Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic)

Specification of Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

This boron nitride ceramic handles extreme warm. It’s made for hard industrial work requiring custom parts. We shape it precisely just how you require. Complex layouts are feasible. This material holds up against temperatures over 1800 ° C in air. It goes even higher in inert gases or vacuum. Thermal shock is not a problem. Sudden temperature adjustments won’t break it. Its toughness stays strong when things get hot.

Warm relocations with it well. This ceramic transfers thermal energy effectively. It maintains warm moving where you need it. Electric insulation is exceptional. Current will not go through even at optimal temperature levels. This is essential for many electric applications.

Chemical resistance is solid. A lot of molten metals will not adhere to it. Acids and alkalis have little result. This protects against deterioration damages. The surface area remains smooth. It does not react with usual commercial products. Wear is minimal under friction. Parts last much longer.

Machining is straightforward. You can get exact measurements easily. We make custom-made sizes and shapes. Think crucibles, tubes, nozzles, or insulators. Factories use it for steel handling. Semiconductor devices depend on its purity. Aerospace applications require its warm resistance. Furnace elements profit significantly.

It provides reputable defense. The product guards sensitive areas from extreme warm. Its reduced weight is a benefit. Handling and setup are easier. Lubricity is integral. Components slide versus each other efficiently.

(Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic)

Applications of Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

Custom-made boron nitride ceramic components manage extreme warm. They function well over 2000 ° C. This makes them essential for tough commercial tasks. Factories require products that won’t melt or damage down. BN ceramic fits this requirement perfectly.

Semiconductor manufacturers rely upon boron nitride crucibles. These crucibles hold liquified silicon or gallium arsenide. They keep the melt pure. BN ceramic doesn’t react with these hot fluids. It likewise protects electrically. This avoids short circuits during crystal development. Furnace components like setters and watercrafts use BN also. They lug silicon wafers via high-temperature actions. The ceramic holds up against the warm cycle after cycle.

Steel casting plants make use of BN ceramic finishings. Spraying it onto molds stops liquified aluminum or steel from sticking. This makes cleaner spreadings. Workers invest much less time cleansing mold and mildews. The finish also shields the mold and mildew from warm damages. Passes away last a lot longer. Shops conserve money on substitutes.

Aerospace and protection require products for severe conditions. BN ceramic goes into rocket engine parts. It lines nozzles facing extreme warm and friction. Plasma cutting torches make use of BN elements. These components direct the warm plasma jet. They have to endure unexpected temperature spikes. BN ceramic takes care of the thermal shock without splitting. It also works well in vacuum heaters.

Chemical processing utilizes BN for lining activators. It withstands strike from solid acids and molten salts. BN ceramic tubes and linings protect equipment. This maintains production running safely. The product doesn’t launch hazardous bits. It stays secure under destructive problems. Glass manufacturers make use of BN for parts touching liquified glass. It does not pollute the glass.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

What temperature can BN ceramic handle?

It withstands temperatures up to 2000°C in inert atmospheres. In air, it remains stable near 1000°C. This makes it suitable for extreme heat situations.

What shapes can you make this ceramic in?

Factories produce many shapes. Common forms include tubes, plates, crucibles, nozzles, and custom machined parts. Complex geometries are possible. Production methods like hot pressing or machining achieve this.

Where is high-temperature BN ceramic used?

Metal casting molds use it. Molten metal doesn’t stick to it. Semiconductor processing equipment needs it. It insulates well electrically. Aerospace components benefit from its stability. Furnace linings and thermocouple protection tubes are typical uses.

How is this different from regular ceramics?

It handles much higher heat than alumina or zirconia. It resists thermal shock exceptionally well. Rapid temperature changes won’t crack it easily. It’s also slippery. Metals don’t bond to it. It’s easy to machine precisely.

Are there handling precautions?

Handle it carefully. It’s strong but brittle. Avoid dropping it or impact. Use dry environments for storage. Moisture absorption weakens some grades. Always follow the manufacturer’s specific instructions. Wear gloves for sharp edges.

(Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

High Volume Resistivity Boron Nitride Ceramic Bn Rod for Machinery

High-Performance Boron Nitride Ceramic Pipe for Industrial Use

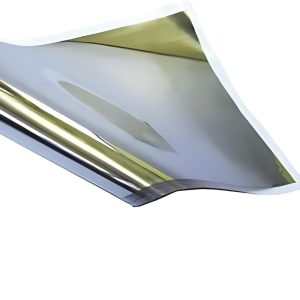

Chemically Stable Boron Nitride Ceramic BN Film

Hbn Custom Boron Nitride Ceramic Parts

High Purity 99.9% Boron Nitride Ceramic Heater element