect critical components. Valves controlling abrasive flows use ceramic bushes. This extends valve life significantly.

Chemical processing plants handle corrosive and abrasive mixes. Pump casings and pipe sections lined with alumina ceramic resist both. The ceramic is chemically inert and hard. This dual resistance is valuable.

Higher alumina purity (99%) offers maximum hardness and wear resistance. It costs more. 95% and 96% alumina provide excellent protection at a lower cost. The choice depends on the specific wear conditions and budget. The result is less downtime and lower replacement costs. Operations run smoother and more efficiently.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush

Here are five common questions about our Technical Ceramic Lined Tubing made with 95%, 96%, or 99% Aluminum Oxide (Al2O3 Alumina):

What is ceramic lined tubing? This tubing has a steel outer pipe. Inside is a tightly fitted liner. The liner is made from hard alumina ceramic. This protects the pipe from wear. It makes the pipe last much longer in tough conditions.

Why use Aluminum Oxide (Alumina) ceramic? Alumina ceramic is extremely hard. Hardness fights abrasion. This material resists wear better than steel alone. Alumina ceramic resists chemicals. It handles acids well. Bases too. It also stands up to high temperatures. This makes it perfect for punishing jobs.

What’s the difference between 95%, 96%, and 99% Al2O3? The number shows the alumina purity. Higher purity means better performance. 99% Al2O3 offers the top hardness. It gives the best wear and corrosion resistance. It costs more. 95% and 96% Al2O3 are strong performers. They offer great value. They handle many demanding applications well. Choose based on your specific wear needs and budget.

How is the ceramic sleeve installed? The ceramic sleeve fits tightly inside the steel pipe. Special methods ensure a secure bond. Common methods include vulcanizing with rubber. Shrinking the steel pipe onto the ceramic is another way. Mechanical locking is also used. This prevents the liner from moving or spinning. The liner stays firmly in place during use.

Where is this tubing typically used? This tubing excels wherever pipes face severe abrasion. Mining operations use it for moving ore slurry. Power plants use it in ash handling systems. Cement plants transport raw materials and clinker with it. Steel mills convey metal powders and granules. Anywhere fast-flowing, abrasive materials wear out steel pipes quickly, this ceramic-lined solution extends life significantly.

(Technical Ceramic Lined Tubing 95% 96% 99% Aluminum Oxide Al2O3 Alumina Ceramic Tube / Sleeve / Bush)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Luminous Parts Alumina High Temperature Insulation Mold Ceramic Custom Alumina Ceramic Parts

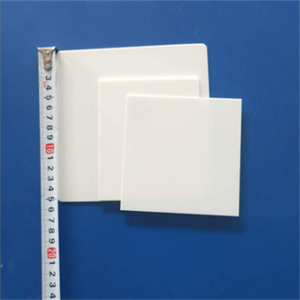

Batch Customized High-Precision Advanced 95% Al2O3 Alumina Aluminum Oxide Ceramic Lining

Alumina Ceramic Tiles Can Be Used in Various Harsh Natural Environments.

Bare Aluminum Oxide Substrate 96% Al2O3 Alumina Ceramic PCB Sheet

Manufacturing Dry Pressing Moulding 99% Al2O3 Alumina Ceramic Block Plate