Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive)

Specification of 1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive

This item is 1-3um high-purity ceramic boron carbide powder made for usage as a wear-resistant material additive. It is used advanced synthesis modern technology to guarantee consistent high quality. The powder has a purity degree of 99.5% or higher, with low oxygen and nitrogen web content, making it perfect for requiring industrial applications. Particle dimension distribution is tightly managed in between 1 and 3 micrometers, permitting uniform mixing right into composite materials.

Boron carbide is recognized for severe hardness, ranking third after ruby and cubic boron nitride. This property enhances the resilience of elements subjected to rubbing, abrasion, or high-stress problems. The powder’s high thermal security makes sure efficiency stays consistent even at raised temperature levels up to 2200 ° C. It withstands chemical rust, making it ideal for rough atmospheres like chemical processing or metalworking.

Key applications consist of wear-resistant coatings, cutting tools, and unpleasant media. It is used in industries such as aerospace, automobile, and mining to extend equipment life-span. When added to porcelains, metals, or polymers, it significantly boosts surface area solidity and lowers wear prices. The material is also valued in shield systems as a result of its light-weight nature and ballistic resistance.

The powder is packaged in moisture-proof containers to avoid clumping. Storage space referrals include maintaining it in a completely dry, great atmosphere away from direct sunlight. Handling calls for typical industrial precaution, consisting of handwear covers and masks to avoid breathing. Personalized bit dimension adjustments are offered for certain customer needs. Mass orders can be refined with versatile distribution timetables.

This boron carbide powder goes through strenuous quality testing, consisting of X-ray diffraction and electron microscopy, to verify purity and fragment uniformity. It adheres to international product security criteria. Technical assistance is offered to assist with integration right into manufacturing processes. Samples are offered for examining compatibility with existing systems.

The item is compatible with many typical manufacturing approaches, consisting of sintering, warm pushing, and thermal splashing. Its reduced impurity profile minimizes issues in finished products. Customers report improved performance in high-wear applications, reducing downtime and maintenance expenses.

(1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive)

Applications of 1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive

1-3um high-purity ceramic boron carbide powder acts as an essential additive in wear-resistant products. Its ultra-fine fragment size makes sure even distribution within composite matrices. This enhances product toughness under extreme rubbing. Industries like automotive production use it to enhance engine components. Parts such as pistons and cylinder linings last longer. This reduces upkeep costs gradually.

The aerospace sector relies upon boron carbide for high-stress applications. Wind turbine blades face constant abrasion from debris. Adding boron carbide expands their functional life-span. It likewise preserves structural integrity at elevated temperatures. This is essential for security in aeronautics systems.

Mining devices operates in severe settings. Drill little bits and crushers encounter abrasive rocks daily. Mixing boron carbide right into these tools avoids quick wear. It keeps equipment efficient throughout prolonged use. Production downtime reduces. This boosts overall performance in mining procedures.

Cutting devices call for sharp sides to work efficiently. Boron carbide enhances the solidity of device coverings. Blades stay sharper longer. This is useful for accuracy machining in metalworking. Manufacturing facilities save cash by lowering device replacement frequency.

Industrial equipment components like seals and bearings benefit from boron carbide additives. Rubbing in between relocating parts generates warm. The material’s thermal stability decreases wear. It likewise resists chemical rust. This is essential in chemical processing plants.

Ceramic finishes with boron carbide shield surface areas in heavy machinery. Excavators and excavators deal with constant dirt abrasion. The layers function as a guard. They keep equipment performance in construction tasks.

The powder’s high purity guarantees regular performance. Contaminations might damage composite products. Rigorous quality control throughout production guarantees dependability. Manufacturers trust it for crucial applications.

Boron carbide is economical compared to alternatives like ruby powder. It offers comparable solidity at a lower price. This makes it obtainable for large commercial usage. Its lightweight nature includes value. Hefty equipment does not end up being excessively cumbersome.

Research study remains to expand its applications. New composite solutions incorporate boron carbide for specialized requirements. The product adapts to progressing sector demands. It continues to be a leading option for wear-resistant options.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive

What is ceramic boron carbide powder used for? Ceramic boron carbide powder serves as a wear-resistant additive. It strengthens materials exposed to friction, heat, or abrasion. Common applications include industrial machinery parts, armor plating, cutting tools, and nozzles. It improves durability in extreme conditions.

Why is the 1-3um particle size important? The 1-3um range balances surface area and flowability. Smaller particles integrate smoothly into base materials. This ensures even distribution during mixing. The size enhances bonding with metals or ceramics. It prevents clumping while maximizing wear resistance.

How does high purity affect performance? High purity (99%+) minimizes impurities like oxygen or metals. Contaminants weaken material integrity. Pure boron carbide resists oxidation and chemical corrosion. This extends component lifespan under stress. It maintains stability at temperatures up to 2,200°C.

Is this powder safe to handle? Direct contact requires precautions. Wear gloves, masks, and goggles. Inhalation risks lung irritation. Store it in dry, sealed containers away from moisture. Process it in ventilated areas. Follow standard ceramic powder safety protocols.

Can it blend with other materials? It combines well with metals, polymers, and ceramics. Common blends include aluminum composites for lightweight armor or epoxy coatings for abrasion protection. Test compatibility first. Adjust mixing ratios based on desired hardness and application needs.

(1-3um High Purity Ceramic Boron Carbide Powder for Wear-resistant Material Additive)

REQUEST A QUOTE

RELATED PRODUCTS

Boron Carbide Plate B4c square Ceramic

Customized High Strength Hexagonal Boron Carbide Ceramic Tiles B4C Plate

High Purity 99% Nanoparticle Boron Carbide Powder 500nm Ceramic Powder B4C Semiconductor Material Boron Carbide Powder

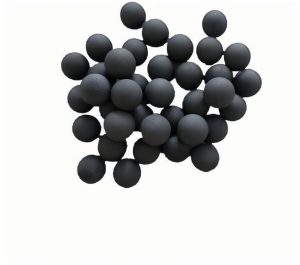

High Purity B4C Boron Carbide Ceramic Grinding Balls

High Temperature Resistant B4C Nozzle Boron Carbide Ceramic Bushing