Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction of Boron Carbide Ceramics

Boron carbide ceramics is an inorganic, non-metallic material with carbon and boron as its main components, and its chemical formula is B4C. Since its discovery in the early 20th century, this material has attracted a great deal of attention because of its unique physical and chemical properties. Boron carbide ceramics have an extremely high hardness, second only to diamond and cubic boron nitride, which makes it important in the field of wear-resistant materials. It also exhibits excellent corrosion resistance, high-temperature stability and low-density properties, attributes that make it ideal for the manufacture of bullet-proof vests, nozzles, bearings and other mechanical components that require high wear resistance. Boron carbide ceramics can also be prepared in a variety of shapes and sizes through different processes to meet the needs of different industries.

Characteristics of Boron Carbide Ceramics

Boron carbide ceramics are known for their excellent performance characteristics, starting with their ultra-high hardness and strength, which makes them resistant to severe abrasion and scratching, making them ideal for use in cutting tools and abrasives. Secondly, the material possesses excellent chemical stability and is less likely to react with chemicals such as acids and alkalis, even in extreme environments, making it widely used in certain key components in the chemical industry. In addition, the superior thermal stability of boron carbide ceramics and their ability to maintain structural and property stability at extremely high temperatures makes them one of the key materials in the aerospace and nuclear industries. Finally, it is worth mentioning its lightweight properties, which, due to its low density, make boron carbide ceramics an ideal option for application scenarios that require light weight but high strength. Together, these characteristics give boron carbide ceramics a wide range of applications.

(Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle)

Specification of Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle

The Personalized High Firmness Boron Carbide Ceramic Tubes B4C Nozzle is developed for demanding commercial applications. This product makes use of boron carbide (B4C), a material understood for extreme solidity and wear resistance. It performs well in abrasive atmospheres. The nozzle matches high-pressure systems, sandblasting, waterjet cutting, and precision machinery.

Boron carbide ceramic ranks amongst the hardest products globally, second only to diamond. This residential property makes sure extended life span under extreme problems. The tubing withstands put on well, decreasing regular substitutes. It preserves structural stability in temperature levels as much as 600 ° C. Chemical security avoids rust from acids, antacid, and various other responsive materials.

Technical specifications include a density of 2.52 g/cm five and a Vickers firmness exceeding 30 Grade point average. Personalization alternatives cover internal diameters from 0.5 mm to 50 mm, outer sizes approximately 100 mm, and lengths customized to customer demands. Resistances remain within ± 0.05 mm for accuracy. Surface area finishes can be changed for details circulation requirements.

The nozzle exceeds options like tungsten carbide or alumina. It provides superior solidity and lighter weight. This decreases energy consumption in high-speed procedures. Compatibility with automated systems allows smooth integration into existing setups. Marginal maintenance is required as a result of reduced friction and non-reactivity.

Industries such as aerospace, mining, and producing gain from this item. It takes care of rough media like silicon carbide, alumina powders, and metallic slurries. Applications extend to fuel injection systems, protective finishes, and wear-resistant elements.

Customization includes string kinds, installing configurations, and connection adapters. Clients supply specifications for customized services. Manufacturing utilizes innovative sintering techniques to guarantee uniformity. Quality checks include density examinations, hardness verification, and leak-proof analyses.

The boron carbide nozzle integrates toughness with precision. It fulfills strict standards for industrial tools. Individuals report lowered downtime and boosted functional performance. The item is readily available in standard and custom designs. Delivery times differ based upon intricacy.

Ecological resistance makes it appropriate for extreme settings. It runs dependably in moist, high-temperature, or chemically hostile environments. The material’s safe nature lines up with safety and security regulations. Cost-effectiveness stems from lasting efficiency in spite of greater preliminary investment.

Setup standards advise correct positioning and torque setups. Compatibility consult system pressures and media types are advised. Technical support aids with assimilation obstacles. Examples are readily available for testing before bulk orders.

(Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle)

Applications of Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle

Custom-made high-hardness boron carbide ceramic tubes B4C nozzles are developed for demanding commercial settings. Boron carbide attracts attention as one of the hardest products readily available. It resists wear far better than a lot of metals and ceramics. This makes B4C nozzles excellent for applications where abrasion is a constant difficulty. Industries like sandblasting depend on these nozzles. They take care of high-speed abrasive fragments without degrading swiftly. The extensive life span lowers downtime for substitutes.

In waterjet reducing systems, B4C nozzles supply accuracy. Their hardness preserves constant jet stream precision. This makes sure clean cuts in metals, stone, and compounds. Wear resistance maintains performance secure over extended periods. Manufacturing costs drop because of less component adjustments.

Mining and oil boring procedures utilize these nozzles in tools subjected to rough problems. Boron carbide endures erosion from slurry blends and high-pressure liquids. Tools durability improves. Upkeep intervals stretch additionally. Productivity acquires follow.

The aerospace market gain from B4C’s thermal stability. Nozzles in rocket propulsion systems face severe warmth and stress. Boron carbide keeps structural honesty under such anxiety. Safety and security and integrity boost.

Modification is an essential attribute. Shapes and sizes adjust to details machinery requirements. Threading, bore sizes, and mounting configurations match one-of-a-kind setups. Compatibility across devices and systems simplifies integration.

Chemical processing plants make use of B4C nozzles for destructive liquid handling. Boron carbide stands up to acids and antacids. Deterioration reduces also in hostile atmospheres. Functional uniformity remains high.

These nozzles call for marginal maintenance. Their toughness lowers lasting expenses. Power effectiveness improves as used nozzles no longer create stress decreases or leakages. Efficiency remains steady.

B4C ceramic tubes matches high-wear applications past nozzles. Safety linings, put on plates, and precision elements use this material. Adaptability meets diverse commercial needs. Personalized solutions address niche difficulties.

The mix of solidity, corrosion resistance, and thermal properties makes boron carbide a leading option. Industries focus on effectiveness and integrity. B4C nozzles provide both.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle

What is boron carbide ceramic tubing B4C nozzle?

Boron carbide ceramic tubing B4C nozzle is a high-performance component made from boron carbide. This material is extremely hard, ranking third after diamond and cubic boron nitride. The nozzle resists wear, corrosion, and high temperatures. It is used in industries requiring precise abrasive applications, like sandblasting or waterjet cutting. Customization allows tailored dimensions and shapes to fit specific machinery or processes.

Why choose boron carbide over other materials?

Boron carbide outperforms metals and other ceramics in hardness and durability. It lasts longer in abrasive environments compared to tungsten carbide or alumina. The material maintains structural integrity under extreme stress. This reduces downtime for replacements. Cost savings over time offset the higher initial price.

Can the nozzle be customized for unique needs?

Yes. Customization includes varying inner/outer diameters, lengths, and thread types. Special shapes or coatings are available for specific applications. Engineers work with clients to adjust designs based on pressure requirements or flow rates. Precision grinding ensures tight tolerances for consistent performance.

What industries use boron carbide nozzles?

These nozzles are common in sandblasting, waterjet cutting, and spray coatings. They suit oil and gas, aerospace, and military sectors. Applications involve handling abrasive media, high-speed fluids, or corrosive substances. Their reliability in harsh conditions makes them ideal for heavy machinery and precision tools.

How to maintain boron carbide nozzles?

Regular inspection for wear or cracks is critical. Clean the nozzle after use to prevent buildup. Avoid impacts or sudden temperature changes. Replace the nozzle if performance drops, like reduced pressure or uneven spray. Proper storage in dry conditions extends lifespan.

(Customized High Hardness Boron Carbide Ceramic Tubing B4C Nozzle)

REQUEST A QUOTE

RELATED PRODUCTS

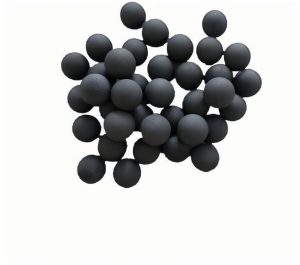

High Purity B4C Boron Carbide Ceramic Grinding Balls

2024 Industrial Grade Ceramics Plate Boron Carbide Powder F60-F1200 Refractory Material Boron Carbide B4c for Steel Plate

Black Diamond Hexagonal Shaped Boron Carbide Ceramic Tile B4C Plate

High Hardness Boron Carbide Ceramic Plate B4C Board Sheet

Multi-curved Plate B4C Boron Carbide Ceramic