Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

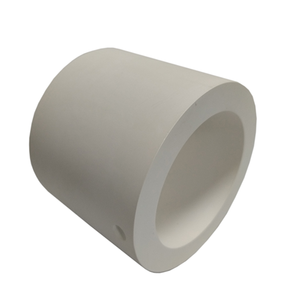

Introduction to Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

Alumina ceramics are known for their high hardness, wear resistance, corrosion resistance, good electrical insulation and high temperature stability. According to the different alumina content, it can be divided into different grades, such as 95 porcelain, 99 porcelain, etc., among which 99 porcelain refers to ceramic materials with an alumina content of 99%. As the alumina content increases, its mechanical strength and electrical insulation properties will also increase accordingly.

Characteristics of Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

High Hardness: Alumina ceramics have extremely high hardness, which makes it very wear-resistant and suitable for manufacturing abrasive tools and parts that require wear resistance.

Wear resistance: Due to its high hardness, alumina ceramics show excellent wear resistance and are suitable for manufacturing parts for long-term use.

Corrosion resistance: Alumina ceramics have good resistance to most acids and alkalis, making them widely used in the chemical industry.

Good electrical insulation: As an excellent electrical insulating material, alumina ceramics are widely used in electronic and electrical products.

High temperature stability: Ability to withstand extremely high temperatures without significant physical or chemical changes, which makes it an ideal choice for applications in high temperature environments.

Biocompatibility: In the medical field, certain grades of alumina ceramics are used to make medical devices such as artificial joints due to their good biocompatibility.

(Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment)

Specifications of Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

These alumina ceramic rods are created electroplating devices. They are developed from high-purity aluminum oxide ceramic. This product is very tough. It resists wear incredibly well. Electroplating usages extremely severe chemical bathrooms. These chemicals assault many materials. Alumina ceramic take on these acids and bases. It does not rust or rust like metal parts. Steel shafts can pollute layering baths. Ceramic rods keep the bath option pure. This makes certain consistent, top quality plating outcomes.

The surface area of these rods is extremely smooth. This smoothness protects against sticking. Layered product does not easily develop on the shaft. This decreases cleaning time. It likewise lowers upkeep costs. The rods handle heats quickly. Electroplating procedures commonly obtain very hot. Alumina ceramic keeps steady. Its measurements do not alter with heat. This keeps your process exact.

These poles offer excellent electrical insulation. They do not perform electrical power. This is vital in electroplating containers. It protects against unwanted electrical paths. It aids manage the layering existing specifically. You get better plating density control. The poles are really strong mechanically. They resist bending pressures well. They handle the physical demands inside plating equipments.

Typical sizes are offered. Typical diameters vary from 3mm to 20mm. Standard sizes are between 100mm and 500mm. Custom sizes are often possible. The alumina web content is high, normally 95% or 99%. Greater purity means far better efficiency. The firmness is very high, comparable to sapphire. Surface surface is critical. It is polished to a fine grade. This lessens friction and sticking. The rods await installment. They fit basic electroplating maker arrangements. Utilizing them enhances bathroom life and layering top quality. They are a trustworthy, lasting component.

(Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment)

Applications of Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

Alumina ceramic poles deliver genuine advantages in difficult electroplating arrangements. Electroplating bathrooms use very strong acids and bases. These chemicals rapidly damage metal components. Alumina ceramic withstands rust extremely well. It handles sulfuric acid, hydrochloric acid, chromic acid, and sodium hydroxide bathrooms. This resistance indicates the poles last a lot longer. Metal shelfs and fixtures need frequent replacement. Ceramic poles supply a long lasting remedy.

Electrical insulation is another crucial advantage. Electroplating depends on controlled electrical currents. Any kind of stray present reasons plating flaws. Metal parts carry out electrical energy quickly. This produces unwanted electrical courses. Alumina ceramic is a fantastic electrical insulator. It protects against electrical shorts entirely. Layering existing circulations just where planned. This enhances layering quality and uniformity. Issues like burnt down payments or bad attachment decline.

Mechanical toughness issues also. Alumina ceramic poles are very hard and rigid. They stand up to flexing and put on under lots. Electroplating lines relocate components continuously. Fixtures and racks experience physical tension. Ceramic poles keep their form and setting. They do not warp or bend like some plastics. This dimensional stability makes sure components remain effectively placed in the bath. Regular part placement implies consistent plating density.

Heats prevail in layering procedures. Some baths run hot. Drying ovens perform at high heat. Alumina ceramic manages extreme temperature levels quickly. It will not soften or deteriorate like plastic choices. This thermal security is crucial for trusted procedure. The poles do well from room temperature level approximately extremely high levels.

Making use of alumina ceramic shafts lowers upkeep considerably. They don’t corrode. They don’t conduct roaming currents. They stay solid under lots. They tolerate warmth. This reduces downtime and substitute expenses. Production effectiveness improves. Plating high quality comes to be a lot more dependable. Consider alumina ceramic poles for your electroplating racks and components. They solve usual plating troubles successfully.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment

People often ask about alumina ceramic rods for electroplating. What are they? They are rods made from nearly pure aluminum oxide. They are very hard and tough. They handle extreme conditions well. They are used inside electroplating tanks.

Why use them in electroplating? Electroplating tanks have harsh chemicals. These chemicals attack many materials. Alumina ceramic rods resist this attack. They do not corrode or break down. They keep the plating solution clean. Metal parts cannot contaminate the bath. This makes the plating process better. Plating quality improves.

What makes them special? Their chemical resistance is key. Acids and bases do not harm them. They are very hard. They resist wear and scratching. They handle high temperatures easily. They are excellent electrical insulators. Current flows only where you want it.

How long do they last? They last a very long time. They are much tougher than plastic or metal alternatives. They withstand constant chemical exposure. They endure physical wear. They tolerate high heat. This durability saves money. You replace rods less often. Downtime decreases.

Are there different sizes? Yes. Manufacturers offer various diameters and lengths. You can get custom sizes too. Think about your specific tank setup. Consider the parts you need to hold. The right size ensures secure mounting. It provides proper electrical isolation. Choose the dimensions that fit your equipment.

(Whole Alumina Ceramic Rod Aluminum Oxide Ceramic Shaft for Electroplating Equipment)

REQUEST A QUOTE

RELATED PRODUCTS

Inert Porcelain Aluminum Oxide 99% High Alumina Ceramic Ball

Customized High Purity 99% Al2O3 Flat Bottom Crucible Alumina Ceramic Cup for Refractory Industry

Factory High Hardness Alumina Ceramic Parts Aluminum Oxide Chemical Stability Ceramic Shaft

96% 99.6% Al2O3 Ceramic Substrate Ultra Thin Aluminum Oxide Alumina Sheet

Mirror Polished OD5mm 99% Alumina Ceramic Shaft Rod