Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment)

Specifications of Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment

Pink aluminum oxide is a strong abrasive material. It works well for surface preparation. It handles metal and wood surfaces effectively. This material is very durable. It lasts longer than many other abrasives. Pink aluminum oxide stays sharp longer. This means consistent performance over time. It cuts surfaces efficiently without wearing down quickly. The grit sizes available are numerous. You can find coarse grits for heavy stock removal. Fine grits are also available for finishing work. This covers a wide range of surface needs.

The particles fracture in a controlled way. They break to create new sharp edges. This maintains the cutting ability. The grit stays sharp throughout its use. Pink aluminum oxide is very hard. Its hardness level is high. This hardness allows it to work on tough materials. It cuts steel effectively. It also works well on hardwoods. The material is chemically inert. It does not react with the surface being treated. This prevents staining or contamination. It is safe for various metals and woods.

This abrasive is versatile. You can use it on belt sanders. It works on disc sanders too. Orbital sanders benefit from it. Hand sanding blocks can use it. Pink aluminum oxide is perfect for stripping paint. It removes rust effectively. It cleans surfaces thoroughly. It prepares surfaces for painting or coating. The abrasive creates a uniform surface profile. This profile helps coatings adhere better. The finish quality improves significantly. It reduces the need for rework. Pink aluminum oxide performs consistently. Users see reliable results every time. It makes surface preparation easier and faster. It saves time on projects. It reduces material costs over time. This abrasive is a practical choice for professionals.

(Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment)

Applications of Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment

Pink aluminum oxide is a top choice for surface preparation. It works great on both metal and wood. This material is very hard and sharp. It cuts surfaces efficiently. You get a consistent finish every time. It lasts long too. That saves money over time.

For metal work, pink aluminum oxide shines. It blasts away rust, old paint, and mill scale effectively. It leaves metal clean and ready for coating. This grit creates a perfect profile for paint or other finishes to stick well. It works on steel, iron, and other metals. It handles tough jobs without breaking down fast.

Woodworkers also rely on this abrasive. It smooths rough wood surfaces beautifully. It prepares wood for staining or sealing. You can achieve a fine, even texture. It removes imperfections without damaging the good wood underneath. It’s good for furniture, decks, and other wood projects.

Pink aluminum oxide is very reliable. Its uniform shape and size give predictable results. You won’t get uneven spots or damage. It cuts quickly but also lasts longer than other abrasives. This means less downtime for changing media. It produces less dust too. That makes for a cleaner workspace. Operators find it easier to control the blasting process. It’s a practical choice for many workshops.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment

People often have questions about using pink aluminum oxide for surface prep. We answer the top five.

What is pink aluminum oxide? Pink aluminum oxide is a very hard abrasive grain. It is man-made. People use it for blasting surfaces clean. It is tougher than many other abrasives. This toughness makes it last longer.

Why pick pink aluminum oxide over other abrasives? Its hardness is the main reason. Pink aluminum oxide cuts fast. It removes rust, paint, and old coatings quickly. It lasts much longer than softer abrasives. You use less material over time. This saves money. It gives a consistent finish every time.

What surfaces can I treat with it? This abrasive works great on metal. It is perfect for stripping rust and paint from steel. It prepares metal for new coatings. It also works well on hardwoods. It cleans wood without digging too deep. It smooths the surface for staining or sealing.

How does it help with wood preparation? Pink aluminum oxide cleans wood surfaces gently. It removes dirt and old finishes. It opens the wood grain slightly. This helps new stains absorb better. It creates a smooth, even base. Your finish looks better and lasts longer.

How do I use pink aluminum oxide for blasting? You need a blasting cabinet or pressure pot. Load the abrasive into your blasting machine. Adjust the air pressure. Higher pressure cuts faster. Lower pressure is gentler. Aim the nozzle at the surface. Keep it moving. This avoids digging pits. Wear safety goggles and a respirator. Good dust control is important.

(Transform Surface Preparation Processes with Reliable Pink Aluminum Oxide for Effective Metal and Wood Treatment)

REQUEST A QUOTE

RELATED PRODUCTS

Industry Calcined Polishing Aluminum Oxide for Refractory Material, CAS1344-28-1

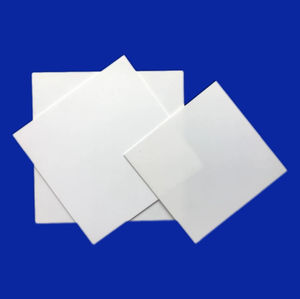

Aluminum Oxide Alumina Ceramic Setter Plate For Sintering Cathodes And Electrolytes

Factory Customized Refractory Aluminum Oxide Alumina Ceramic Substrate / Plate / Sheet / Disc

High Precision Alumina Ceramic Parts Light-Weight Aluminum Oxide Ceramic Plunger

Catalyst Material Aluminum Oxide Micro Powder